| –

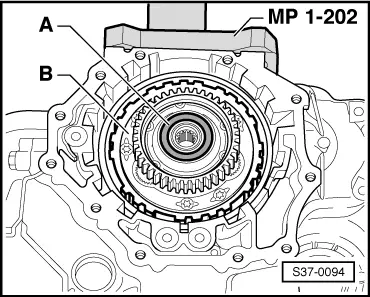

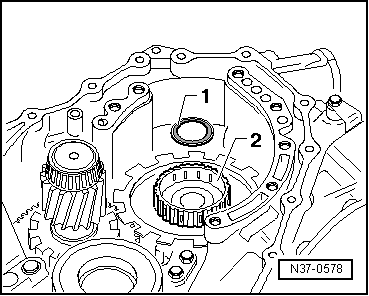

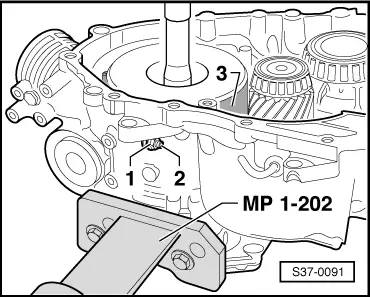

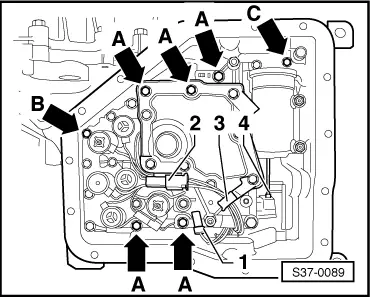

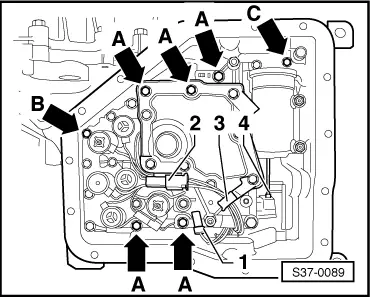

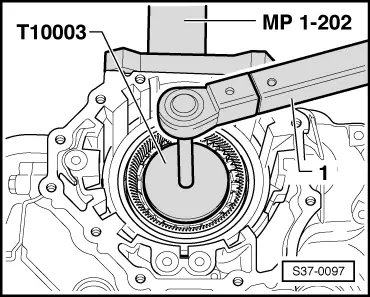

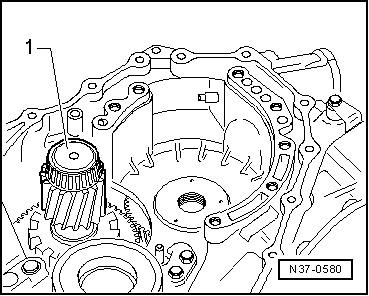

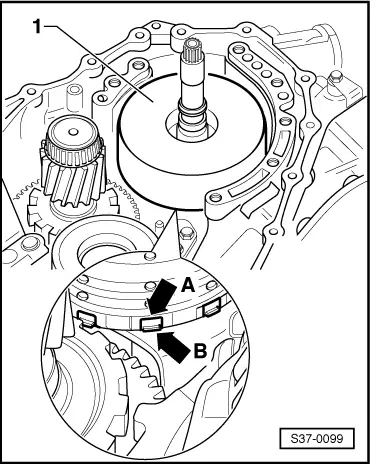

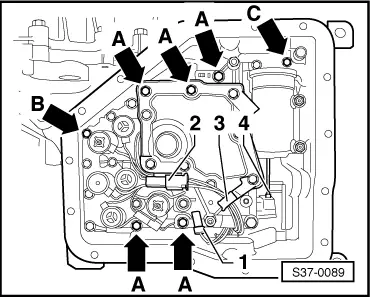

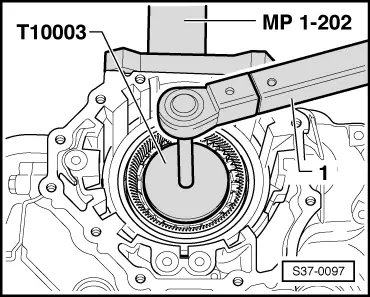

| Fit slide valve body and insert the bolt of the shift segment in the slot of the manual slider -4-. |

