Leon Mk2

|

| -Arrow- indicates direction of travel. |

| 1 - | Mounting bracket |

| 2 - | Cover |

| 3 - | Bolt. |

| q | M12 x 1.5 x 80 |

| q | 90 Nm and then turn 90° further |

| q | Always renew if removed |

| 4 - | Coupling rod |

| q | Connects anti-roll bar to trailing arm/wheel bearing housing |

| 5 - | Bolt. |

| q | 90 Nm and then turn 45° further |

| q | Observe tightening sequence → Fig. |

| q | Always renew if removed |

| 6 - | Trailing arm |

| q | removing and installing → Chapter |

| q | Repairs → Chapter |

| 7 - | Drive shaft |

| q | Assembly overview → Chapter |

| q | removing and installing → Chapter |

| 8 - | Multi-point socket head bolt |

| q | M14 x 1.5 x 45 |

| q | 70 Nm and then turn 90° further |

| q | Always renew if removed |

| 9 - | Wheel bearing housing |

| q | removing and installing → Chapter |

| q | Installing with wheel bearing housings made from cast steel is permissible → Electronic parts catalogue „ETKA“ |

| q | Only wheel bearing housings made from aluminium are available as replacement parts. Therefore, certain parts have to be exchanged and/or installed in addition when replacing → Chapter |

| 10 - | Rear right speed sensor -G44-/rear left speed sensor -G46- |

| q | Can be checked in guided fault finding of the vehicle diagnosis, testing and information system -VAS 5051- |

| q | Before inserting sensor, clean inner surface of bore and coat with lubricating paste -G 000 650- |

| 11 - | Hexagon socket head bolt |

| q | M6 x 16 |

| q | 8 Nm |

| 12 - | Bonded rubber bush |

| q | replace → Chapter |

| 13 - | Nut |

| q | M12 x 25 |

| q | 45 Nm |

| q | Self-locking |

| q | Always renew if removed |

| 14 - | Bolt. |

| q | M10 x 35 |

| q | 50 Nm and then turn 45° further |

| q | Always renew if removed |

| 15 - | Bolt. |

| q | 4 Nm |

| 16 - | Brake disc |

| 17 - | Bolt. |

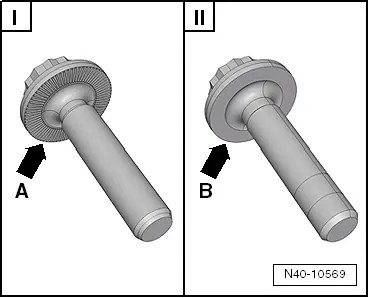

| q | Different versions available |

| q | Assignment → Electronic parts catalogue „ETKA“ |

| q | Hexagon bolt = 180 Nm + 180° further |

| q | Loosening and tightening hexagon bolt for drive shaft → Chapter |

WARNING

WARNING

|

| q | Always renew if removed |

| 18 - | Wheel hub with wheel bearing |

| q | The ABS sensor ring is installed in the wheel bearing |

| q | removing and installing → Chapter |

| The wheel bearing and wheel hub are assembled in one housing. |

| This wheel bearing/hub unit is maintenance-free and has zero play. Adjusting and repair work is therefore not possible! |

| 19 - | Bolt. |

| q | M6 x 12 |

| q | 12 Nm |

| 20 - | Cover plate |