Leon Mk2

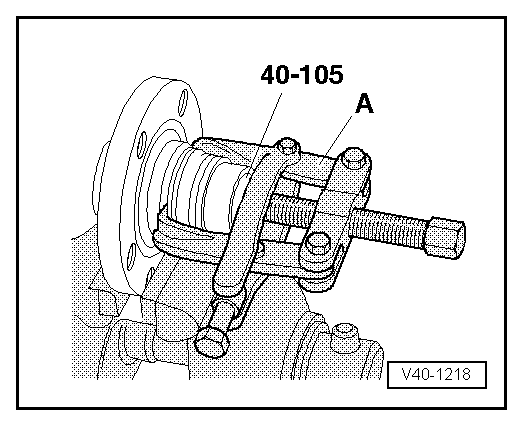

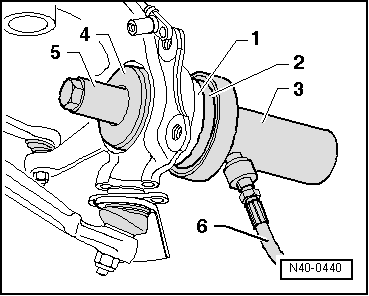

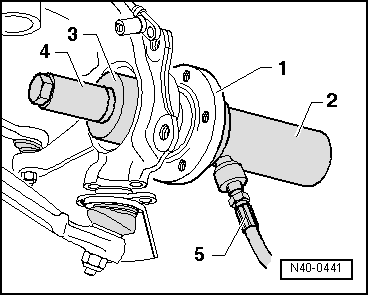

| Pressing front wheel bearing out and in with wheel bearing housing installed |

| Special tools and workshop equipment required |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383 A- with universal gearbox support -V.A.G 1359/2- |

| t | Thrust piece -VAS 6016- |

| t | -3-Puller -Kukko 204/2- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Bolt | Specified torque | ||

| Swivel joint to wheel bearing housing | 55 Nm | ||

Drive shaft to hub

| 150 Nm + 90° further | ||

| Brake carrier to wheel bearing housing | → Rep. Gr.46 | ||

| Wheel bolts to wheel hub | → Chapter |