| Tighten the clamp of the inner joint |

| –

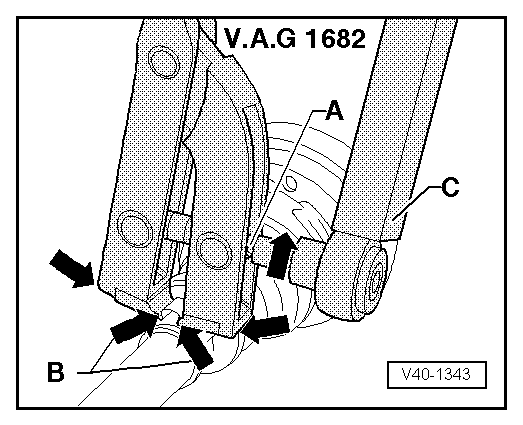

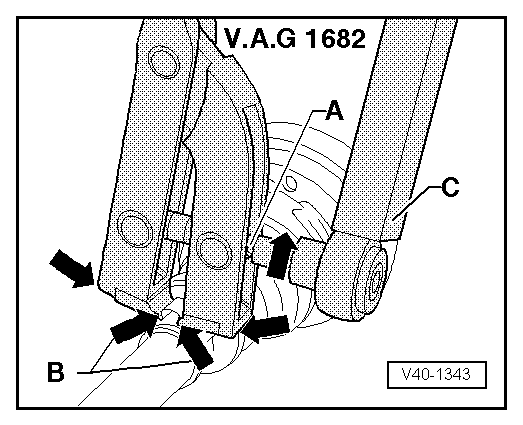

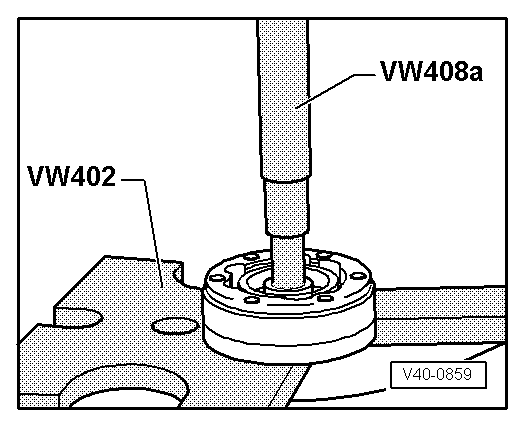

| To do so, position the pliers -V.A.G 1682- as shown in the figure. Ensure that the edges of the tool fit into the corners -arrows B- of the clamp. |

| –

| Tense the clamp by turning the spindle using the torque wrench taking special care not to incline the pliers during the operation. |

Note | t

| Given the firmness of the material (in comparison with the rubber) of the union dust guard, a stainless steel clamp is required, this can only be tightened using the pliers -V.A.G 1682-. |

| t

| Tightening torque: 20 Nm |

| t

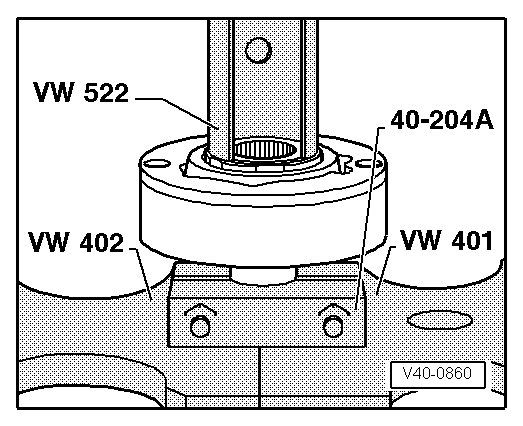

| Use a torque wrench-C- with a range between 5 and 50 Nm (e.g. -V.A.G 1331-). |

| t

| Check that the spindle thread -A- of the pliers can be tightened without forcing. Apply grease -MOS 2-, if necessary. |

| t

| If the thread does not turn easily (due to dirt, for example), it will not be possible to tighten the clamp sufficiently when applying the specified torque. |

|

|

|

Note

Note

Note

Note