| t

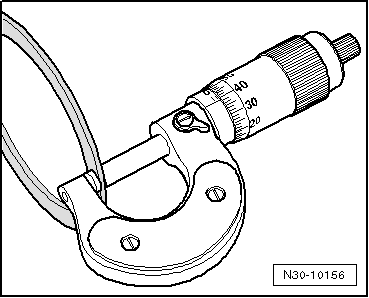

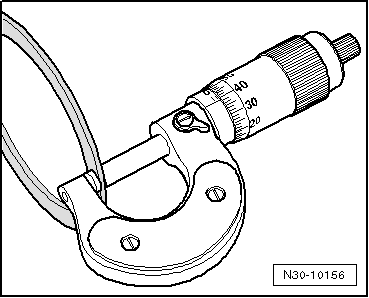

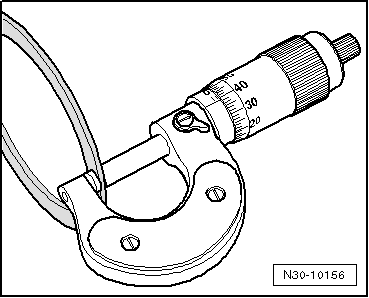

| Use a micrometer to measure the shims at several points. Tolerance variations make it possible to obtain the exact shim thickness required. |

