Fabia Mk1

Note

Note| t | When installing new pinions or a new output shaft observe the technical data → Chapter. |

| t | Insert all bearings, gears and synchronizer rings in the gearbox with gear oil. |

| t | Do not interchange the synchronizer rings. If re-used always assign to the original gear. |

| 1 - | Nut, 60 Nm |

| q | always replace |

| 2 - | Disc spring |

| q | Fitting position: curved side points to gearbox housing cover |

| 3 - | Supporting ring |

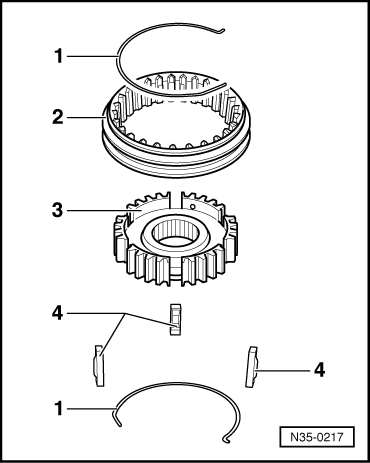

| 4 - | Spring |

| q | Fitting position → Fig. |

| 5 - | 5th gear sliding sleeve |

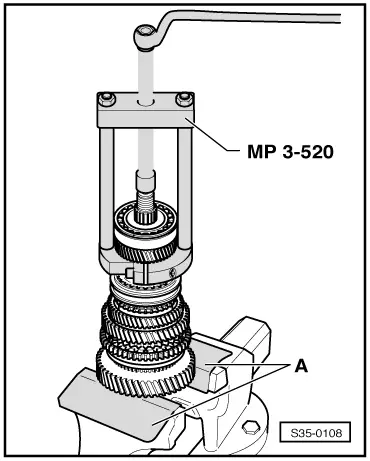

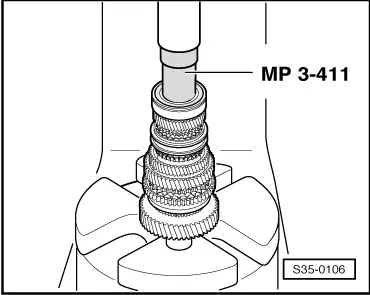

| q | removing and installing → Fig. and → Fig. |

| 6 - | 5th gear synchronizer body |

| q | removing and installing → Fig. and → Fig. |

| 7 - | Arresters (3 pieces) |

| q | Fitting position → Fig. |

| 8 - | 5th gear synchronizer ring |

| q | check for wear → Fig. |

| 9 - | 5th gear sliding gear |

| 10 - | Needle bearing |

| 11 - | Bushing for needle bearing |

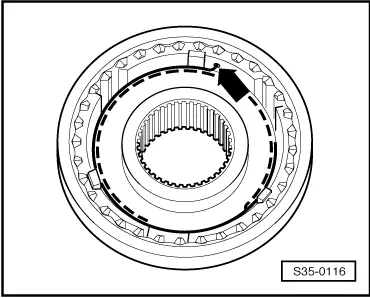

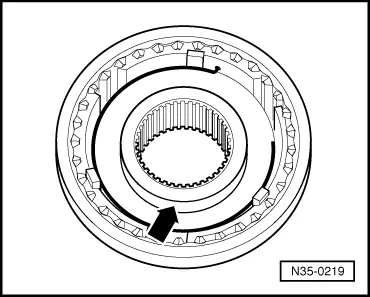

| q | Fitting position: The oil pockets -arrow- point towards the 5th gear synchronizer body. |

