Discovery II

EMISSION CONTROL - V8

17-2-48 DESCRIPTION AND OPERATION

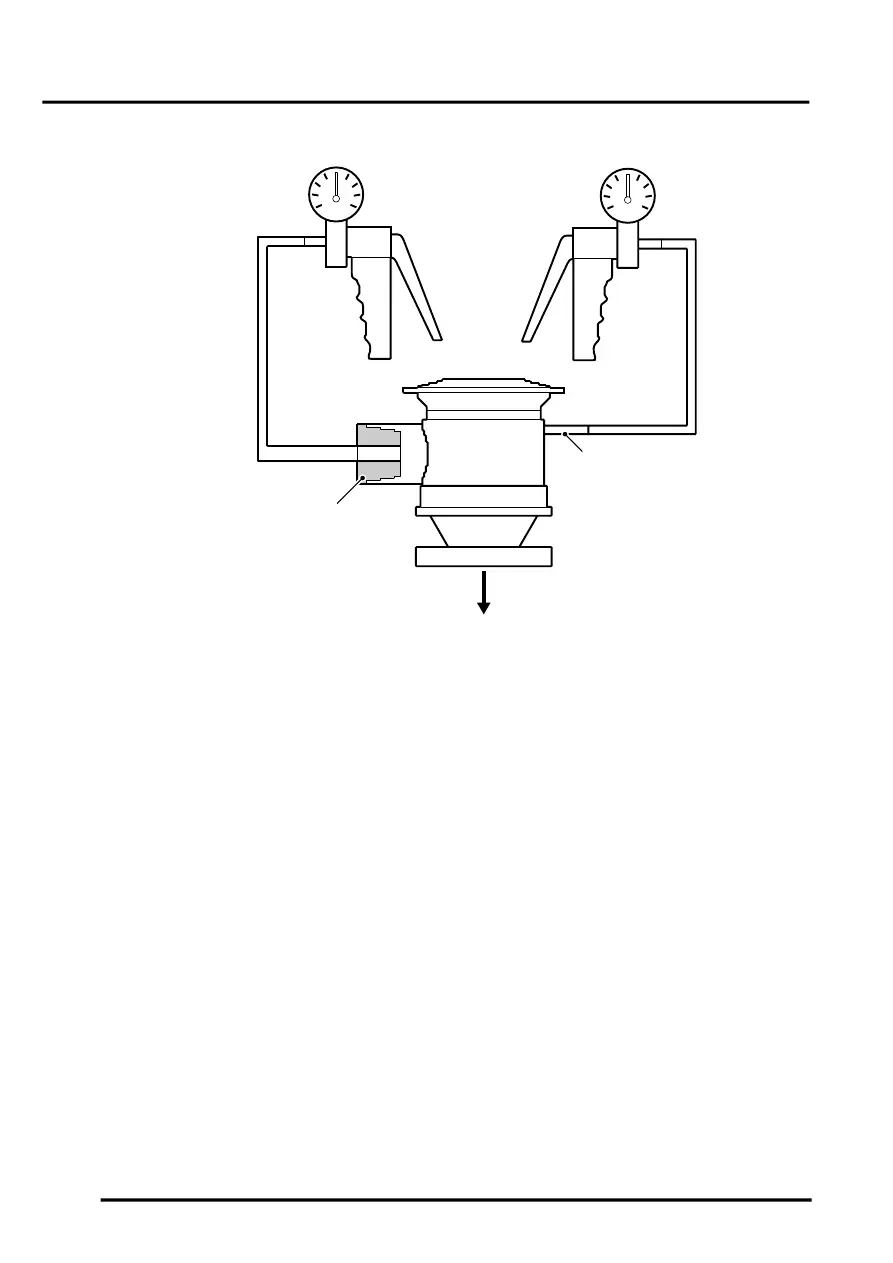

Test 2 – Secondary Air Injection (SAI) Control Valves

1 SAI control valve

2 Pressure connection

3 Outlet

4 Inlet connection stopper

5 Hand pressure pump

6 Hand vacuum pump

Visually inspect the SAI control valve for external damage.

Leak Test

Remove the line from the inlet connection and connect the hand pressure pump (5) using the inlet connection stopper

(4). Using the hand pressure pump, pressurise the SAI control valve with 100 mBar (1.45 lbf/in

2

) pressure. Maximum

permissable pressure drop at the hand pressure pump gauge 10 mbar/minute (0.145 lbf/in

2

/minute) with the outlet (3)

open.

Valve Opening Test

Connect the hand vacuum pump (6) to the control pressure connection (2). Depressurise the pressure connection

using the hand vacuum pump. When the vacuum reaches -300 mbar (-4.35 lbf/in

2

), the SAI control valve (1) must

open and the pressure on the hand pressure pump (5) gauge should drop suddenly.

Tightness of Diaphragms

The available pressure difference (vacuum) at the control pressure connection (2) must not drop over a period of time

(Refer to Valve Opening Test).

NOTE: In the case of a leaking or incorrectly controlled SAI control valve, the inlet connection is usually heavily fouled

and a condensate smell is noticeable on the hose line to the SAI pump.

If, after switching off the SAI pump, pulsation noise is still noticeable at the SAI pump, the SAI control valve and

delivery hoses must be replaced before fitting a new SAI pump.

M17 0376

3

6

5

1

4

2