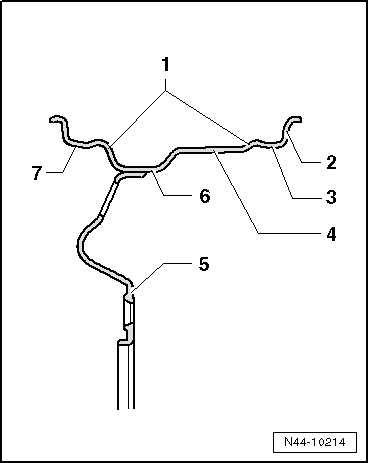

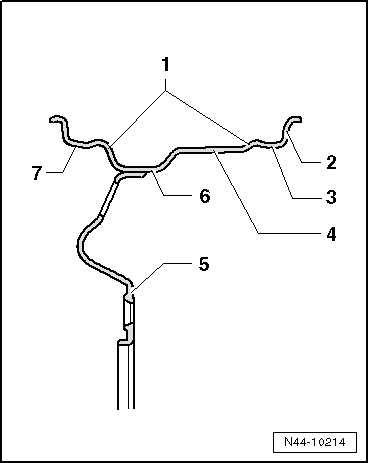

| Modern radial vehicle tyres are exclusively fitted on safety rims, these have a perimeter ridge on the shoulders -1-. |

| 1 - | Hump (double hump H 2, high double hump EH2) |

| 3 - | Interior shoulder of wheel rim (for example, oblique shoulder rims) |

| 7 - | Exterior shoulder of wheel rim (for example, oblique shoulder rims) |

| This ridge prevents the tyre bead from being flattened by the wheel rim shoulders when driving with underinflated tyres. |

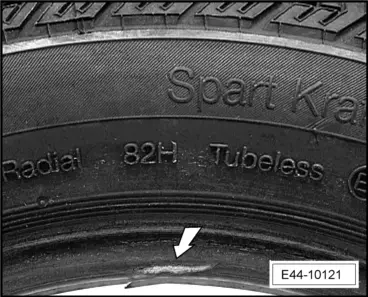

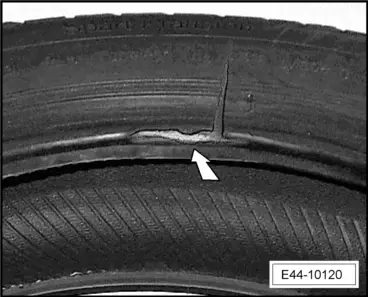

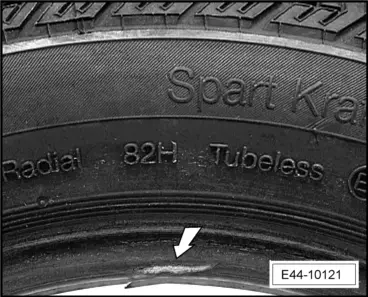

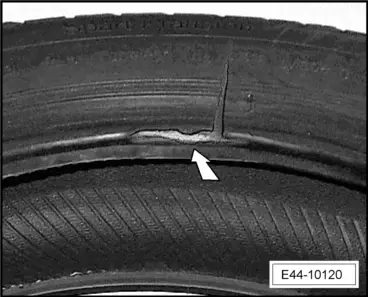

| When the tyre is inflated, the bead may be caught on the narrow shoulder rim, on the ridge, on part of the perimeter. |

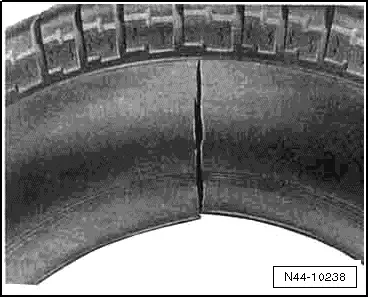

| In this case, there is a risk of forcing the tyre bead in the event of overinflation, and breaking the steel cables either partially or totally. Generally, breaks in the bead can not be perceived from the exterior. |

| Special features on tyres with emergency running characteristics |

| Tyres with emergency running characteristics (reinforced side walls) require rims with extended double hump (extended double hump EH2) → Chapter. The extended double hump prevents the deflated tyre from separating from the rim when flat. |

Note

WARNING | t

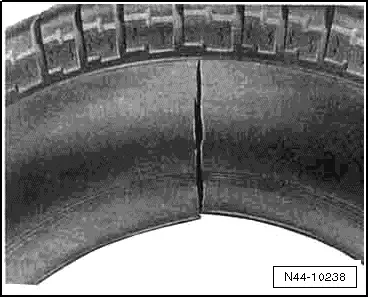

| Tyres with damaged bead do not fit safely onto the wheel rim. These tyres are dangerous. |

| t

| There is also a risk that the broken bead will be detached if the vehicle continues to be driven, and the tyre may break suddenly. If there is a break in the bead when the tyre is inflated during assembly, this will also destroy the tyre carcass. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note