| Disassemble and assemble the synchromesh assembly of the 1st and 2nd gear |

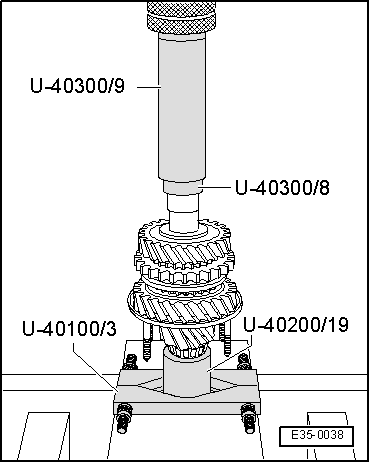

| –

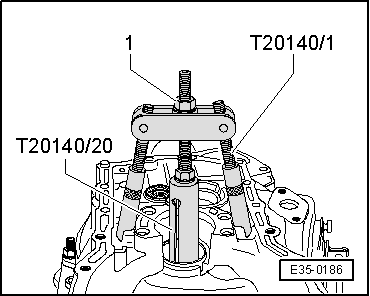

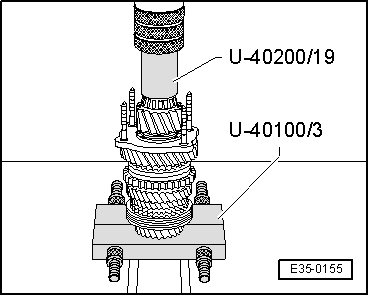

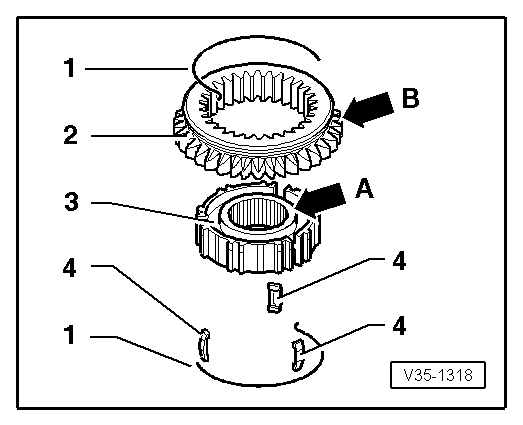

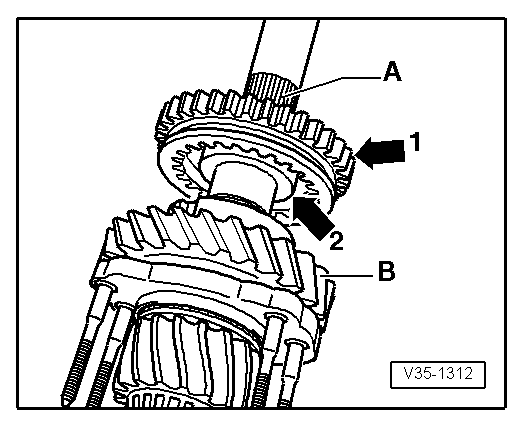

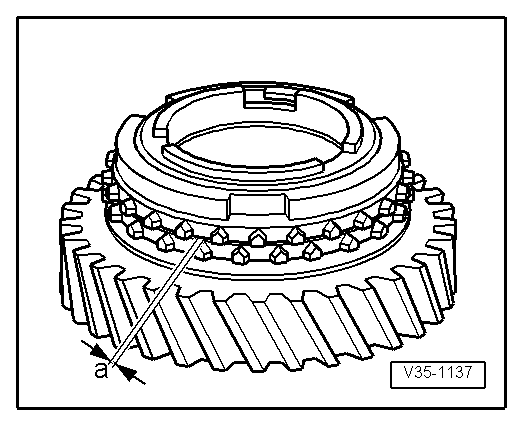

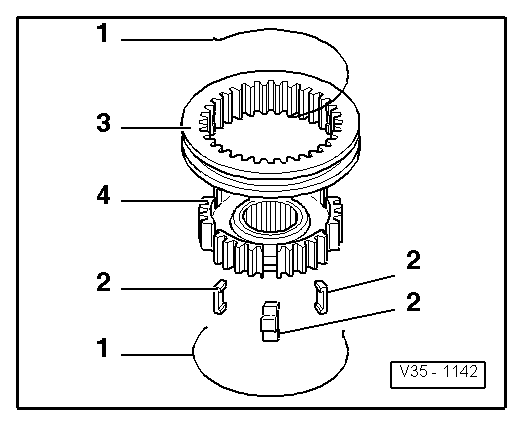

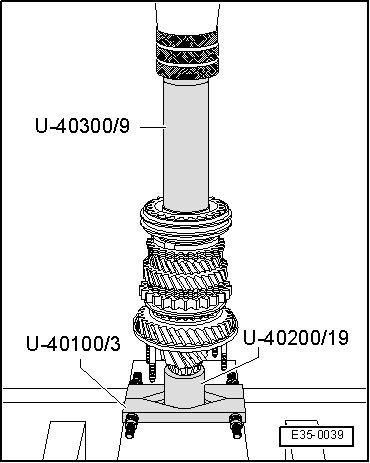

| To remove the synchromesh assembly of the 1st and 2nd gear, remove the springs -1- and move the sliding sleeve -2- completely upwards. |