| 12 - | Gearbox housing |

| 13 - | Grooved ball bearing |

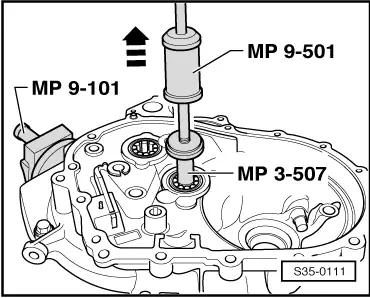

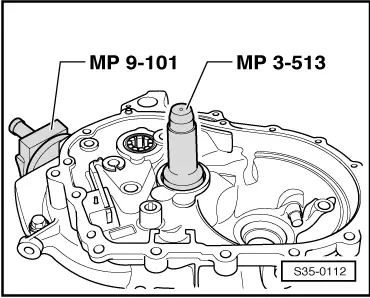

| q | remove → Fig. |

| q | pressing on → Fig. |

| 14 - | 4th gear sliding gear |

| 15 - | Circlip |

| q | replace |

| 16 - | 4th gear synchronizer ring |

| q | check for wear → Fig. |

| 17 - | Spring |

| 18 - | Sliding sleeve 3rd and 4th gear |

| 19 - | Synchronizer body for 3rd and 4th gear |

| 20 - | Arresters for synchronizer body (3 pieces) |

| 21 - | Sliding sleeve with 3rd and 4th gear synchronizer body |

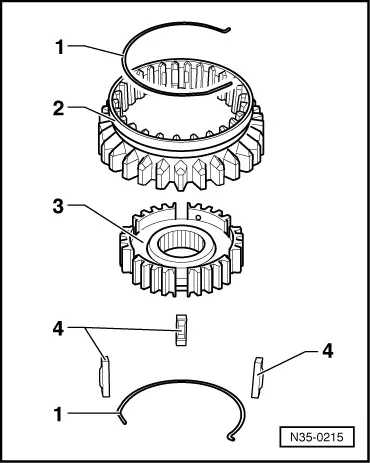

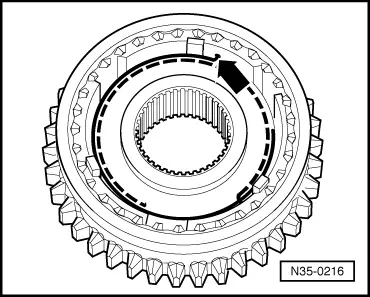

| q | Assembling the sliding sleeve with synchronizer body → Fig. and → Fig. |

| q | Fitting position of the sliding sleeve with synchronizer body → Fig. |

| 22 - | 3rd gear synchronizer ring |

| q | check for wear → Fig. |

| 23 - | 3rd gear sliding gear |

| 24 - | Washer |

| q | holds the thrust washers → Item in the correct position on the output shaft |

| 25 - | 2nd and 3rd gear thrust washers |

| 26 - | 2nd gear sliding gear |

| 27 - | 2nd gear synchronizer ring |

| q | check for wear → Fig. |

| 28 - | Sliding sleeve with 1st and 2nd gear synchronizer body |

| q | Assembling the sliding sleeve with synchronizer body → Fig. and → Fig. |

| 29 - | 1st gear synchronizer ring |

| q | check for wear → Fig. |

| 30 - | 1st gear sliding gear |

| 31 - | Output shaft |

| q | is paired with the gear pinion of the final drive, always replace together |

| 32 - | Cylindrical-roller bearing |

| q | removing → Fig. |

| q | pressing on → Fig. |

| q | Fitting position: the marking on the bearing points upwards |

| 33 - | Supports |

| q | for oil supply |

| 34 - | Washer |

| 35 - | 10 Nm |

| 36 - | Clutch housing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

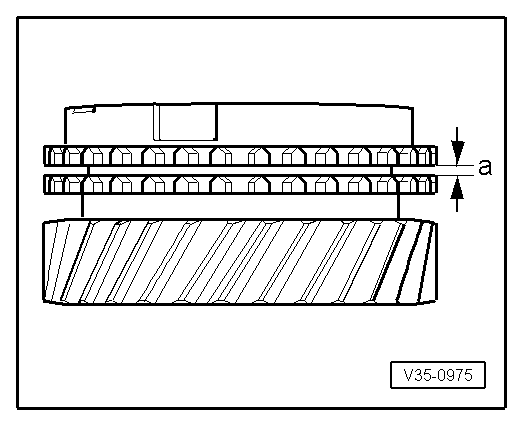

| Fitting dimension | Wear limit | |

| Clearance “a” | 1,2 to 1,8 mm | 0,5 mm |

|

|

|

|