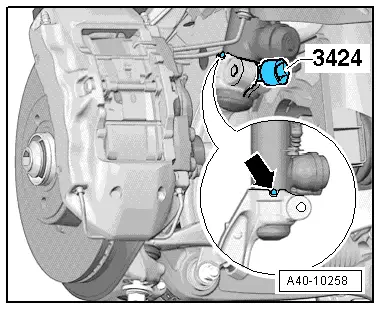

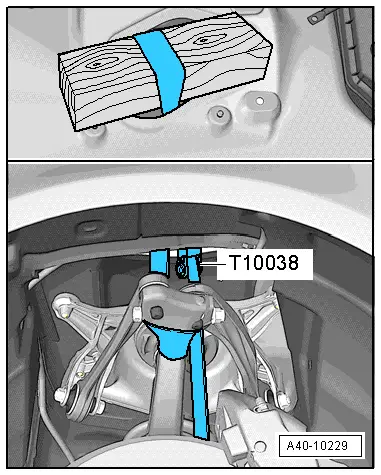

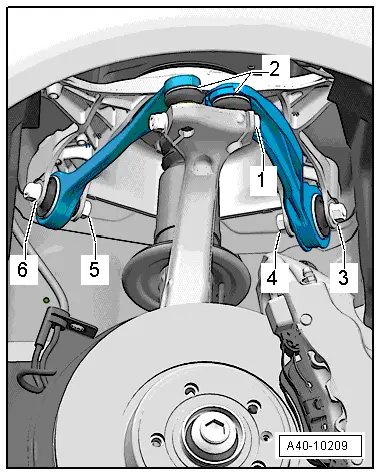

| When fitting, ensure T-bolt -arrow- engages in groove of shock absorber fork. |

Note | Bonded rubber bushes can only be turned to a limited extent. The suspension mountings must therefore only be tightened when the suspension is in the unladen position or reference position. |

| –

| On vehicles with automatic headlight range control, carry out basic adjustment of headlights → Rep. gr.94. |

| –

| If the reference position has been re-adapted on vehicles with lane departure warning, the lane departure warning control unit -J759- must be recalibrated → Chapter. |

| –

| Wheel alignment must be checked and adjusted, see chart → Chapter. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note