| –

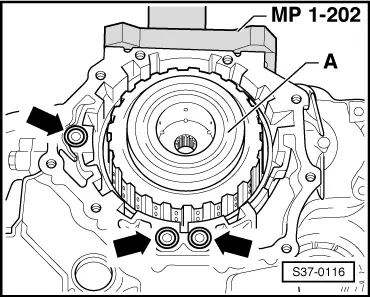

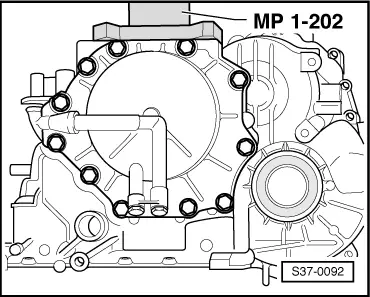

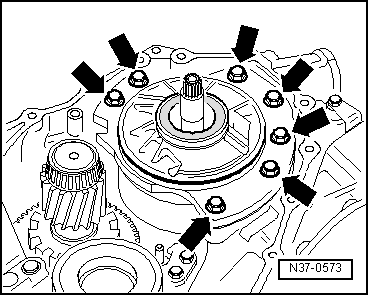

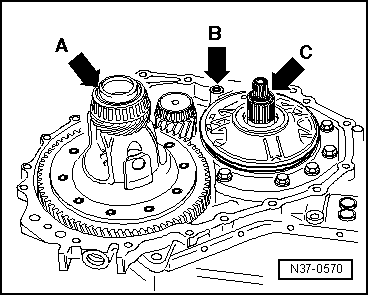

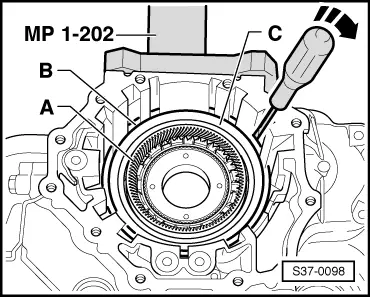

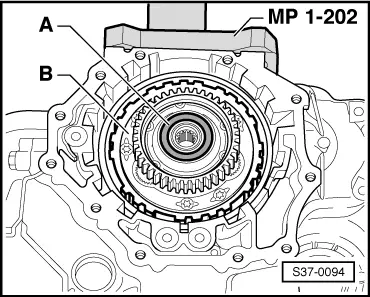

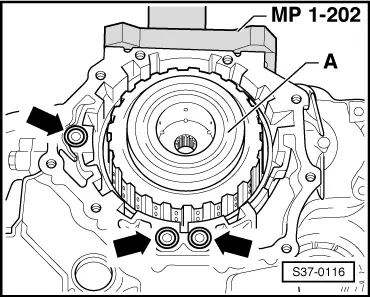

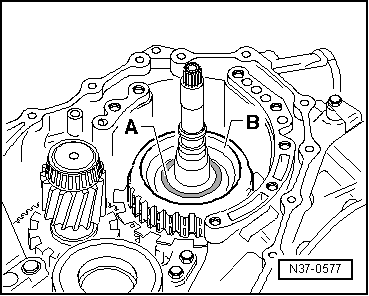

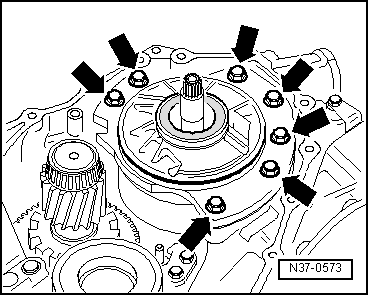

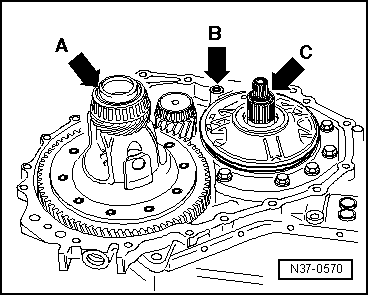

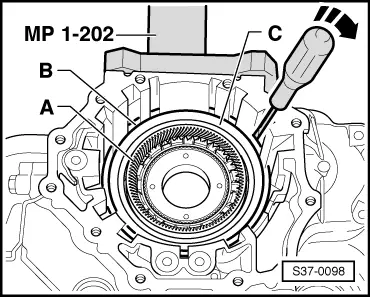

| Tighten screws -arrows A through C- by hand, pay attention to the different screw lengths. |

