Note | t

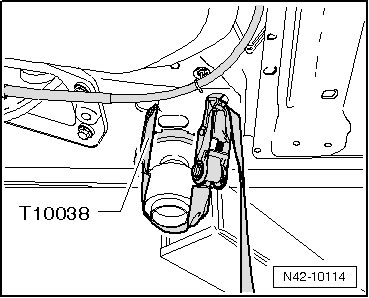

| Before beginning the removal of the subframe, ensure that the ignition key is not inserted in the ignition lock. |

| t

| For those vehicles fitted with xenon dual-function headlights, the connection on the vehicle level sender must be unplugged before beginning the removal of the strut; this is located on the front left hand side suspension → Electric system; Rep. gr. 94 . |

| t

| To verify the height off the ground, „the vehicle must be empty“, the fuel tank must be filled to at least 3/4 of its total capacity, the spare wheel must be in place along with the vehicle tools and jack. |

| t

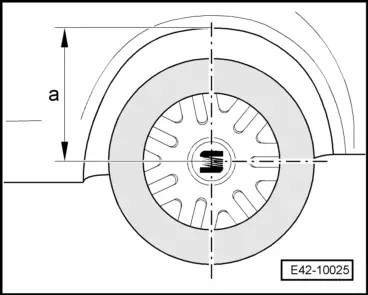

| With the clearance off the ground at the level -a-, tolerances remain well under the maximum torsion torque of the bonded rubber bush, thus preserving their working life. |

| t

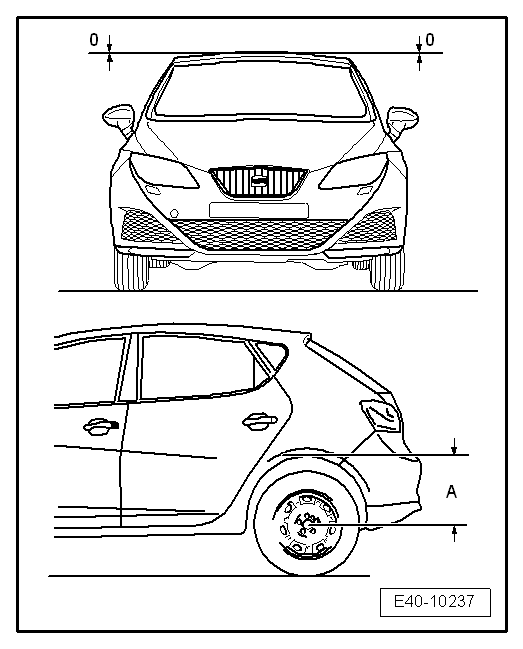

| The line 0 is parallel to the floor. Set the vehicle on a flat area. The measurement -0- → Fig. must be the same on both sides, so that unloaded vehicle height off the ground and steering geometry can be checked. |

| t

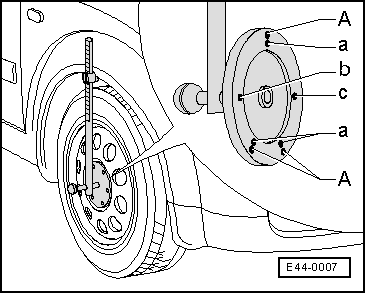

| The ground clearance must be checked before beginning the removal of the strut or of elements connected to the suspension. It is necessary to differentiate between new and already used wheel suspension, dimension-a-. |

| t

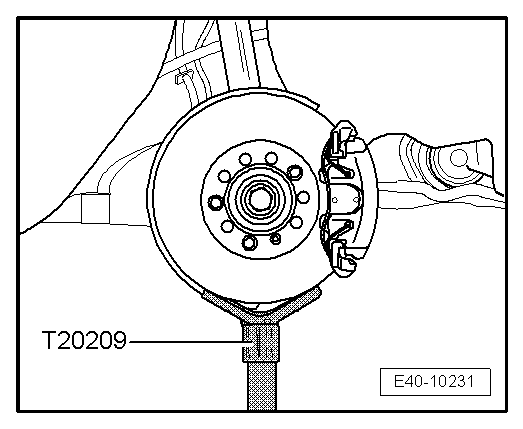

| Used wheel suspension → Fig. |

|

|

|

Note

Note

WARNING

WARNING