A4 Mk3

|

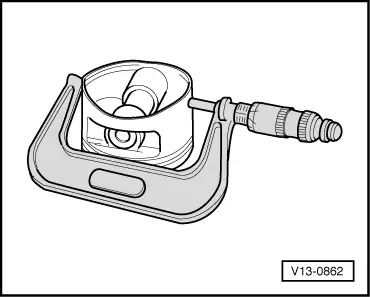

| Piston Ø mm | |||

| Nominal dimension | 82.924 … 82.936 1) | ||

| Repair oversize | 82.964 … 82.976 1) | ||

| |||

|

|

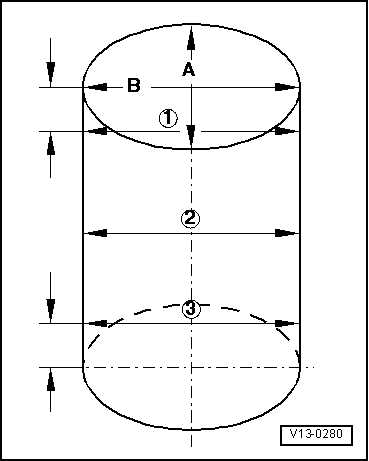

| Cylinder bore Ø mm | |||

| Nominal dimension | 83.006 … 83.014 1) | ||

| Repair oversize | 83.046 … 83.054 1) | ||

| |||

|

|

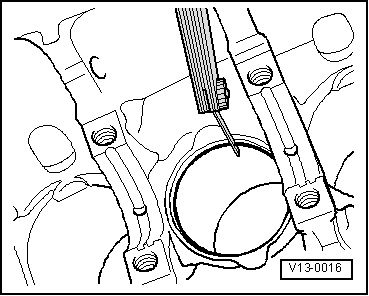

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.25 … 0.40 | 0.60 |

| 2nd compression ring | 0.70 … 0.90 | 1.20 |

| Oil scraper ring | 0.25 … 0.50 | 0.70 |

|

|

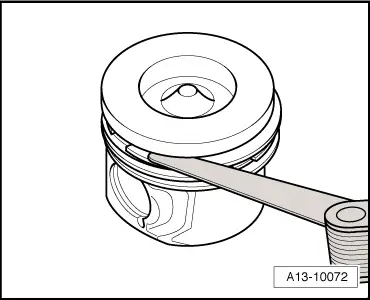

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.009 … 0.130 | 0.160 |

| 2nd compression ring | 0.05 … 0.09 | 0.11 |

| Oil scraper ring | 0.03… 0.07 | 0.10 |