| –

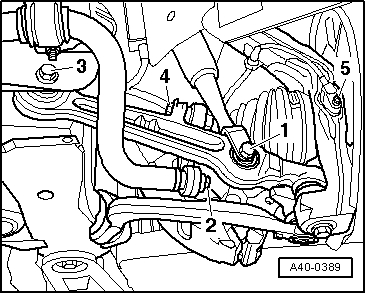

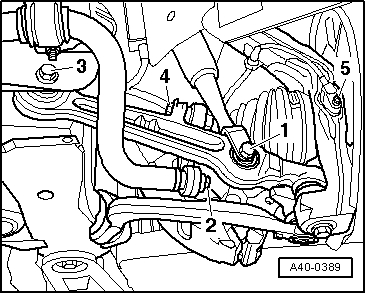

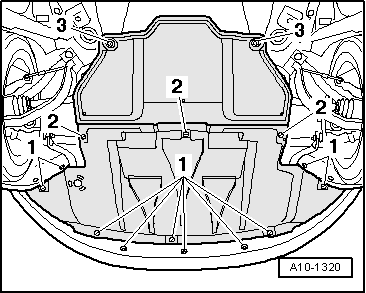

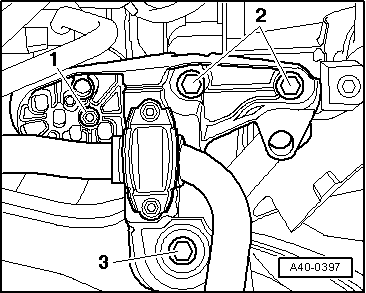

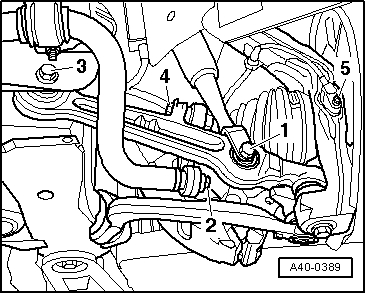

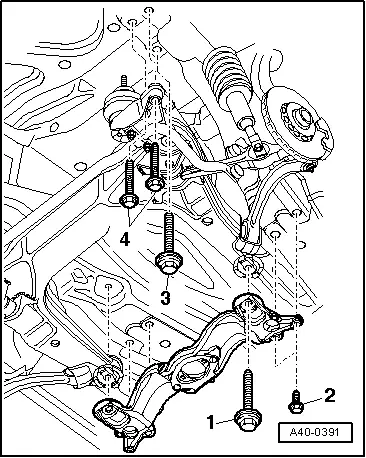

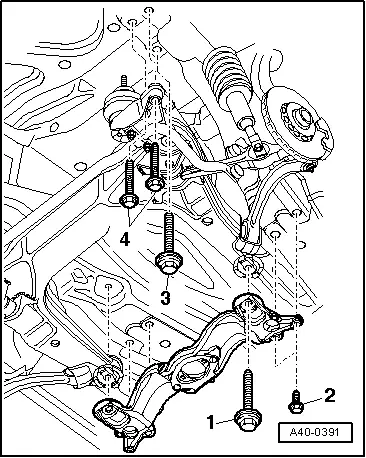

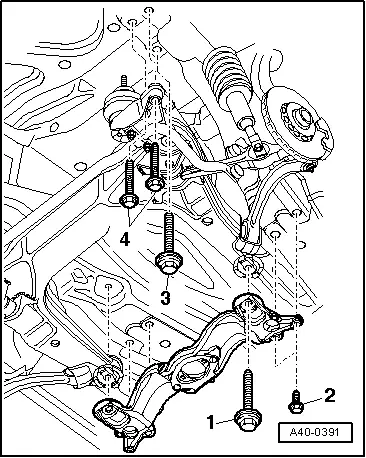

| Tighten the hexagon bolts -3- of the track control link to 70 Nm and continue for 180°. |

| –

| Tighten the hexagon bolts → Item of the track control link to 70 Nm and continue for 180°. |

