| –

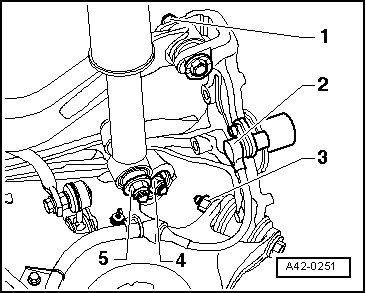

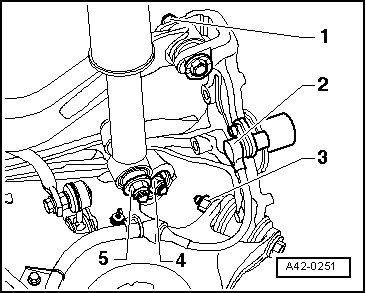

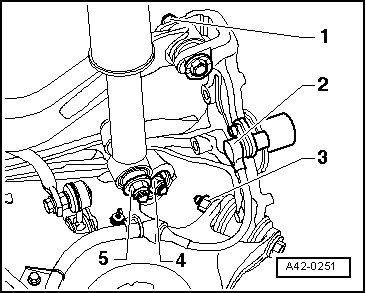

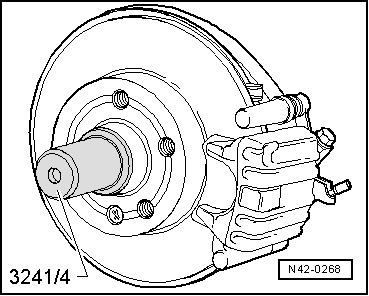

| Unbolt speed sensor -2-. |

| –

| Mark position of eccentric bolt -1- at top of wheel bearing housing. |

| –

| Detach the illustrated bolt connections in the following sequence: Item 5, Item 3, Item 4, Item 1. |

| –

| Take out wheel bearing housing. |

| Installation is carried out in the reverse sequence; note the following: |

Note | t

| Replace bolts and self-locking nuts ⇒ instructions in the exploded view from page → Chapter. |

| t

| Bonded rubber bushes can only be turned to a limited extent. The mountings of the suspension links must therefore only be tightened when the suspension is in the unladen position → Chapter. |

| –

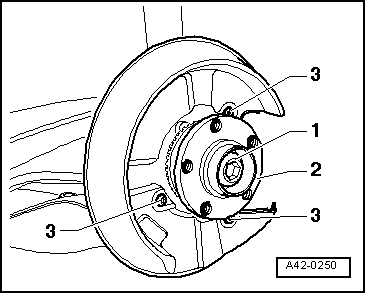

| If required, install new wheel bearing and wheel hub unit ⇒ See note on page → Anchor. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING