Leon Mk2

| Subframe: Assembly overview |

Caution

Caution

|

| 1 - | Sub-frame |

| q | Securing → Chapter |

| q | Lowering → Chapter |

| q | Removing and installing without steering box → Chapter |

| q | Removing and installing with steering box → Chapter |

| q | Different versions available |

| q | Assignment → Electronic parts catalogue „ETKA“ |

| 2 - | Adapter |

| 3 - | Mounting bracket |

| q | Securing → Fig. |

| q | With bonded rubber bush |

| 4 - | Bolt. |

| q | M10 x 70 |

| q | 50 Nm and then turn 90° further |

| q | Always renew if removed |

| 5 - | Front left vehicle level sender -G78- |

| q | removing and installing → Chapter |

| q | Can be tested in guided fault finding using → Vehicle diagnostic tester |

| 6 - | Bolt. |

| q | 9 Nm |

| 7 - | Bolt. |

| q | M12 x 1.5 x 100: 70 Nm and then turn 180° further |

| q | Always renew if removed |

| 8 - | Wishbone |

| q | If damaged, also renew swivel joint |

| q | removing and installing → Chapter |

| q | Renew mounting → Chapter |

| q | Different versions of suspension links are possible (cast steel, sheet steel, aluminium). |

| q | Assignment → Electronic parts catalogue „ETKA“ |

Note

Note| A mixed installation of suspension links of different types or made of different materials is not permissible. |

| 9 - | Nut |

| q | 9 Nm |

| 10 - | Bolt. |

| q | M12 x 1.5 x 90 |

| q | 70 Nm and then turn 180° further |

| q | Always renew if removed |

| 11 - | Bolt. |

| q | M14 x 1.5 x 70 |

| q | 100 Nm and then turn 90° further |

| q | Do not tighten until pendulum support is bolted to gearbox |

| q | Always renew if removed |

| 12 - | Bolt. |

| q | M10 x 75: 50 Nm and then turn 90° further |

| q | M12 x 1.5 x 85: 60 Nm and then turn 90° further |

| q | Always renew if removed |

| 13 - | Bolt. |

| q | M10 x 35: 50 Nm and then turn 90° further |

| q | M12 x 1.5 x 50: 60 Nm and then turn 90° further |

| q | Always renew if removed |

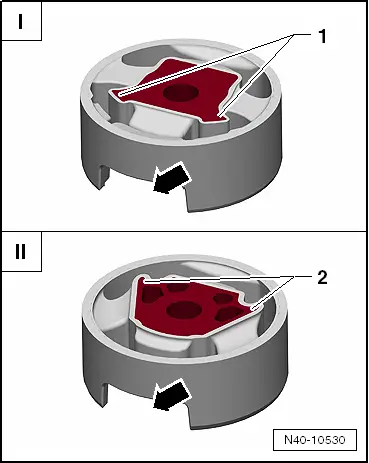

| 14 - | Lower bonded rubber bush for pendulum support |

| q | Pressing off and driving in → Chapter |

| q | Different versions → Fig. |

| 15 - | Pendulum support |

| q | Bolt to gearbox first, then to subframe |

| q | Different versions available |

| q | Assignment → Electronic parts catalogue „ETKA“ |

| 16 - | Upper bonder rubber bush for pendulum support |

| q | Pressing off and driving in → Chapter |

| q | Different versions → Fig. |

| 17 - | Bolt. |

| q | M12 x 1.5 x 110 |

| q | 70 Nm and then turn 180° further |

| q | Always renew if removed |

| q | Tighten only when the vehicle is in unladen weight position. → Chapter |

| 18 - | Bolt. |

| q | M12 x 1.5 x 100 |

| q | 70 Nm and then turn 180° further |

| q | Always renew if removed |

Note

Note

|

|