| –

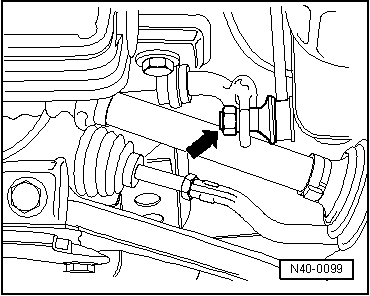

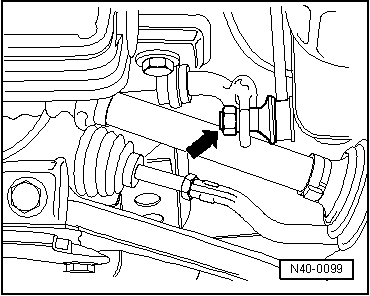

| Remove coupling rod from anti-roll bar -arrow-. |

| –

| Position engine/gearbox jack -V.A.G 1383 A- under subframe. |

| –

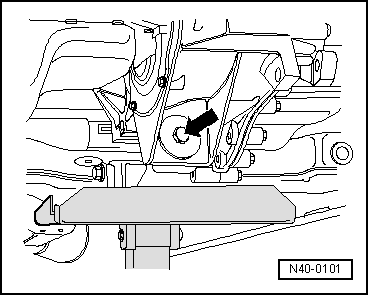

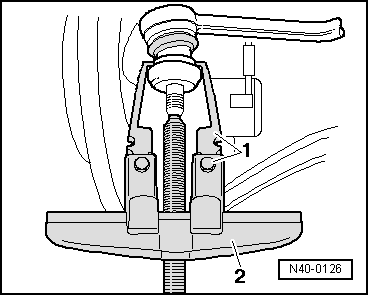

| Unbolt power assisted steering box from subframe. |

| –

| Remove bolts for assembly carrier. |

| –

| Lower subframe with engine and gearbox jack -V.A.G 1383 A-. |

| –

| Disconnect hoses from steering box (if not yet disconnected) and seal with plastic bag and adhesive tape. Seal threaded holes on power assisted steering box with plastic plugs. |

| –

| Take power assisted steering box out to rear. |

Note | t

| Use new sealing rings for hose/line connections. |

| t

| Moisten steering box seals with lubricant, e.g. soft soap, before installing steering box. |

| t

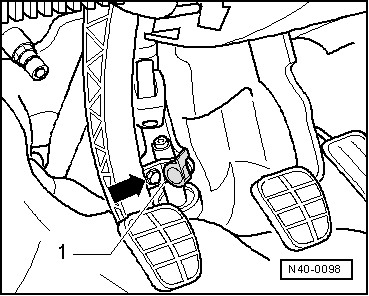

| After fitting the steering box, ensure that the seal lies against the base plate without kinking and that the opening to the footwell is correctly sealed. Water ingress and/or noises may be the result. |

| t

| Ensure sealing surfaces are clean. |

| Observe oil level in reservoir, after filling with hydraulic oil and starting engine. The oil level must sink. |

| If this is not the case, stop engine, unscrew pressure pipe at P.A.S. box and wait until hydraulic oil discharges. |

| –

| Attach pipe again and start engine, top-up oil level. |

| –

| Check front wheel alignment and position of steering wheel. |

|

|

|

Note

Note