Fabia Mk1

| 1 - | Gearbox housing |

| q | if replaced: Setting the output shafts and differential gear → Chapter |

| q | as of gearbox manufacturing date 08 01 6 the threaded bores for the oil filler plug and oil drain plug are modified from M24 x 1.5 to M22 x 1.5 |

| q | modified as of gearbox manufacturing date 10 04 6 in the area of the support for the grooved ball bearing/drive shaft → Chapter |

| q | assign components via → Electronic Catalogue of Original Parts |

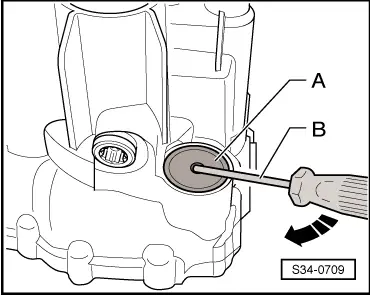

| 2 - | Cap |

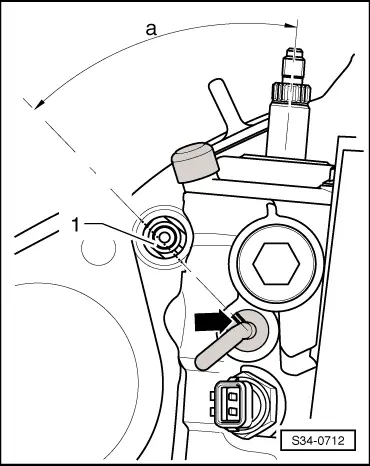

| q | removing → Fig. |

| q | inserting → Fig. |

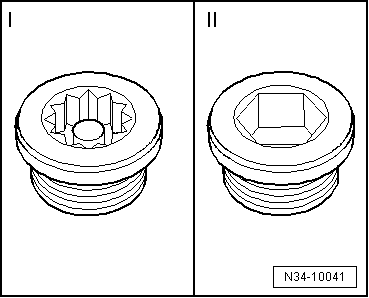

| 3 - | Oil drain plug |

| q | pay attention to different version → Fig. |

| q | Splined nut, 45 Nm |

| q | Allan screw, 30 Nm |

| 4 - | Gasket ring |

| q | always replace → Electronic Catalogue of Original Parts |

| q | no longer applicable for oil filler plug or oil drain plug with thread M22 x 1.5 mm |

