| –

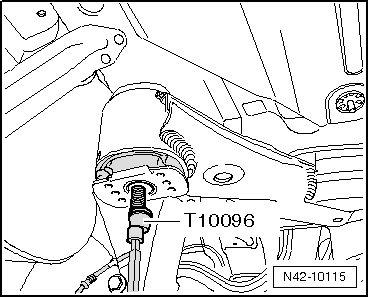

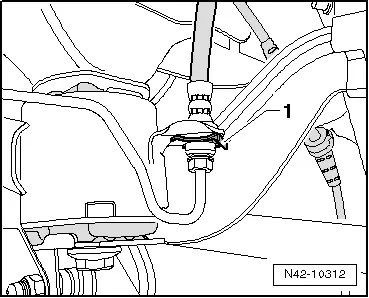

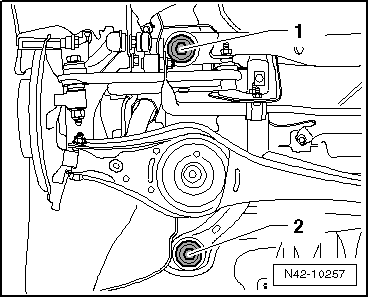

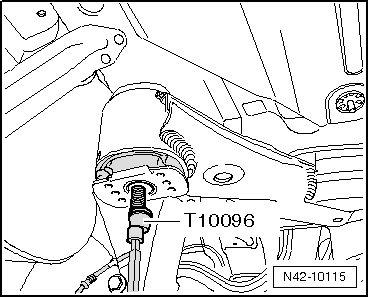

| Secure position of subframe with locating pins -T10096-. |

Note | The locating pins -T10096- must not be tightened to more than 20 Nm, otherwise the threads of the locating pins will be damaged. |

| –

| Replace securing bolts on subframe with locating pins -T10096- one after the other on both sides of the vehicle and tighten to 20 Nm. |

| The position of the subframe is now fixed. |

| –

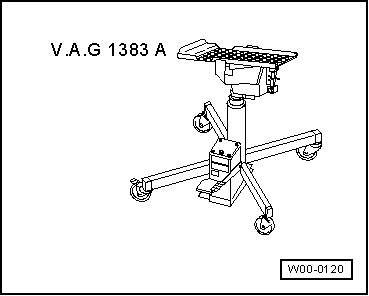

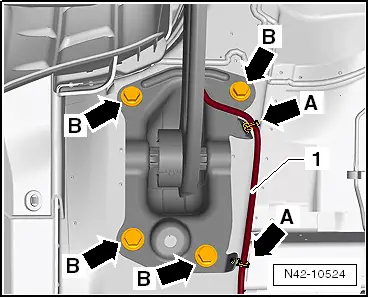

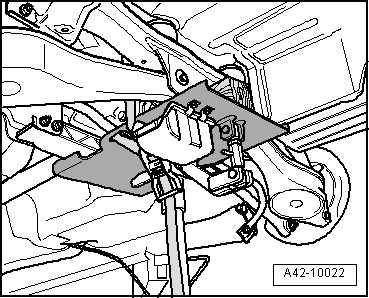

| Carefully lower subframe with attachments. |

Note | When lowering, ensure sufficient clearance to brake lines and electrical wiring. |

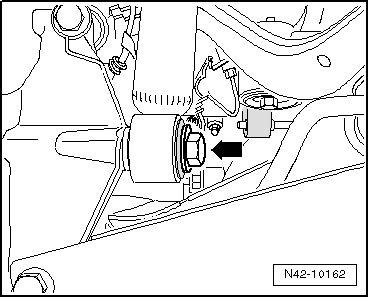

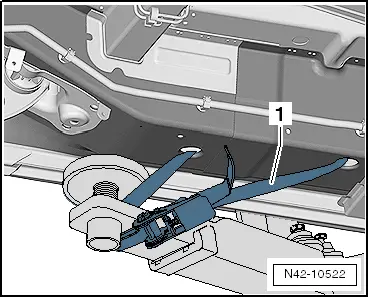

| Installing subframe with attachments |

| Installation is carried out in reverse order. In the process, note the following: |

| –

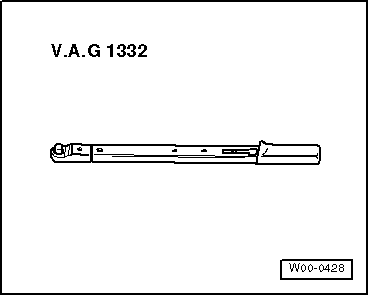

| Mount the wheels, tightening torque. |

|

|

|

Note

Note

Note

Note Note

Note

WARNING

WARNING