Renew Starter Ring Gear for V8 Engine Overhaul - 35, 39, 42

ENGINE

OVERHAUL

43

Starter ring gear - renew

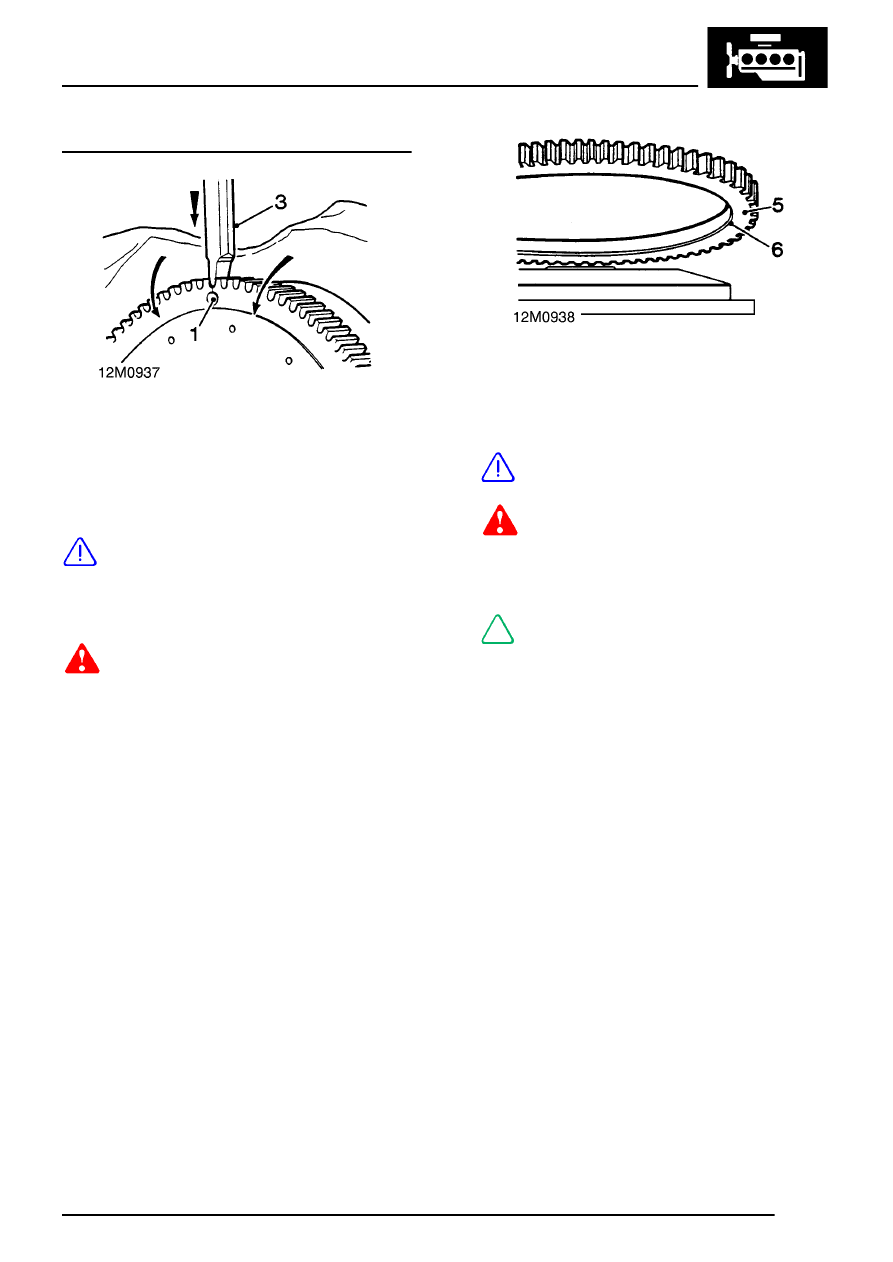

1. Drill a 9.5 mm (0.375 in) diameter hole axially

at base of tooth and inner diameter of starter

ring, sufficiently deep enough to weaken ring

gear.

CAUTION: Do not allow drill to enter

flywheel.

2. Secure flywheel in soft jawed vice.

3. Split ring gear using a cold chisel.

WARNING: Wear safety goggles and take

precautions against flying fragments when

splitting ring gear.

4. Remove flywheel from vice, remove old ring

gear, and place flywheel, clutch side down, on

a flat surface.

5. Heat new ring gear uniformly to between 170

°

and 175

°

C (340

°

and 350

°

F).

CAUTION: Do not exceed this

temperature.

WARNING: Handle hot ring gear with care.

6. Locate ring gear on flywheel with chamfered

inner diameter towards flywheel flange.

NOTE: If ring gear is chamfered on both

sides, it can be fitted either way round.

7. Press ring gear on to flywheel until it butts

against flywheel flange.

8. Allow flywheel to air cool.