| –

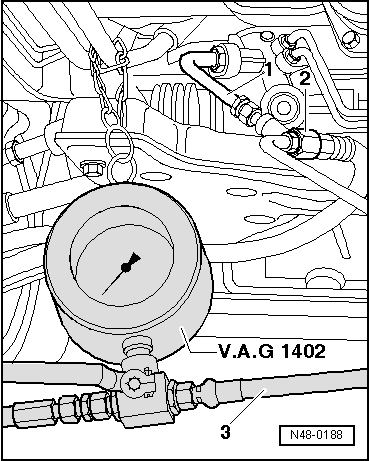

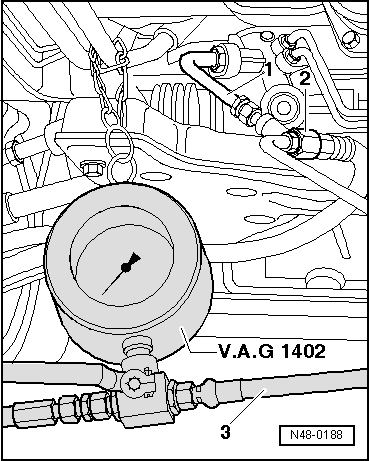

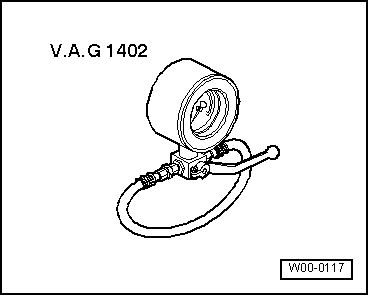

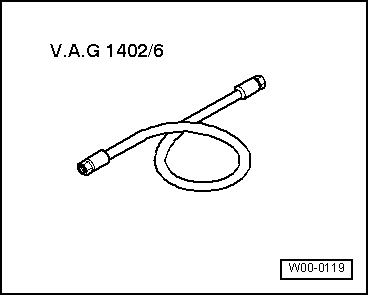

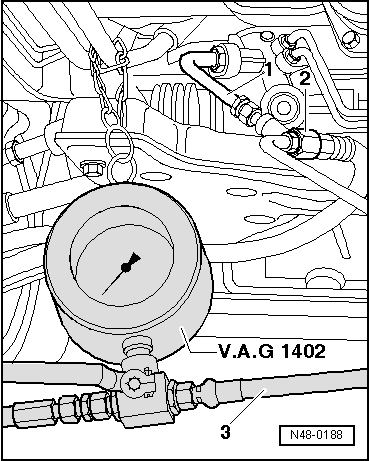

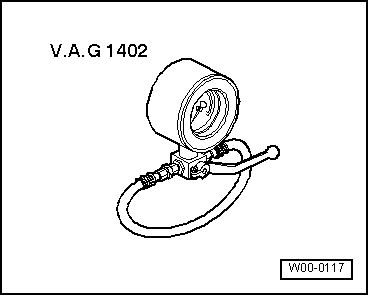

| Connect the manometer -V.A.G 1402- as shown in the figure. Open the shut-off valve on the manometer. |

| –

| Top up the hydraulic oil -G 002 000-. |

| –

| Start the engine and, if necessary, add more oil to the reservoir. Check that the hose connections do not leak. |

| –

| Close the shut-off valve when the engine is idling (not more than 5 seconds), and read the pressure. |

| –

| Specified value: 100 … 110 bar pressure |

Note | t

| Replace the pump if the actual value is 5 bar over or below the specified value. |

| t

| Assembly overview of vane pump for vehicles with 4-cylinder engines → Chapter. |

| t

| Assembly overview of vane pump for vehicles with 6-cylinder engines → Chapter |

| t

| If the steering knuckle pinion leaks, then the pipes and connections must be checked and, if necessary, retightened and cleaned until dry. |

| t

| Replace the steering box if there are leaks in the steering pinion seal or in the sealing element of the rack, in the steering box. To check for leaks in the rack, the dust guard must be moved aside. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note