A4 Mk3

| Exploded view - servicing gearbox cover |

| Special tools and workshop equipment required |

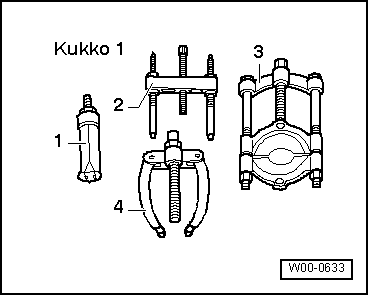

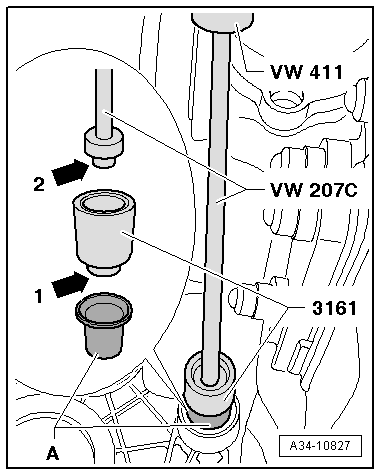

| t | Drift -VW 207 C- |

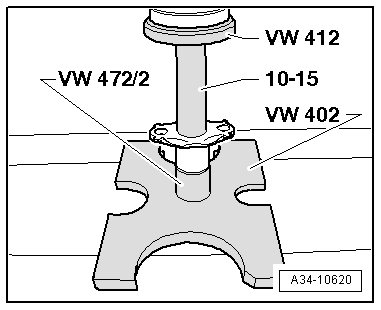

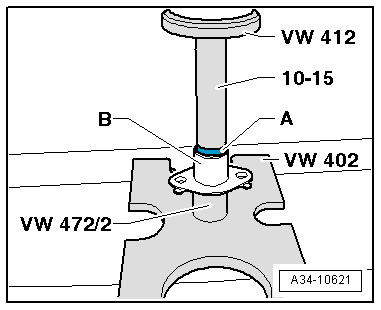

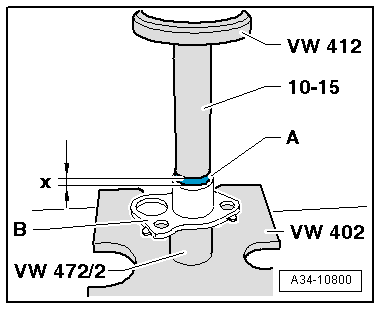

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

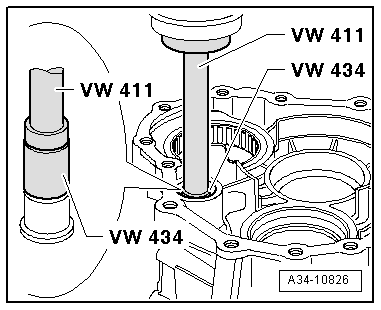

| t | Press tool -VW 411- |

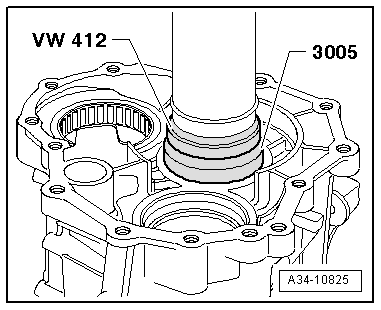

| t | Press tool -VW 412- |

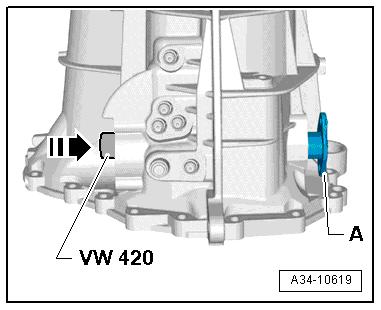

| t | Tube -VW 420- |

| t | Tube -VW 423- |

| t | Press tool -VW 434- |

| t | Thrust pieces for drive pinion bearing -VW 470- |

| t | Sleeve -VW 472/2- |

| t | Guide pin -10 - 15- |

| t | Press tool -40 - 20- |

| t | Thrust plate -3005- |

| t | Thrust pad -3062- |

| t | Extension -3161- |

| t | Assembly tool -3347- |

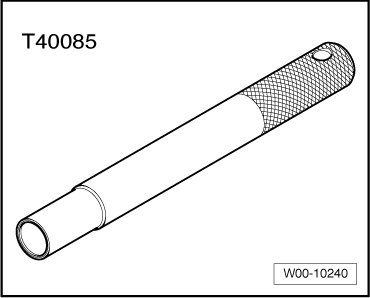

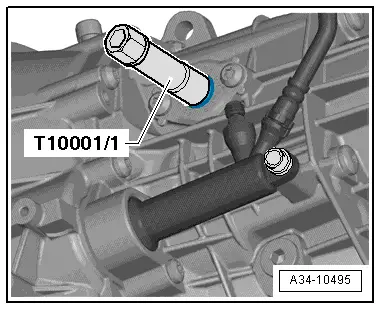

| t | Shock absorber set -T10001- |

| t | Extractor hook -T20143- |

|

|

|

|

|

|

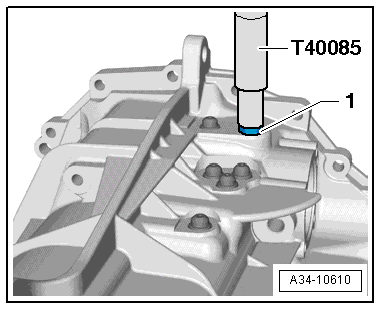

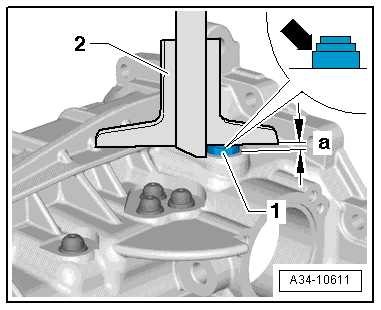

| 1 - | Large locking bush |

| q | For selector shaft |

| q | Removing and installing → Fig. |

| q | Installation depth → Fig. |

| 2 - | Locking bush |

| q | For selector plate / selector fork |

| q | At present there is no provision for removing and installing |

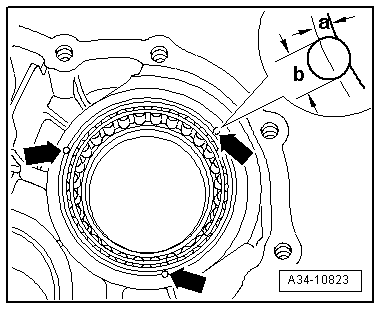

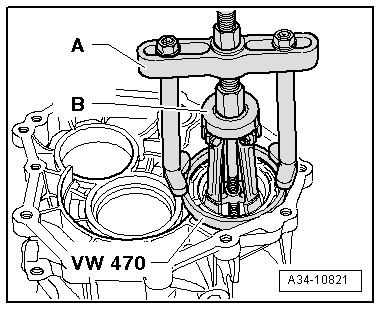

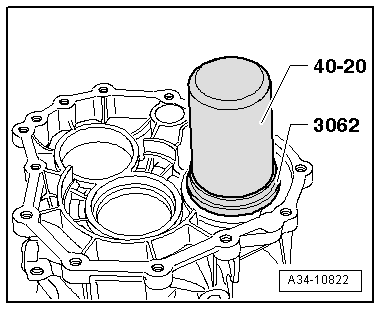

| 3 - | Needle bearing |

| q | For mounting output gear/spur gear mechanism |

| q | Extracting → Fig. |

| q | Always renew |

| q | Driving in → Fig. |

| q | Peen to secure after installing → Fig. |

| 4 - | Outer race/tapered roller bearing |

| q | For mounting input gear/spur gear mechanism in gearbox cover |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 5 - | Gearbox cover |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| 6 - | Oil filler plug |

| q | 40 Nm |

| 7 - | O-ring |

