| Checking tapered pulleys for pulley set „II“ |

| –

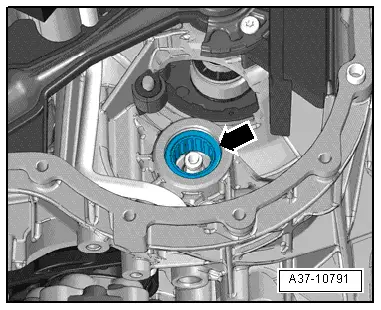

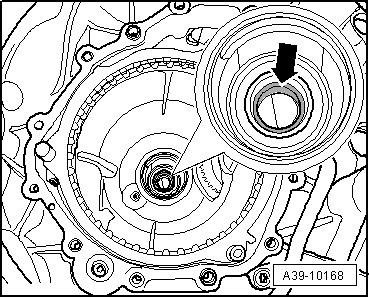

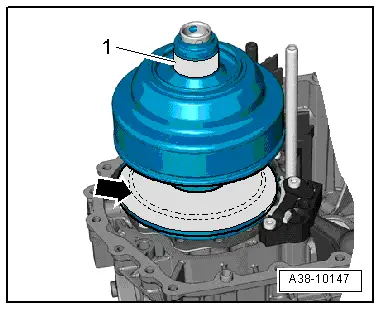

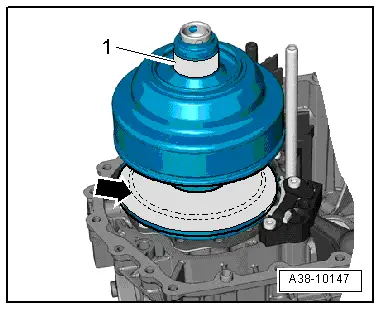

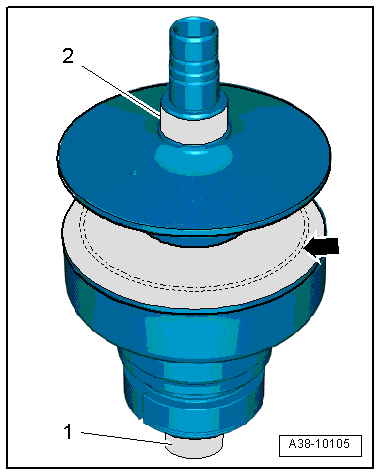

| Check that tapered pulleys -arrow- for pulley set „II“ are smooth with no traces of scoring. |

| –

| Run your finger nail from inside to outside over entire surface of tapered pulley to assess damage on running surface. |

| l

| Any very slight scores or damage that cannot be felt with the finger nail can be disregarded. |

| l

| If you feel any scores or damage with your finger nail, or if your nail catches, renew gearbox. |

| –

| Perform an additional visual inspection. |

| l

| The gearbox must be renewed if there are any individual scores which appear polished (mirrored) with black edges. |

|

|

|

Note

Note

Note

Note