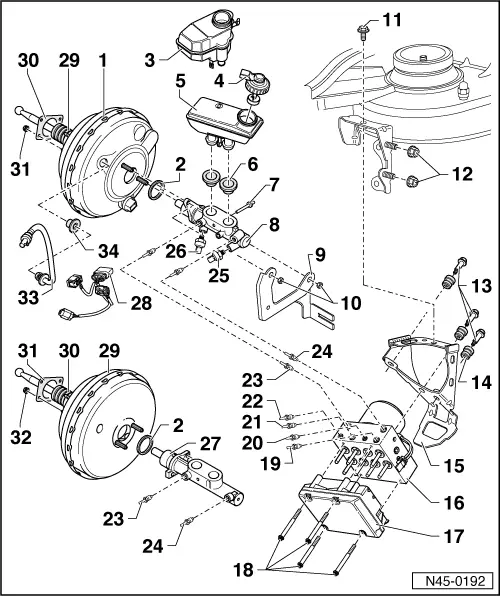

Leon Mk2

| Assembly overview - hydraulic unit, brake servo/brake master cylinder |

| 1 - | Brake servo |

| q | For vehicles with ABS/EDL/TCS/ESP only. |

| q | With wiring harness for brake pressure sender 1 -G201- → Item and brake pressure sender 2 -G214- → Item. |

| q | On petrol engines the vacuum required is taken from the intake manifold. |

| q | On Diesel engines an exhauster is installed to create the required vacuum. |

| q | Functional check: |

| – | With engine switched off, depress brake pedal firmly several times (to exhaust the vacuum in the unit). |

| – | Now depress brake pedal with average foot pressure, hold and start engine. If the servo unit is working properly, the pedal will be felt to give slightly under foot (servo assistance becomes effective). |

| q | If faulty renew complete. |

| q | Separating from brake pedal → Chapter. |

| q | Removing and installing → Chapter. |

| q | Non-return valve (in vacuum hose) → Chapter |

| q | Brake assistant system in the brake servo → Chapter |

| 2 - | Gasket |

| q | For brake servo. |

| 3 - | Brake fluid reservoir, right-hand drive |

| 4 - | Sealing cap with switch for brake fluid level |

| 5 - | Brake fluid reservoir, left-hand drive |

| 6 - | Sealing plug |

| q | Moisten with brake fluid and press into expansion tank |

| 7 - | Retainer pin |

| q | Insert through brake master cylinder |

| 8 - | Brake master cylinder |

| q | For vehicles with ABS/EDL/TCS/ESP only. |

| q | Cannot be repaired. If faulty, renew complete. |

| 9 - | Mounting plate |

| q | Used to secure the brake servo wiring harness |

| 10 - | Self-locking nut, 25 Nm |

| q | Renew each time after removing. |

| 11 - | Hexagon bolt, 20 Nm |

| 12 - | Hexagon nut, 20 Nm |

| 13 - | Fitted bolt, 8 Nm |

| 14 - | Rubber damper |

| 15 - | Bracket |

| 16 - | ABS hydraulic unit |

| 17 - | Control unit |

| q | Do not detach connector for control unit before self-diagnosis |

| 18 - | External Torx screw E 5, 4 Nm |

| 19 - | Brake pipe connection |

| q | Hydraulic unit to front left brake caliper. |

| 20 - | Brake pipe connection |

| q | Hydraulic unit to rear right brake caliper. |

| 21 - | Brake pipe connection |

| q | Hydraulic unit to rear left brake caliper. |

| 22 - | Brake pipe connection |

| q | Hydraulic unit to front right brake caliper. |

| 23 - | Brake pipe |

| q | Brake master cylinder/primary piston circuit to hydraulic unit. |

| 24 - | Brake pipe |

| q | Master brake cylinder/secondary piston circuit to hydraulic unit. |

| 25 - | Brake pressure sender 1 -G201--1- |

| q | 25 Nm |

| q | Removing and installing → Chapter. |

| 26 - | Brake pressure sender 2 -G214--2- |

| q | Not available in ABS Mark 25 |

| q | 25 Nm |

| q | Removing and installing → Chapter. |

| 27 - | Brake master cylinder |

| q | Vehicles without ABS/EDL/TCS/ESP |

| q | Cannot be repaired. If faulty, renew complete. |

| 28 - | Wiring harness |

| 29 - | Brake servo |

| q | Vehicles without ABS/EDL/TCS/ESP |

| q | On petrol engines the vacuum required is taken from the intake manifold. |

| q | On Diesel engines an exhauster is installed to create the required vacuum. |

| q | Functional check: |

| q | With engine switched off, depress brake pedal firmly several times (to exhaust the vacuum in the unit). |

| q | Now depress brake pedal with average foot pressure, hold and start engine. If the servo unit is working properly, the pedal will be felt to give slightly under foot (servo assistance becomes effective). |

| q | If faulty renew complete. |

| q | Separating from brake pedal → Chapter. |

| q | Removing and installing → Chapter. |

| q | Non-return valve (in vacuum hose) → Chapter |

| q | Brake assistant system in the brake servo → Chapter |

| 30 - | Bellows |

| q | Ensure it is seated correctly, danger of suction noises |

| 31 - | Gasket |

| q | For brake servo. |

| 32 - | Self-locking hexagon nut, 25 Nm |

| q | Renew each time after removing. |

| 33 - | Vacuum hose |

| q | Insert into brake servo unit. |

| 34 - | Sealing plug |