| –

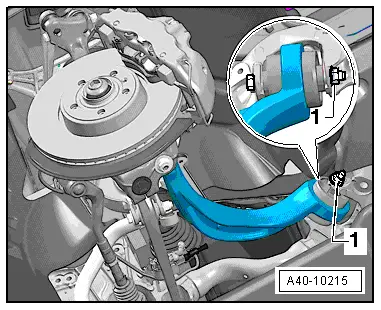

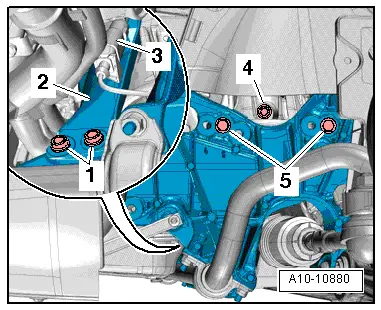

| Press subframe into place at markings -C- and -D-. Tighten bolts -5- and -8- to specified torque. |

| –

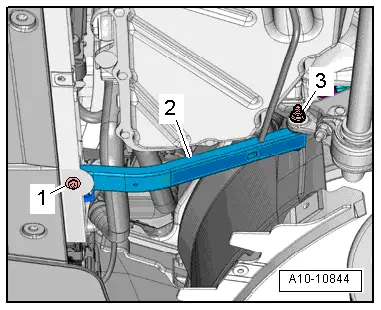

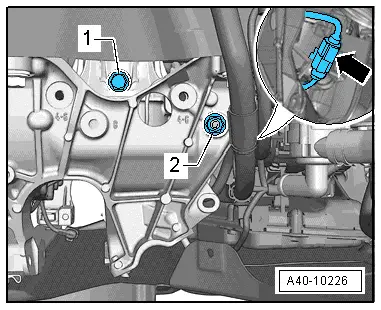

| Screw in bolts -1-, -4-, -6- and -7- and tighten to specified torque. |

| –

| Tighten bolts -1- to -8- through specified angle to final setting. |

Note | t

| Bonded rubber bushes can only be turned to a limited extent. The suspension mountings must therefore only be tightened when the suspension is in the unladen position or reference position. |

| –

| On vehicles with automatic headlight range control, carry out basic adjustment of headlights → Rep. gr.94. |

| –

| If the reference position has been re-adapted on vehicles with lane departure warning, the lane departure warning control unit -J759- must be recalibrated → Chapter. |

| –

| Wheel alignment must be checked and adjusted, see chart → Chapter. |

|

|

|

Note

Note

Note

Note