| –

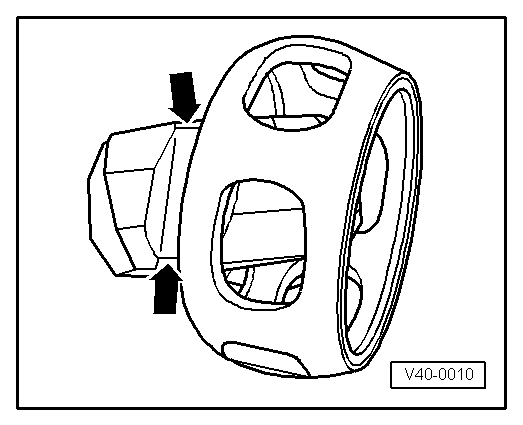

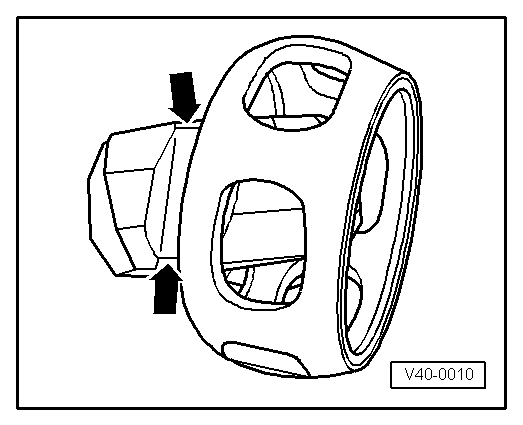

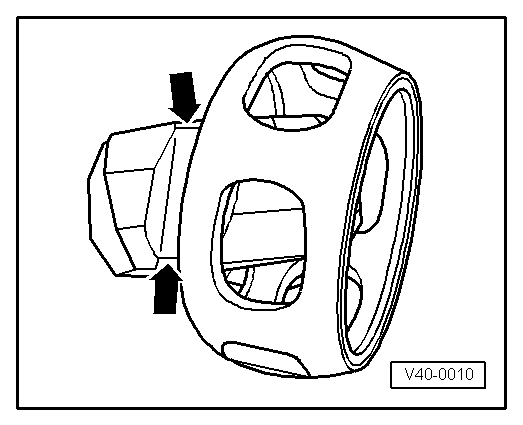

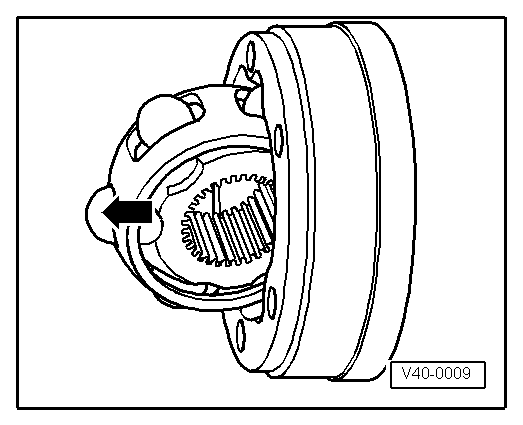

| Extract the ball hub, keeping them inclined, keeping the balls on their friction tracks -arrows- in the cage. |

| –

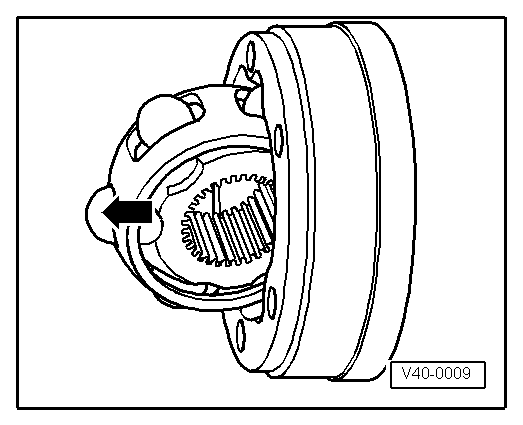

| Verify the joint element, the ball hub, the ball cage and the balls, searching for pitting and tracks. |

Note | Replace the joint if there is too much rotational play. This can be felt as knocks when the load is inverted. Even if the balls have smooth areas or tracks, there is no reason to change the joint. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note