| t

| Screws -arrows A- = M6 x 80 mm |

| t

| Screw -arrow B- = M6 x 68 mm |

| t

| Screw -arrow C- = M6 x 40 mm |

| –

| Subsequently, tighten the screws gradually and crosswise to 8 Nm. |

| –

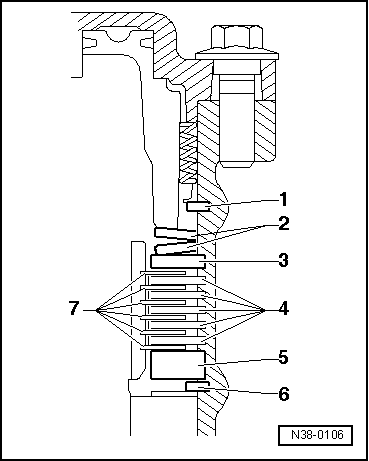

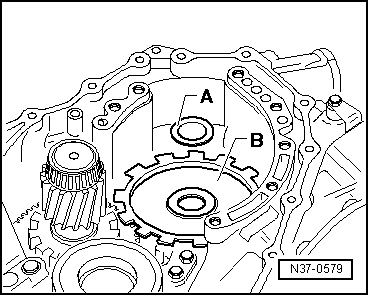

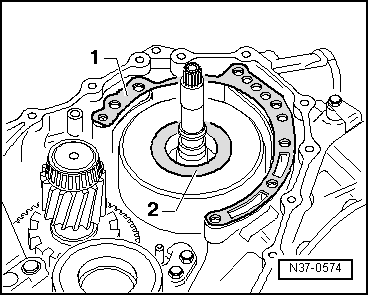

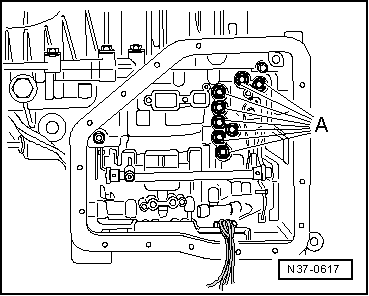

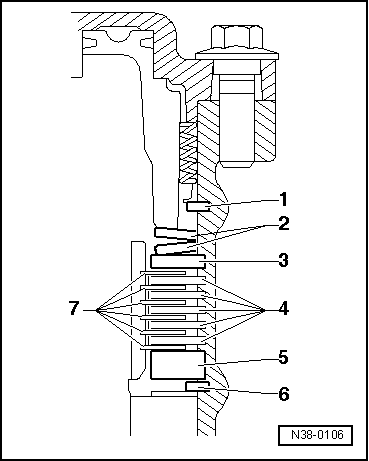

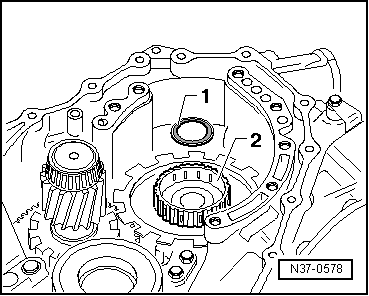

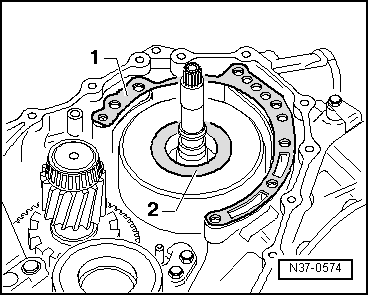

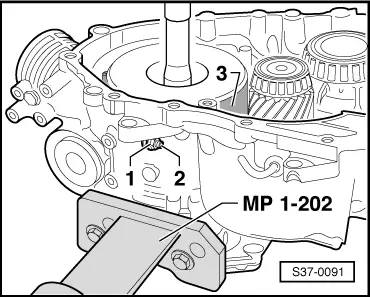

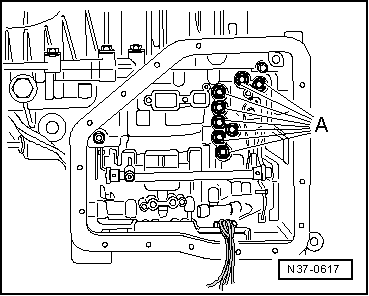

| Insert plug for the solenoid valves -2-. |

| –

| Hook wiring loom onto bracket -3-. |

| –

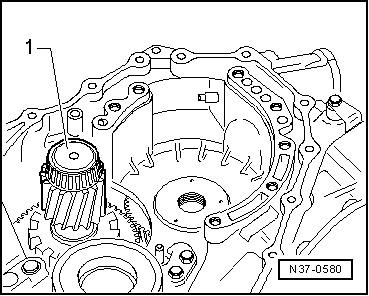

| Clip on sender -1- for ATF temperature. |

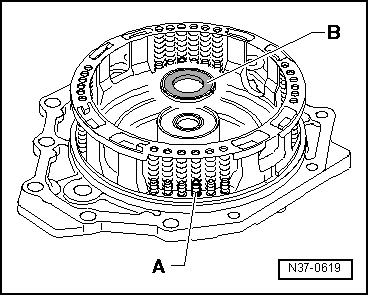

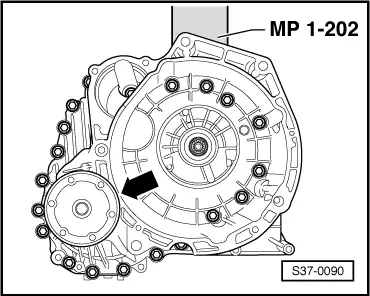

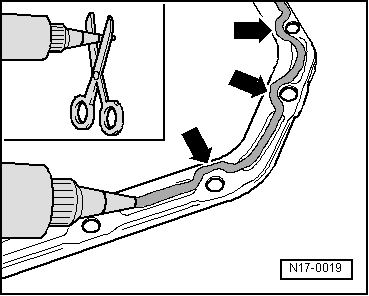

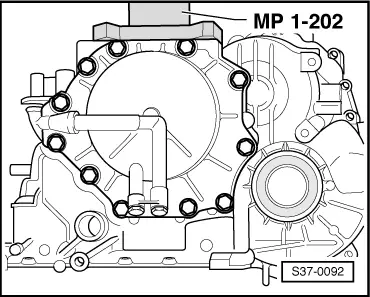

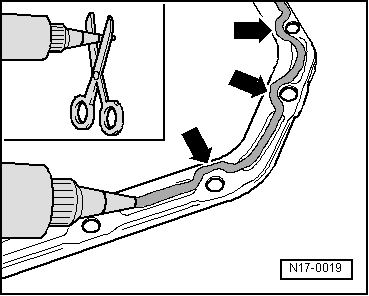

| Apply sealant -D 176 404 A2- to the oil pan as follows: |

|

|

|

Note

Note

Note

Note