| –

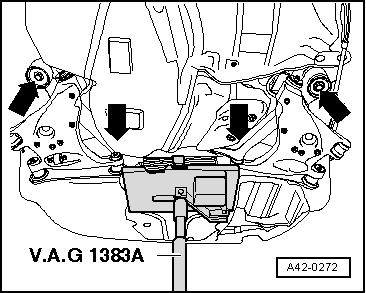

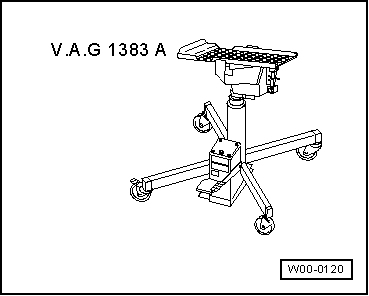

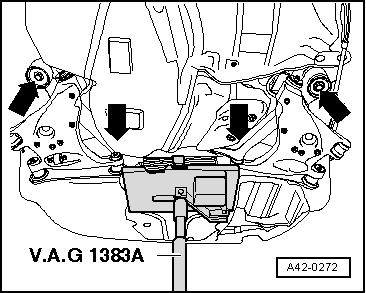

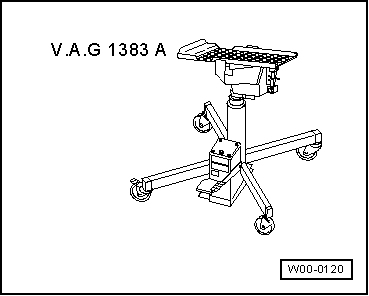

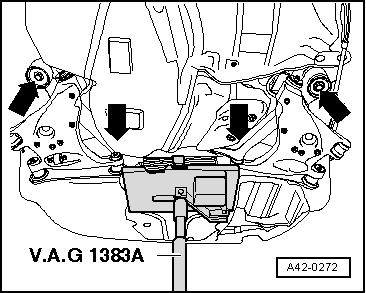

| Position engine and gearbox lifter -V.A.G 1383 A- on subframe with suitable wooden insert. |

| –

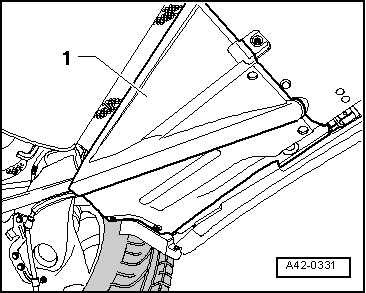

| Tension tensioning belt -T10038- around subframe. |

Note | t

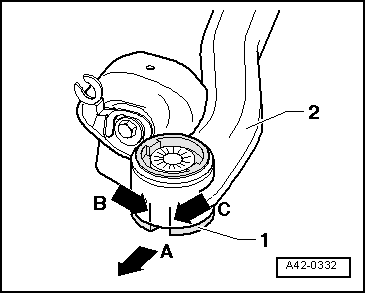

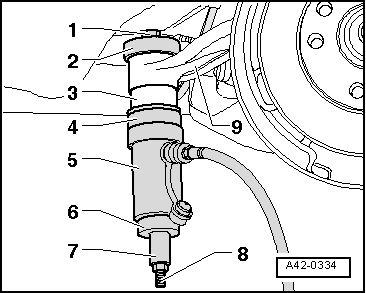

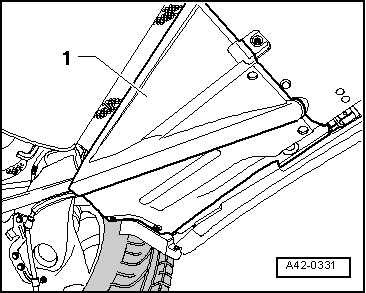

| If a front bonded rubber bush needs to be replaced, loosen only the front bolts of the subframe. |

| t

| If a rear bonded rubber bush needs to be replaced, loosen only the rear bolts of the subframe. |

| t

| If a further subframe bolt is loosened (front or rear), wheel alignment must be performed following installation. |

| –

| Loosen the front or rear bolts behind the subframe. |

| –

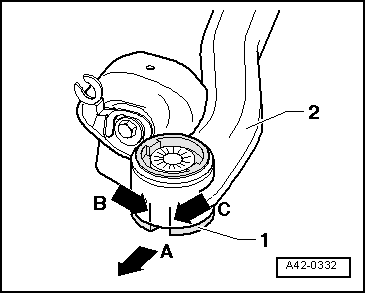

| Carefully lower the subframe to about 5 cm. |

| –

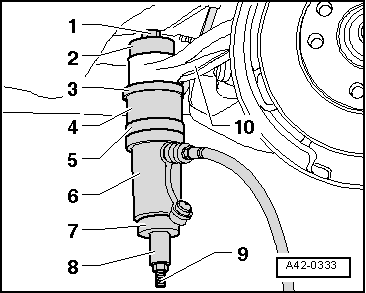

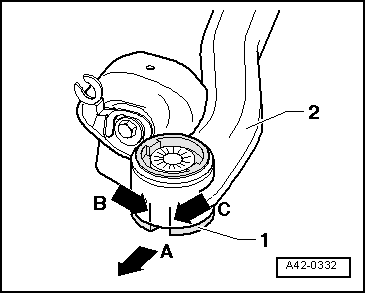

| Pull out only such bolts from the subframe, where the bonded rubber bush needs to be replaced. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note