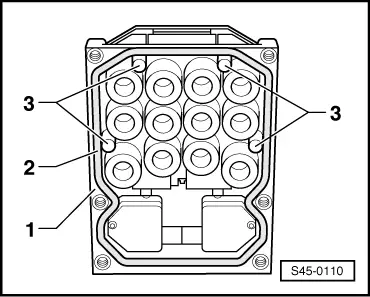

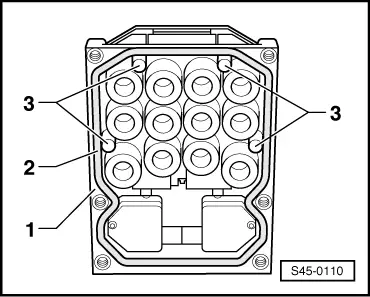

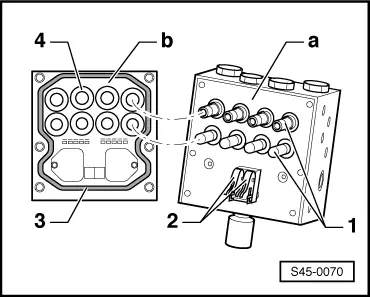

| If new or removed control units -1- are installed again, inspect the heat conduction posts -3-. |

| –

| Inspect the end faces of the heat conduction posts for good heat conduction properties. The faces must not exhibit any deposit, e.g. oxidation. |

| –

| Check projection of the posts using a gauge. |

|

| Dimension must be of 0.8...1.0 mm between the top side of the heat conduction posts and the seal -2-. |

| –

| Press the end face of the heat conduction posts with your thumb, they must give. |

| If faults are found during one of the 3 test steps, the control unit must be replaced. |

| Continued for all vehicles |

| –

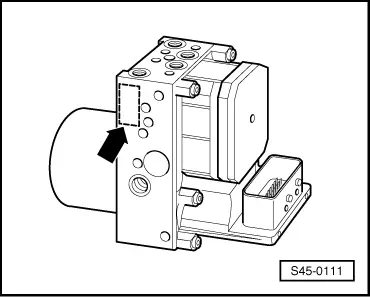

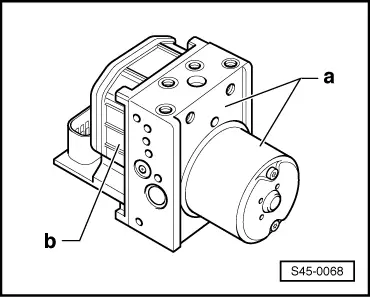

| Inspect the sealing surface on the hydraulic unit for soiling, if necessary clean with white spirits and a non-fluffing paper or linen cloth. |

| –

| If an oily or aqueous film appears on the surface of the hydraulic unit, clean with white spirits and a non-fluffing paper or linen cloth. |

| –

| If there is a considerable oily and aqueous film between the valves use moisture-free and oil-free compressed air to blow it out. |

| –

| If damage is noticed on the hydraulic unit (e.g. scoring or scratching etc.) near the seal, replace the hydraulic unit. |

| –

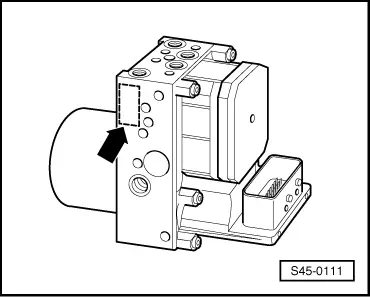

| Inspect the contact springs of the hydraulic pump for burning points and oxidation. Reworking or cleaning is not possible, replace the hydraulic unit. |

Note | t

| Before fitting the control unit to the hydraulic unit make sure the seal protrudes by min. 0.1 mm from the control unit housing. |

| t

| When assembling the control unit and the hydraulic unit make sure the valve domes of the hydraulic unit do not tilt along with the solenoid coils of the control unit. |

| –

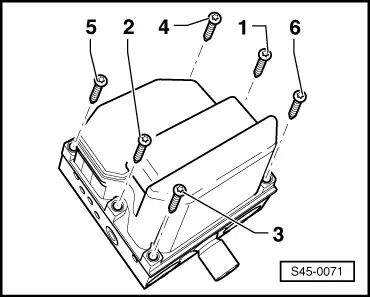

| Place the control unit on the hydraulic unit and guide the solenoid coils over the valves by exerting a slight pressure. While doing so center the control unit relatively to the hydraulic unit. The edge of the control unit must engage in the groove of the hydraulic unit. |

| –

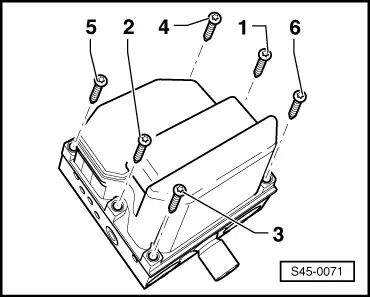

| Press by hand on the control unit until it fixes in place with the two centre screws. |

Note | t

| Screw on the hydraulic unit and the control unit in the prescribed sequence and in steps. Tightness will not be guaranteed if this is not observed. |

| t

| Only use new inner Torx screws from the parts kit. |

| t

| When screwing together make sure the left and right gap between the control unit and the hydraulic unit is always the same. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note