A5

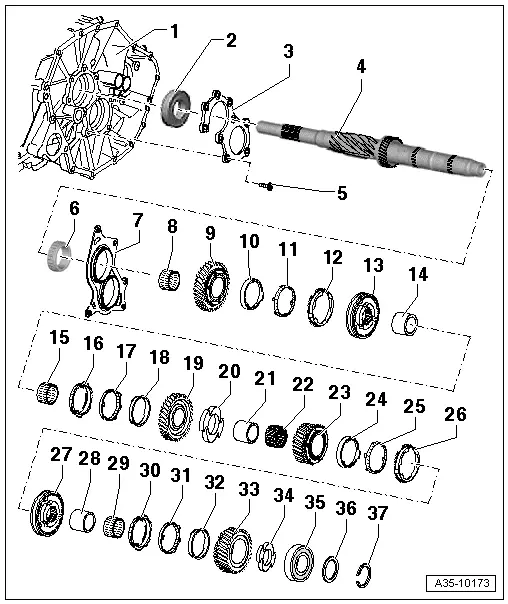

| Exploded view - input shaft |

| Detaching input shaft from output shaft and bearing mounting → Chapter „Exploded view - detaching selector fork cluster, input shaft, first, second and reverse gear from output shaft/attaching “. |

| Fitting sequence - dismantling and assembling input shaft → Chapter. |

Note

Note| t | When fitting new gears or the input shaft, heed the technical data → 6-speed manual gearbox 0B3, front-wheel drive; Rep. Gr.00. |

| t | When replacing synchro-rings, the inner ring, intermediate ring and synchro-ring must be jointly replaced for each gear. |

| t | Lubricate all bearings and synchro-rings on input shaft with gear oil before installing. |

| t | 3rd to 6th speed selector gears should have an axial play of 0.15 ... 0.50 mm after installing. |

| 1 - | Gearbox housing |

| 2 - | Ball bearing |

| q | For input shaft |

| q | Removing and installing → Item |

| 3 - | Plate |

| q | For securing ball bearings in gearbox housing |

| 4 - | Input shaft |

| q | With splines for 1st, 2nd and reverse gear |

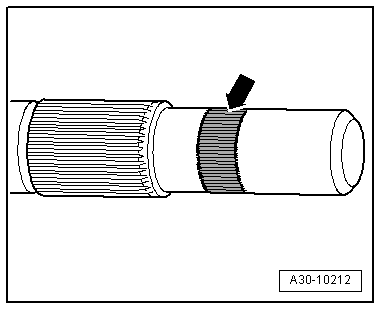

| q | Checking input shaft for wear → Fig. |

| 5 - | Bolt |

| q | Tightening torque → Item |

| 6 - | Roller bearing |

| q | For input shaft |

| q | Pressing off → Anchor |

| q | Pressing on → Anchor |

| 7 - | Bearing mounting |

| q | Carries bearings for input shaft and output shaft in gearbox cover |

| q | → Item |

| 8 - | Needle bearing |

| q | For 5th gear |

| 9 - | 5th speed selector gear |

| 10 - | Inner ring for 5th gear |

| q | Installation position → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 11 - | Intermediate ring for 5th gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 12 - | Synchro-ring for 5th gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Replace if scored or if there are visible traces of wear |

| 13 - | Locking collar/synchronising hub for 5th and 6th gear |

| q | Installation position: High collar on inside of synchronising hub facing 5th speed selector gear |

| q | Pressing off → Anchor |

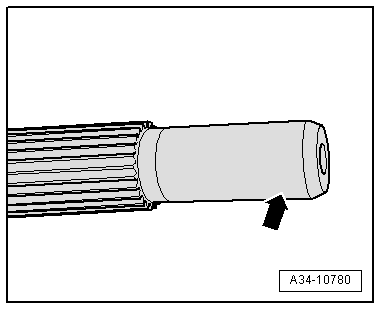

| q | Pressing on → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. |

| 14 - | Inner race/needle bearing |

| q | For 6th speed selector gear |

| q | Pressing off → Anchor |

| q | Pressing on → Fig. |

| 15 - | Needle bearing |

| q | For 6th gear |

| 16 - | Synchro-ring for 6th gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Replace if scored or if there are visible traces of wear |

| 17 - | Intermediate ring for 6th gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 18 - | Inner ring for 6th gear |

| q | Installation position → Fig. |

| q | Replace if scored or if there are visible traces of wear |

| 19 - | 6th speed selector gear |

| 20 - | Thrust washer |

| q | For 3rd speed and 6th speed selector gears |

| 21 - | Needle bearing inner race |

| q | For 3rd gear |

| q | Pressing off → Anchor |

| q | Pressing on → Anchor |

| 22 - | Needle bearing |

| q | For 3rd gear |

| 23 - | 3rd speed selector gear |

| 24 - | Inner ring for 3rd gear |

| q | Installation position → Fig. |

| q | Replace if scored or if there are visible traces of wear |

| 25 - | Intermediate ring for 3rd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 26 - | Synchro-ring for 3rd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Replace if scored or if there are visible traces of wear |

| 27 - | Locking collar/synchronising hub for 3rd and 4th gear |

| q | Pressing off → Anchor |

| q | Pressing on → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. |

| 28 - | Needle bearing inner race |

| q | For 4th gear |

| q | Pressing off → Anchor |

| q | Pressing on → Fig. |

| 29 - | Needle bearing |

| q | For 4th gear |

| 30 - | Synchro-ring for 4th gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Replace if scored or if there are visible traces of wear |

| 31 - | Intermediate ring for 4th gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 32 - | Inner ring for 4th gear |

| q | Installation position → Fig. |

| q | Replace if scored or if there are visible traces of wear |

| 33 - | 4th speed selector gear |

| 34 - | Thrust washer |

| q | For 4th speed selector gear |

| 35 - | Ball bearing |

| q | Pressing off → Anchor |

| q | Pressing on → Anchor |

| 36 - | Shim |

| q | Determining thickness → Anchor |

| 37 - | Circlip |

|

|

|

|