Freelander Service Procedures

GENERAL INFORMATION

03-15

Fuel System Hoses

All fuel hoses are made up of two laminations, an

armoured rubber outer sleeve and an inner viton

core. If any of the fuel system hoses have been

disconnected, it is imperative that the internal bore is

inspected to ensure that the viton lining has not

become separated from the armoured outer sleeve.

A new hose must be fitted if separation is evident.

Cooling system hoses

The following precautions MUST be followed to

ensure that integrity of cooling hoses and their

connections to system components are maintained.

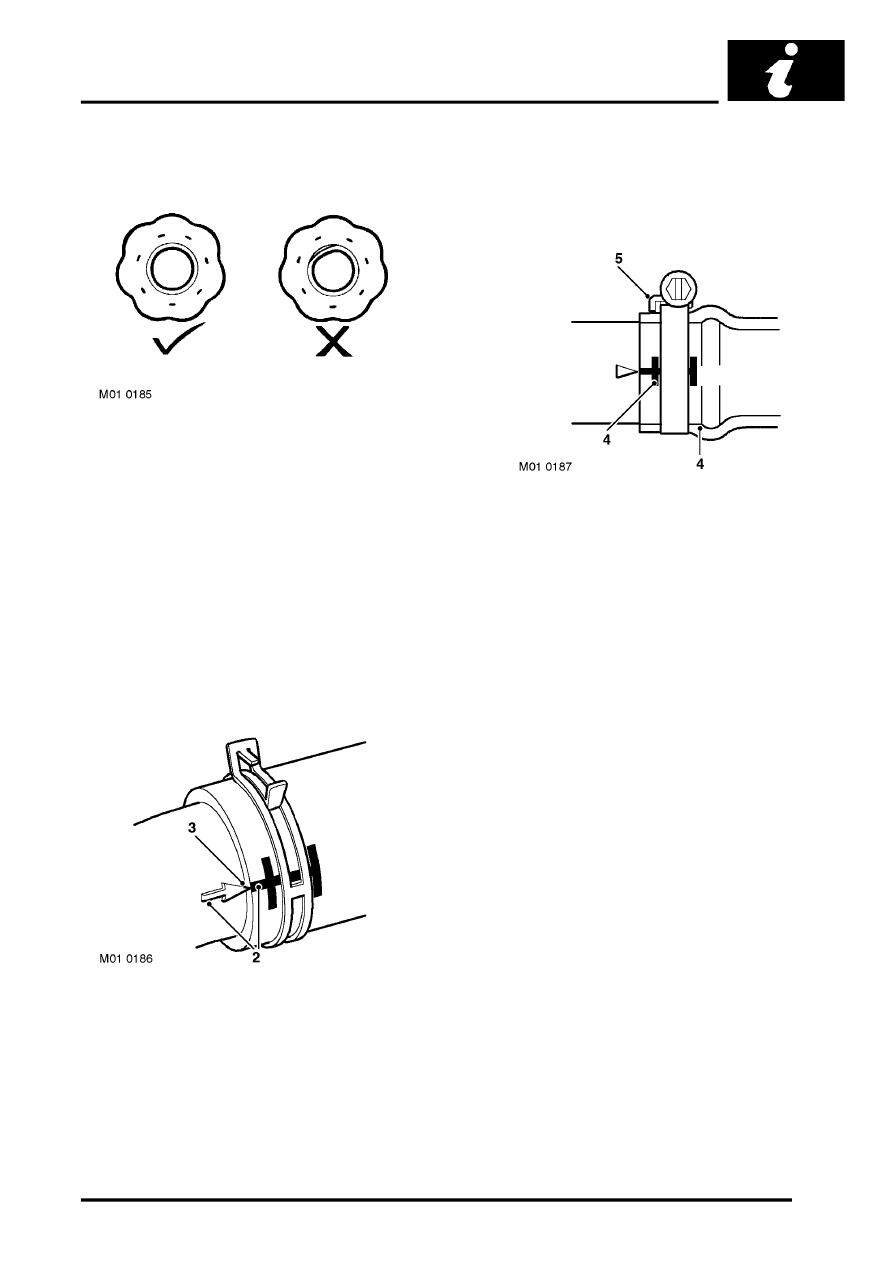

Hose orientation and connection

Correct orientation of cooling hoses is important in

ensuring that the hose does not become fatigued or

damaged through contact with adjacent

components.

Where 'timing' marks (2) are provided on the hose

and corresponding connection, these must be used

to ensure correct orientation.

Hoses must be pushed fully onto their connection

points. Usually, a moulded form (3) on the stub pipe

provides a positive indicator.

Hose clips

Markings (4) are usually provided on the hose to

indicate the correct clip position. If no markings are

provided, position the clip directly behind the

retaining lip at the end of the stub as shown.

Worm drive clips should be oriented with the crimped

side of the drive housing (5) facing towards the end

of the hose, or the hose may become pinched

between the clip and the stub pipe retaining lip.

Worm drive clips should be tightened to 3 Nm (2

lbf.ft) unless otherwise stated.

Ensure that hose clips do not foul adjacent

components.