| –

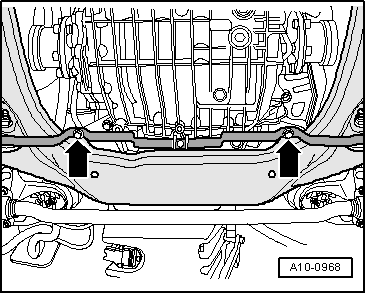

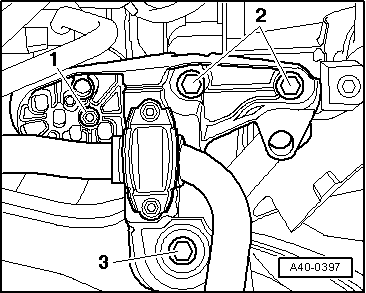

| Install the stabiliser bar and tighten the bolts with the appropriate torque → Chapter. |

Note | t

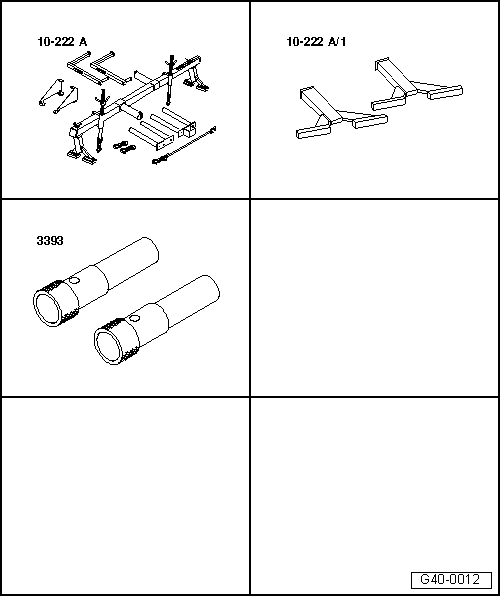

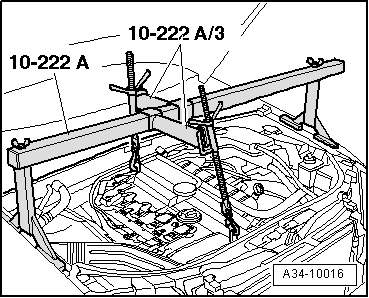

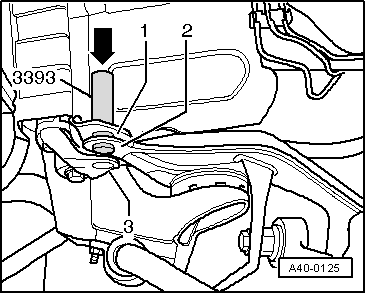

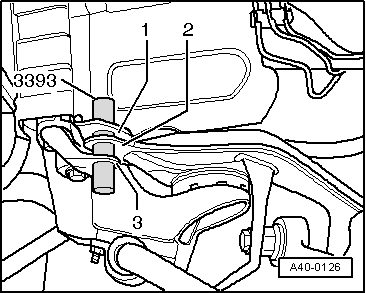

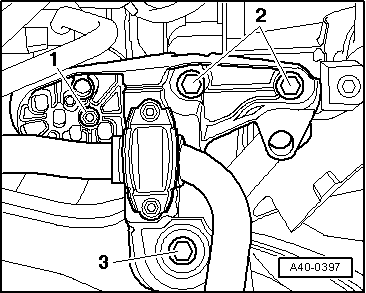

| If attachment to the bodywork was made with the test mandrels -3393- before the assembly of the sub-frame (before final tightening of the bolts), the wheel axle alignment can be dispensed with. |

| t

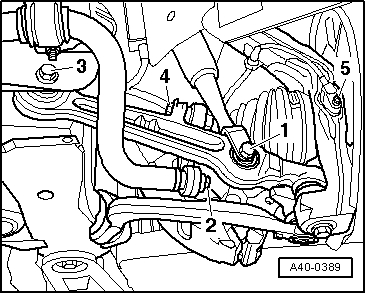

| If such a fixing has not been done, axle alignment is necessary. |

| –

| If necessary, perform an → Chapteraxle alignment. |

| Setting of the running gear must be done with an alignment stand recommended by SEAT. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note