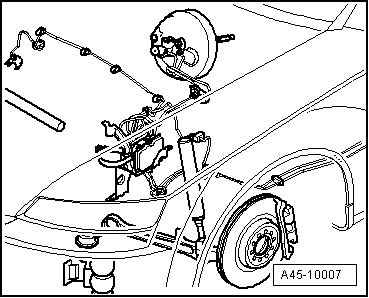

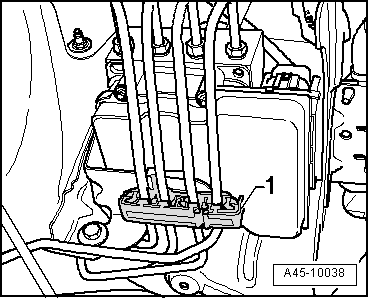

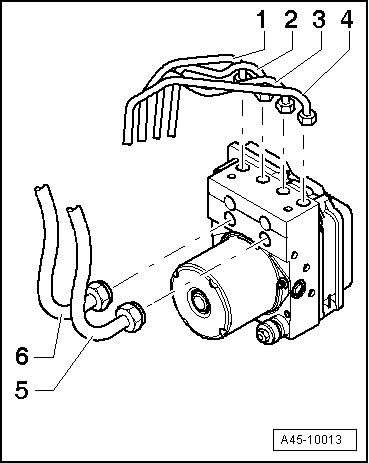

| No guarantee is given for hydraulic units without transport protection. |

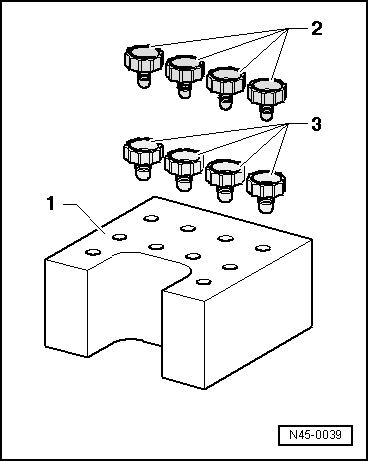

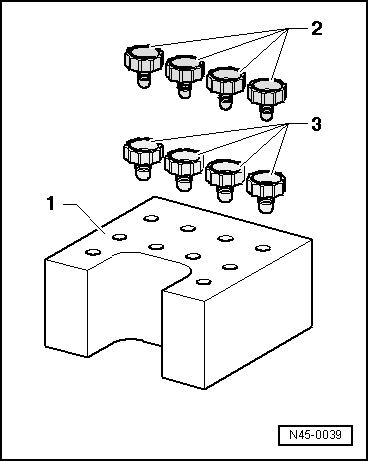

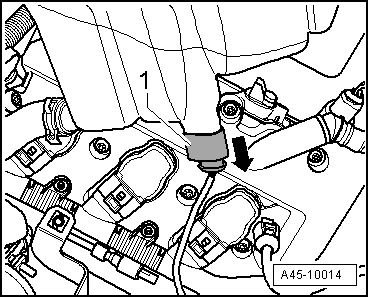

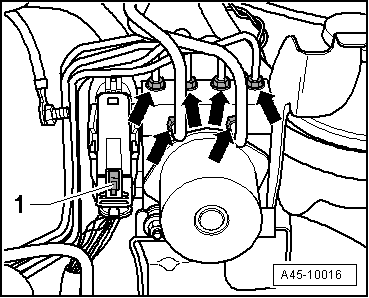

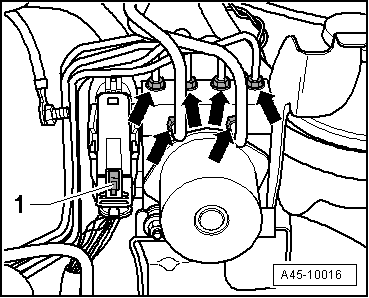

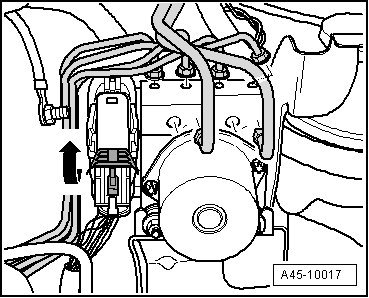

| 1 - | Transport protection for the valve stems (cellular plastic) |

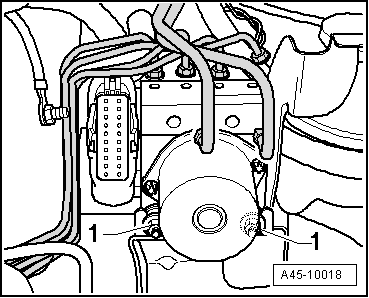

WARNING | The brake lines should not be folded or kinked in area of the hydraulic unit |

|

Note | t

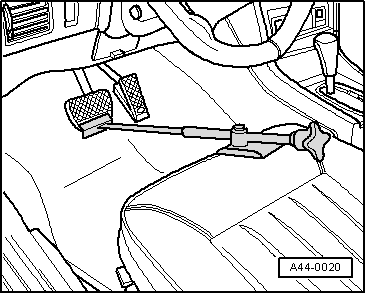

| Before disconnecting the battery, consult the customer regarding the anti-theft code provided with the radio. |

| t

| If the battery is reconnected check the vehicle equipment (radio, clock, electric comfort system, etc.), following the indications in the Workshop Manual and/or the Operating Instructions. |

WARNING | Before working on the electrical system, disconnect the battery earth strap. |

|

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING