Fabia Mk1

Note

Note

|

| 1 - | Top toothed belt guard |

| 2 - | Toothed belt |

| q | before removing mark running direction |

| q | check for wear |

| q | do not kink |

| q | removing and installing → Chapter |

Note

Note| If the toothed belt is replaced when carrying out engine repair (apart from regular change interval), it should be entered in the Service Schedule! |

| 3 - | 20 Nm + torque a further 45° (1/8 turn) |

| 4 - | Tensioning pulley |

| 5 - | 100 Nm |

| 6 - | 20 Nm + torque a further 45° (1/8 turn) |

| 7 - | Camshaft sprocket |

| 8 - | Hub |

| q | with rotor |

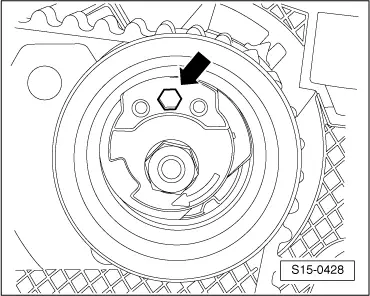

| q | to release and tighten use counterholder -T10051 - |

| q | to remove use extractor -T10052- |

| q | removing and installing → Chapter |

| 9 - | 10 Nm |

| 10 - | Rear toothed belt guard |

| 11 - | Grommet |

| q | replace if damaged |

| 12 - | Tensioning device for timing belt |

| 13 - | Guide pulley |

| 14 - | Coolant pump |

| q | removing and installing → Chapter |

| 15 - | Crankshaft timing belt sprocket |

| q | Contact surface between crankshaft timing belt sprocket and crankshaft must be clean and free of grease |

| q | Fitting position: flats on timing belt sprocket and crankshaft must be aligned |

| 16 - | 120 Nm + torque a further 90° (1/4 turn) |

| q | to release and tighten use counterholder -MP 1-310- or -T30004- |

| q | replace |

| q | do not wet new screws with oil and do not grease them |

| 17 - | 15 Nm |

| 18 - | 20 Nm |

| 19 - | Bottom toothed belt guard |

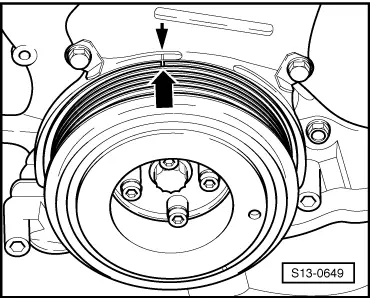

| 20 - | V-ribbed belt pulley |

| q | with vibration damper |

| q | Assembly only possible in one position - holes offset |

| 21 - | 10 Nm + torque a further 90° (1/4 turn) |

| 22 - | Middle toothed belt guard |

| 23 - | 45 Nm |

| 24 - | Engine mounting |

|

| 1 - | Top toothed belt guard |

| 2 - | Toothed belt |

| q | before removing mark running direction |

| q | check for wear |

| q | do not kink |

| q | removing and installing → Chapter |

Note

Note| If the toothed belt is replaced when carrying out engine repair (apart from regular change interval), it should be entered in the Service Schedule! |

| 3 - | 20 Nm + torque a further 45° (1/8 turn) |

| 4 - | Tensioning pulley → Fig. |

| 5 - | 20 Nm + torque a further 45° (1/8 turn) |

| 6 - | Camshaft sprocket |

| 7 - | 100 Nm |

| 8 - | Hub |

| q | with rotor |

| q | to release and tighten use counterholder -T10051- |

| q | to remove use extractor -T10052- |

| q | removing and installing → Chapter |

| 9 - | 10 Nm |

| 10 - | Rear toothed belt guard |

| 11 - | Grommet |

| q | replace if damaged |

| 12 - | O-ring |

| q | replace |

| 13 - | Coolant pump |

| q | removing and installing → Chapter |

| 14 - | 15 Nm |

| 15 - | Guide pulley |

| 16 - | Crankshaft timing belt sprocket |

| q | Contact surface between crankshaft timing belt sprocket and crankshaft must be clean and free of grease |

| q | Fitting position: flats on timing belt sprocket and crankshaft must be aligned |

| 17 - | 120 Nm + torque a further 90° (1/4 turn) |

| q | to release and tighten use counterholder -MP 1-310- or -T30004- |

| q | replace |

| q | do not wet new screws with oil and do not grease them |

| 18 - | 20 Nm + torque a further 45° (1/8 turn) |

| 19 - | Bottom toothed belt guard |

| 20 - | V-ribbed belt pulley → Fig. |

| q | with vibration damper |

| q | Assembly only possible in one position - holes offset |

| 21 - | 10 Nm + torque a further 90° (1/4 turn) |

| 22 - | Middle toothed belt guard |

| 23 - | 45 Nm |

| 24 - | Engine mounting |

|

|