Leon Mk2

Note

Note

|

|

|

|

| Tightening torques: | |

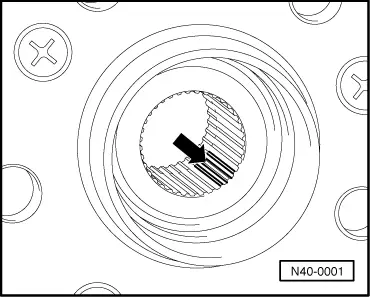

| CV joint to gearbox attachment. | 45 Nm |

| Tripod joint housing to gearbox | 40 Nm |

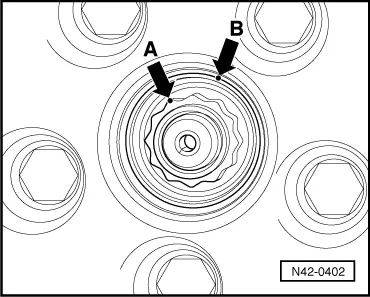

| Self-locking dodecagonal nut Use a new nut | 50 Nm + 1/8 turn (45º) |

| Attaching the wheel | 110 Nm |

Note

Note

|