Intrigue V6-3.8L VIN K (1998)

Connecting Rod Bearing: Service and Repair

Connecting Rod Bearing Replacement

REMOVAL PROCEDURE

^

Tools Required

-

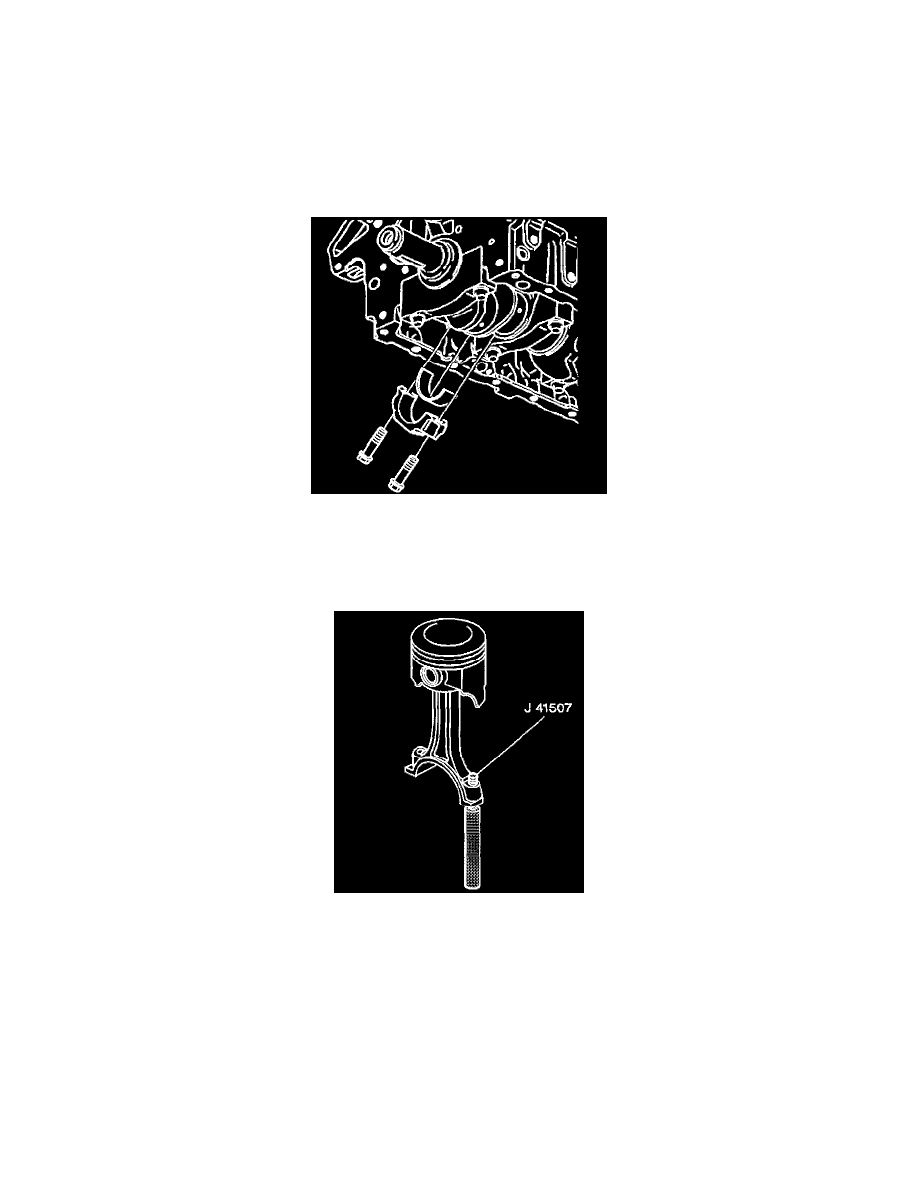

J 41507 Connecting Rod Assembly Guide

1. Remove the oil pan.

2. Position the connecting rod to be serviced to Bottom Dead Center (BDC) by rotating the crankshaft.

3. Remove the connecting rod cap bolts.

4. Remove the connecting rod cap and lower connecting rod bearing.

5. Remove the lower connecting rod bearing from the connecting rod cap.

IMPORTANT: Keep the bearings with the original connecting rod and cap. Do this in order to reassemble the connecting rod.

6. Install the J41507 to the connecting rod.

7. Use the J 41507, in order to push up the connecting rod and piston and access the upper connecting rod bearing.

8. Remove the upper connecting rod bearing.

9. Wipe the oil from the bearings.

10. Inspect the connecting rod bearings.

11. Measure the bearing clearance.

INSTALLATION PROCEDURE

^

Tools Required

-

J 36660 Electronic Torque Angle Meter

-

J 41507 Connecting Rod Assembly Guide

1. Dip the connecting rod cap bolts in clean engine oil.