A4 Mk3

| Assembly sequence - removing and installing selector fork cluster, input shaft, 1st, 2nd and reverse gears on output shaft |

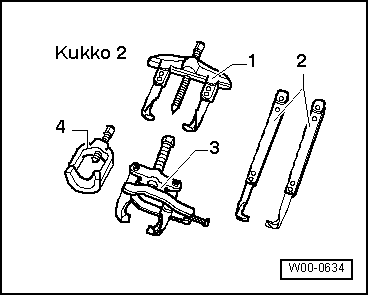

| Special tools and workshop equipment required |

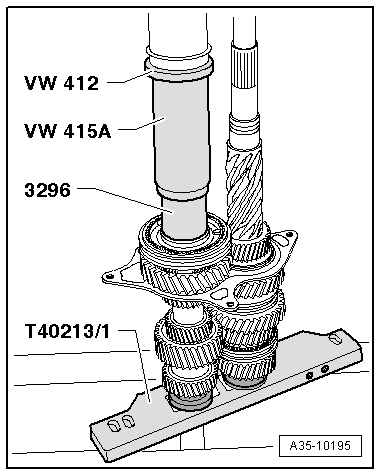

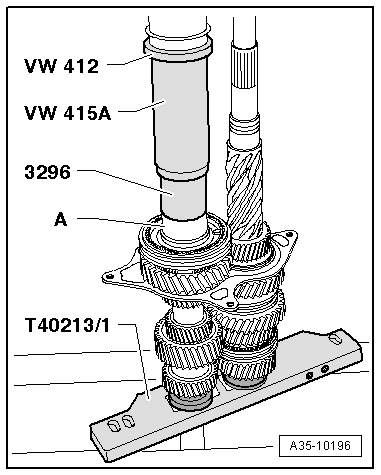

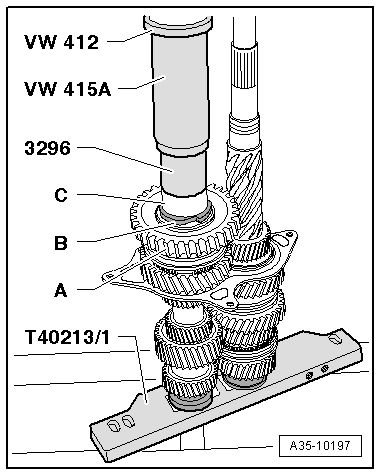

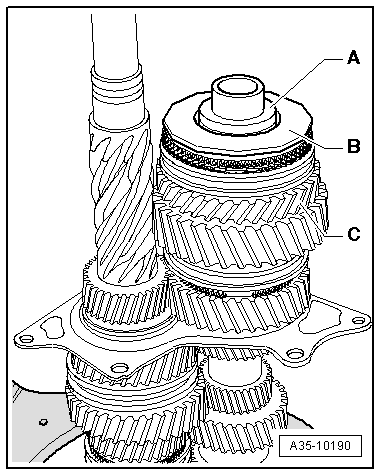

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

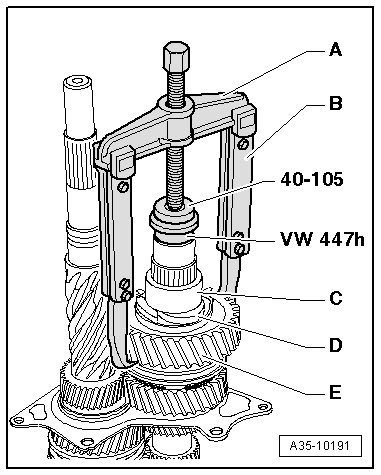

| t | Thrust plate -VW 447 H- |

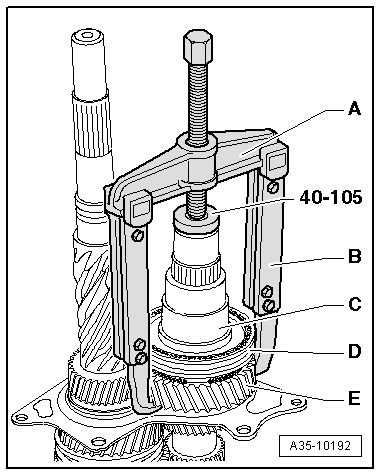

| t | Thrust plate -40 - 105- |

| t | Tube -3296- |

| t | Workshop press -V.A.G 1290A- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Caution

Caution