| Tensioning hose clamp on inner joint |

| –

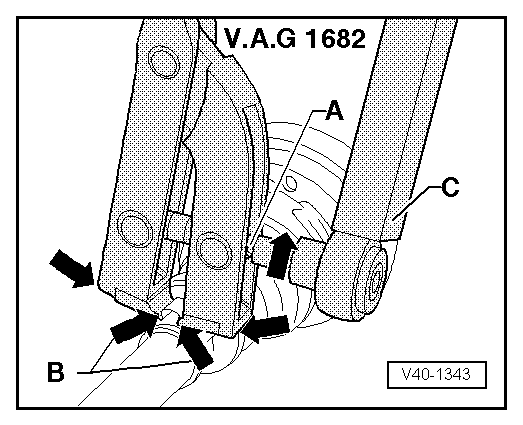

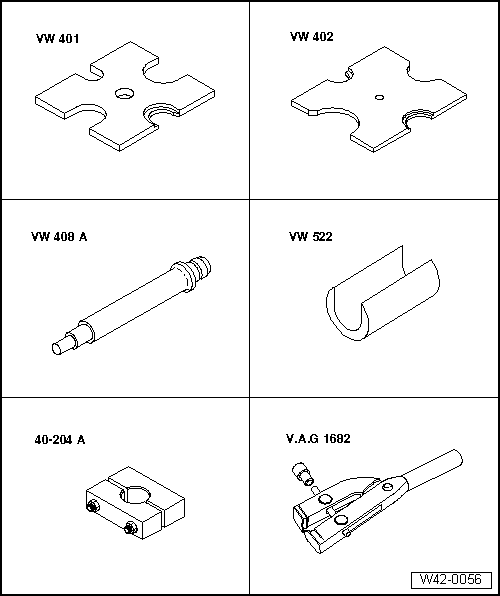

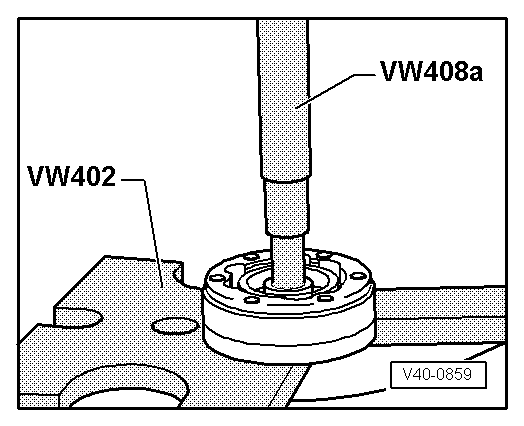

| Position pliers -V.A.G 1682- as shown in diagram. Thereby ensure that the jaws of the pliers seat in the corners -arrow B- of the hose clamp. |

| –

| Tension hose clip by turning the spindle with a torque wrench (do not cant pliers). |

Note | t

| Due to the hard material of the protective boot (compared to rubber) and, due to the use of a stainless steel clip, it is only possible to tension the clip using pliers -V.A.G 1682-. |

| t

| Specified torque: 20 Nm. |

| t

| Use torque wrench-C- with 5...50 Nm range (e.g. -V.A.G 1331-). |

| t

| Ensure that the spindle thread -A- is not tight. If necessary lubricate with grease -MOS 2-. |

| t

| If the thread is tight (e.g. due to dirt), the required clamping force for the boot clamp will not be attained although the correct torque is applied. |

|

|

|

Note

Note

Note

Note