Leon Mk2

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Specified torques |

| Component | Tightening torque | ||||||||

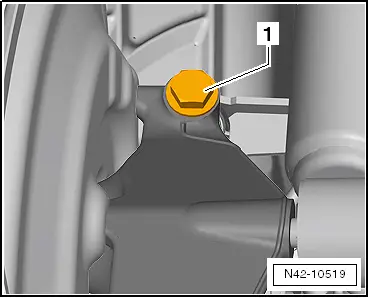

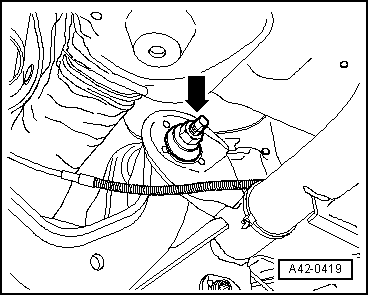

Upper transverse link to wheel bearing housing

| 130 Nm + 90° | ||||||||

Upper transverse link to subframe

| 95 Nm

|