| t

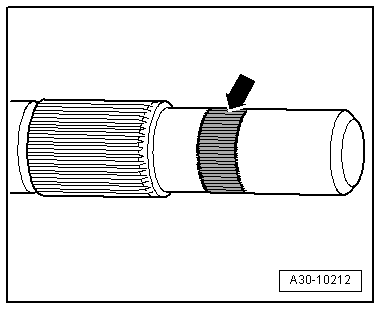

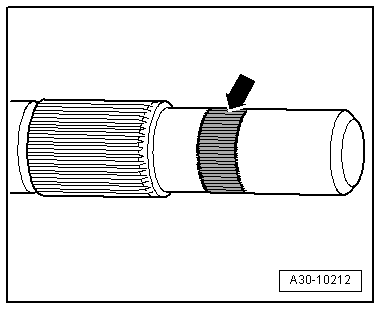

| Check for burrs and damage. |

| t

| Do not install shims which are damaged or not in perfect condition. |

| t

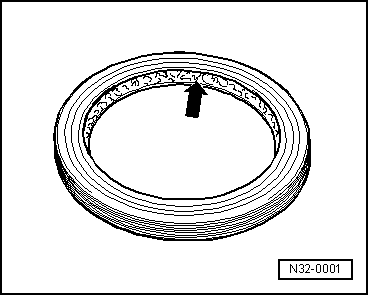

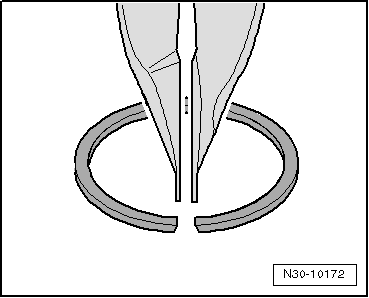

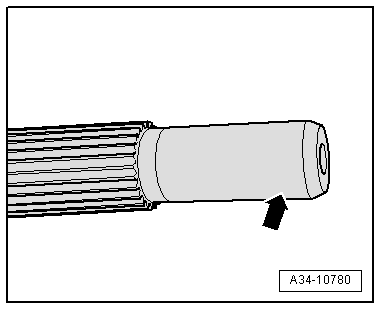

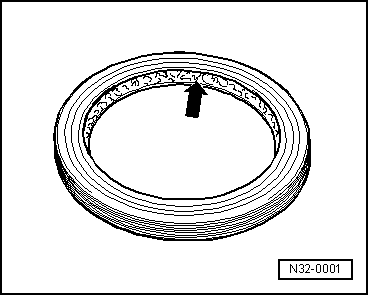

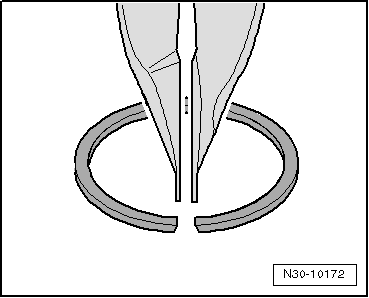

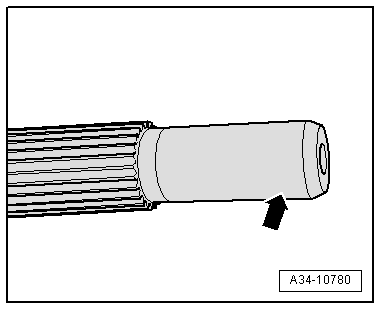

| Install needle bearings, ball sleeves and roller bearings so the lettering (side with thicker metal) faces towards the installing tool. |

| t

| Lubricate all bearings in gearbox with gear oil when installing. |

| t

| On installation, heat the inner races of tapered roller bearings to approx. 100 °C with the inductive heater -VAS 6414-. When fitting, press home with no axial clearance. |

| t

| Heat inner races of needle bearings and roller bearings to max. 130 °C. |

| t

| Do not interchange the outer or inner races of bearings of the same size (the bearings are paired). |

| t

| If required, renew the tapered roller bearings on one shaft together and use new bearings from a single manufacturer. |