| q | Only installed in gearboxes with sealing cap/selector shaft in conjunction with gearbox neutral position sender -G701- or sealing plug |

| q | Always renew |

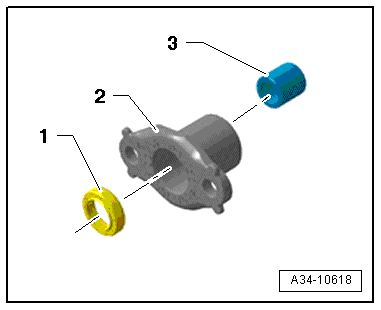

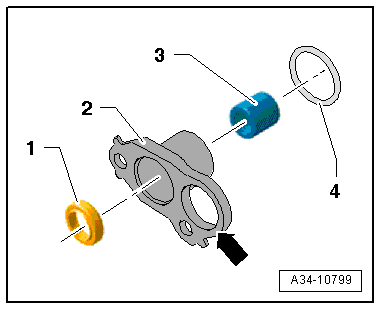

| 8 - | Sealing cap |

| q | For selector shaft in conjunction with gearbox neutral position sender -G701- or sealing plug |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Exploded view → Fig. |

| q | Removing and installing oil seal for selector shaft → Fig. |

| q | Removing ball sleeve for selector shaft → Fig. |

| q | Installing ball sleeve for selector shaft → Fig. |

| 9 - | Sealing plug |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Renew O-ring on sealing plug; select correct version according to gearbox code letters → Electronic parts catalogue |

| 10 - | Bolt |

| q | 24 Nm |

| q | Steel bolts (M8; 25 mm long) |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 11 - | Gearbox neutral position sender -G701- |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Renew O-ring on gearbox neutral position sender -G701-; select correct version according to gearbox code letters → Electronic parts catalogue |

| 12 - | Sealing cap |

| q | For selector shaft without gearbox neutral position sender -G701- or sealing plug |

| q | Not fitted on all versions |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Removing and installing → Fig. |

| q | Exploded view → Fig. |

| q | Removing and installing oil seal for selector shaft → Fig. |

| q | Removing ball sleeve for selector shaft → Fig. |

| q | Installing ball sleeve for selector shaft → Fig. |

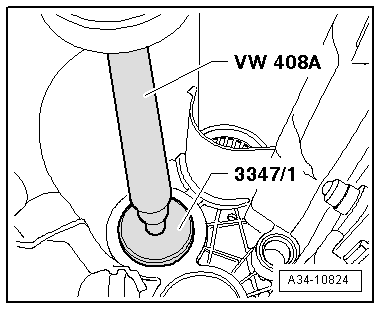

| 13 - | Bearing bush |

| q | For 3rd/4th gear selector plate / selector fork |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 14 - | Small locking bush |

| q | For selector shaft |

| q | At present there is no provision for removing and installing |

| 15 - | Breather pipe |

| q | Installation dimension: 17.5 mm ± 0.5 mm from upper edge of pipe on housing |

| q | Clip in cap for gearbox breather |

| 16 - | Cap |

| q | For gearbox breather |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|