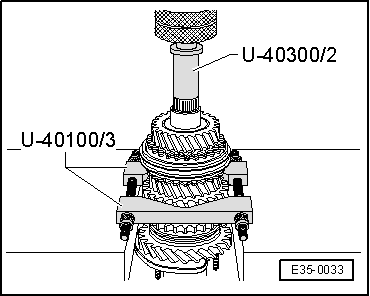

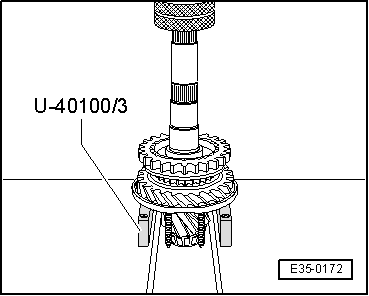

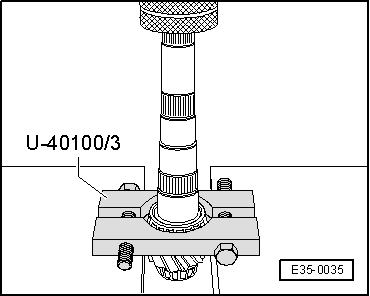

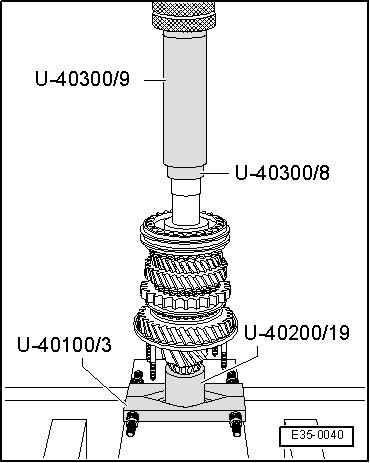

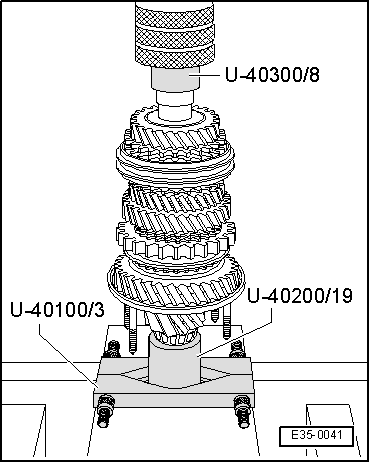

| Fit the synchromesh assembly of 1st and 2nd gear in the following way: |

| –

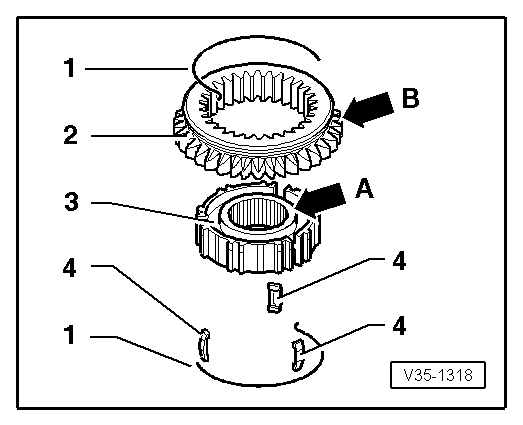

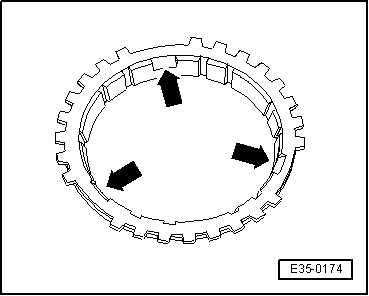

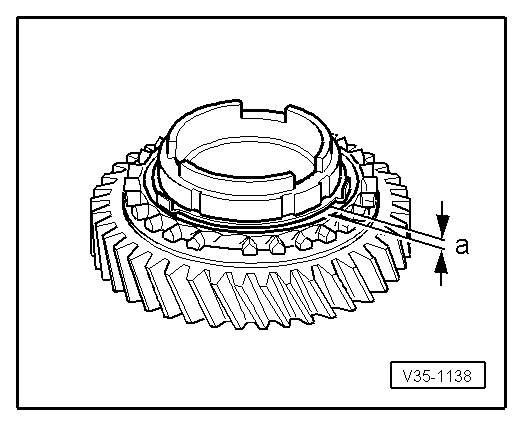

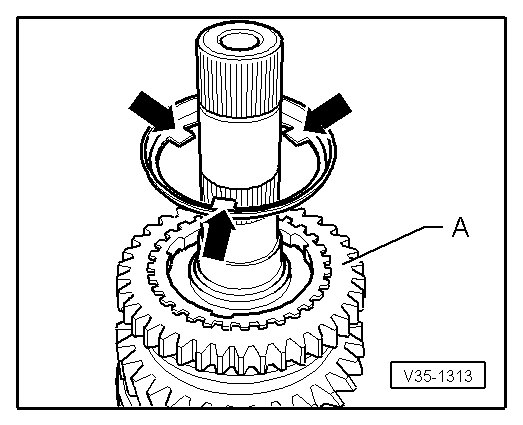

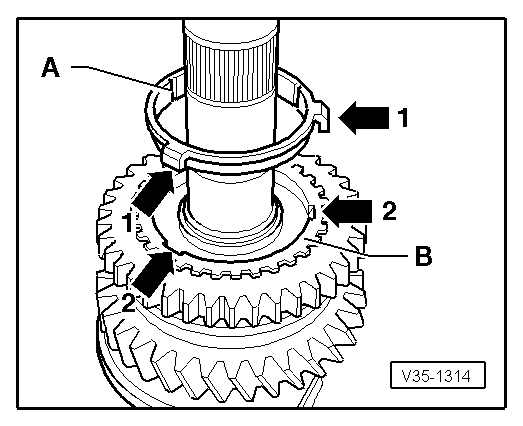