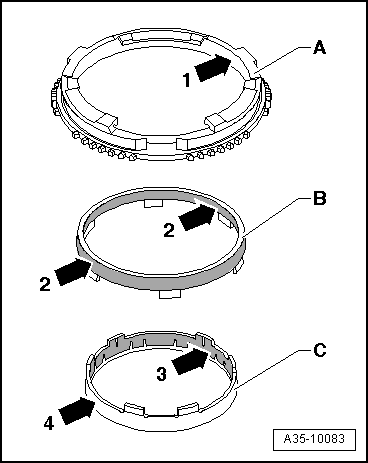

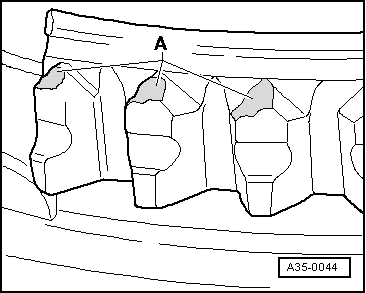

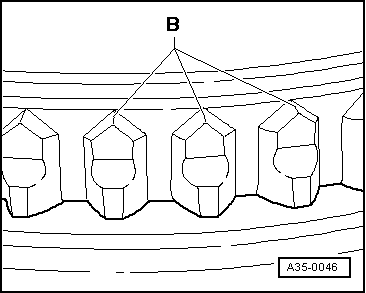

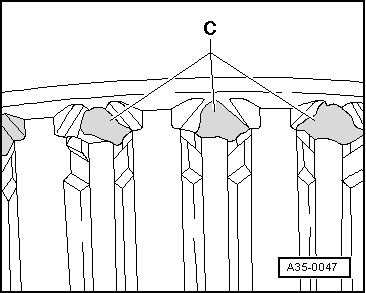

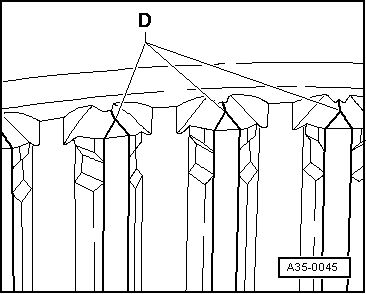

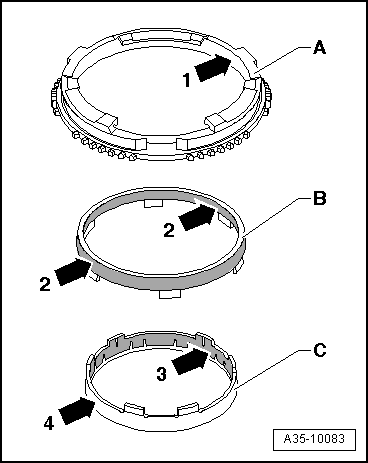

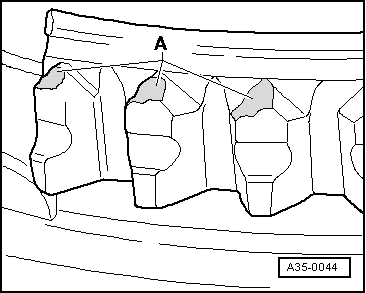

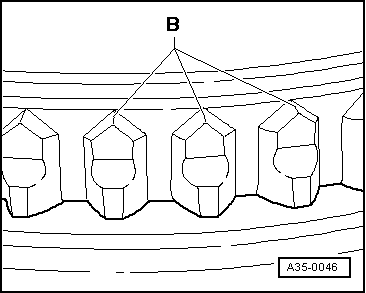

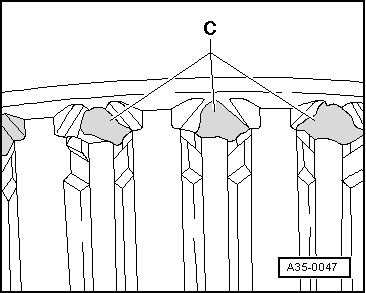

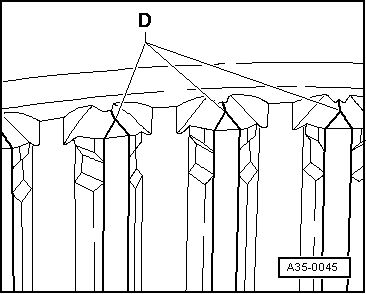

| Gears, synchronising hubs, inner rings for selector gears |

| t

| On installation, heat the inner rings for selector gears to approx. 100 °C with the inductive heater -VAS 6414-. |

| t

| On installation, heat the synchronising hubs to approx. 100 °C with the inductive heater -VAS 6414-. When fitting, press home with no axial clearance. |

| t

| On installation, heat the gears to approx. 150 °C with the inductive heater -VAS 6414-. When fitting, press home with no axial clearance. |

| t

| Note correct installation position. |

| t

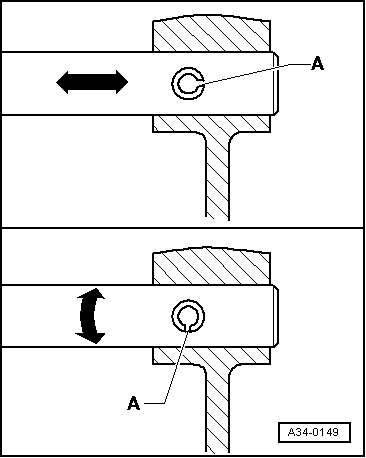

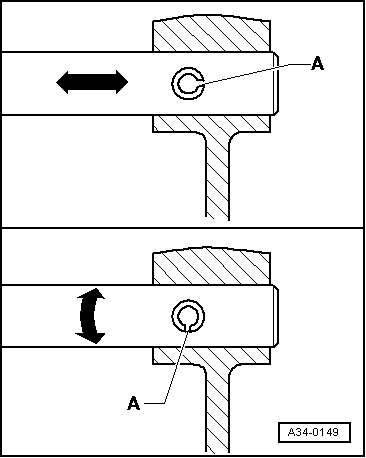

| After installing, check that 1st to 6th speed selector gears have an axial clearance of 0.15 ... 0.50 mm and check that they rotate freely. |

|

|

|