| Place the mobile sleeve -2- on the synchromesh hub -3-, so that the grooves for the locking pins -4- on both components coincide. |

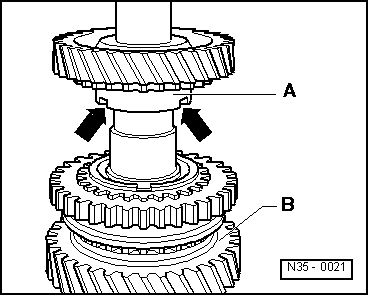

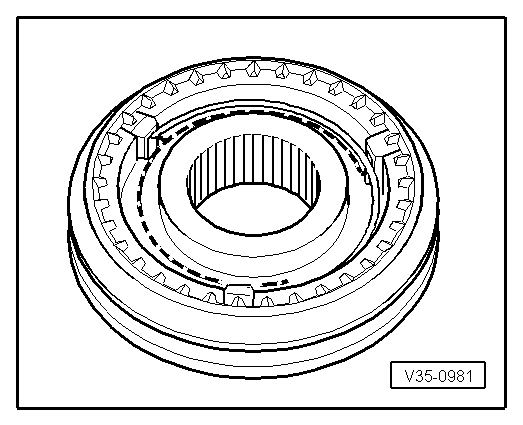

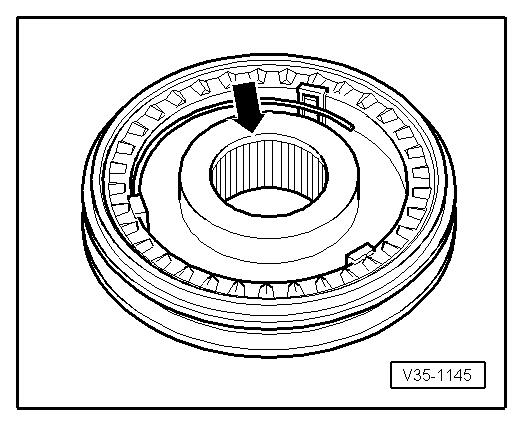

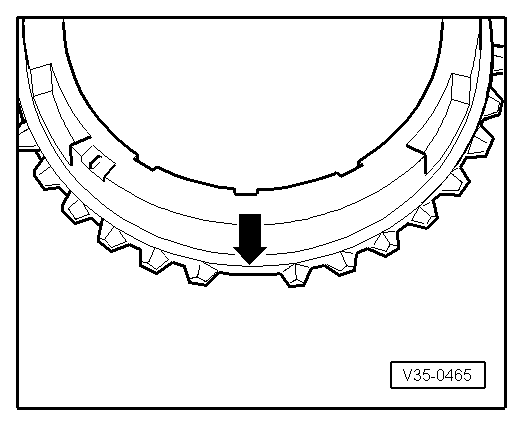

| Install the mobile sleeve on the synchromesh hub, so that after assembly they are situated with the widest collar on the synchromesh hub -A-, and the outer cogs on the slide -B- facing opposite directions. |

|

|

|

Note

Note