| 5 - | Oil filler plug |

| q | pay attention to different version → Fig. |

| q | Splined nut, 45 Nm |

| q | Allan screw, 30 Nm |

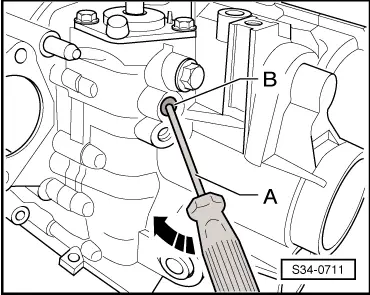

| 6 - | Locking angle |

| q | for setting the gearshift mechanism → Chapter |

| q | can be replaced without disassembling gearbox |

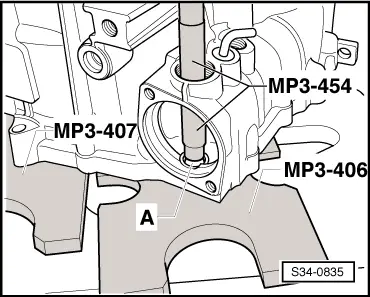

| q | removing → Fig. |

| q | Fitting position → Fig. |

| q | inserting → Fig. |

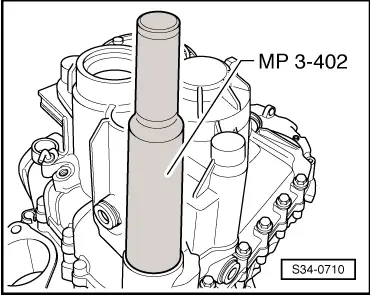

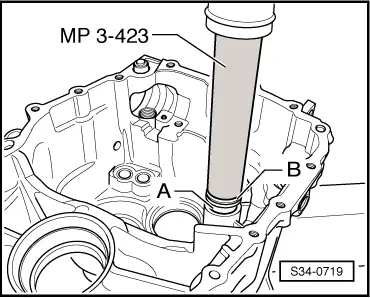

| 7 - | Bushing |

| q | for selector rods |

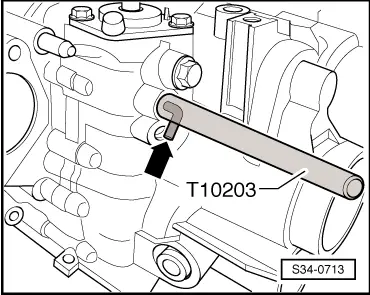

| q | removing → Fig. |

| q | inserting → Fig. |

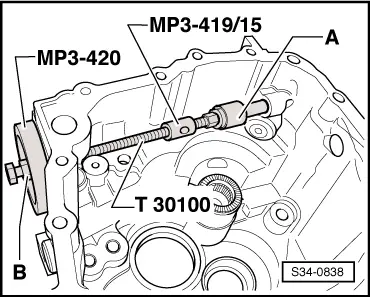

| 8 - | Serrated sleeve |

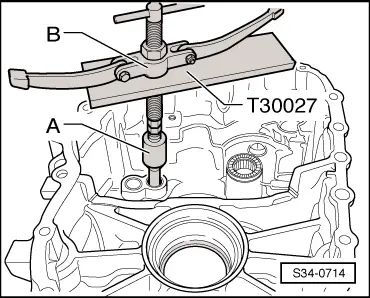

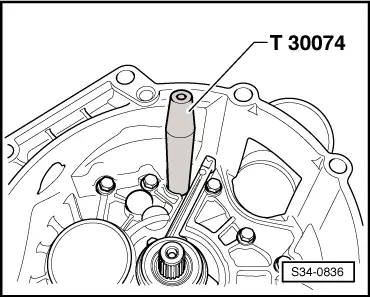

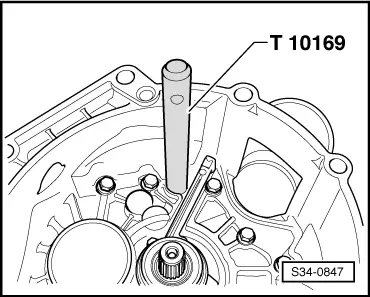

| q | press out with gearbox disassembled → Fig. |

| q | drive out without disassembling gearbox → Fig. |

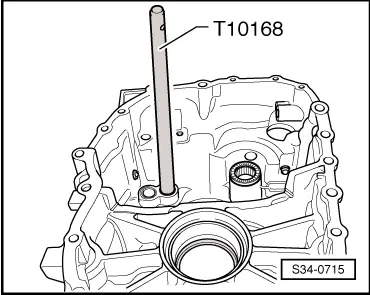

| q | inserting → Fig. |

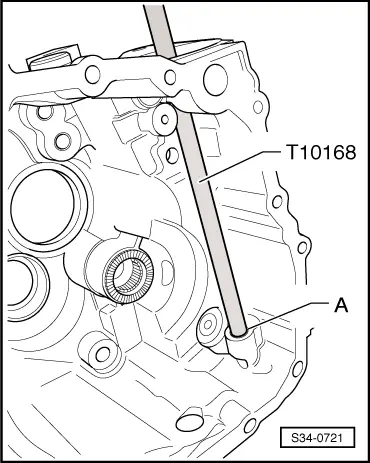

| 9 - | Needle bushing |

| q | for reverse shaft |

| q | replace after each disassembly → electronic catalogue of original parts |

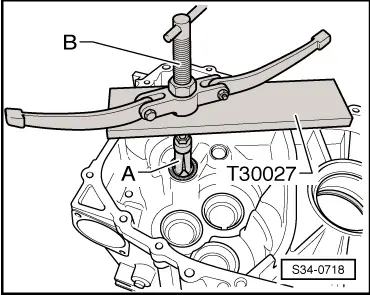

| q | removing → Fig. |

| q | installing → Fig. |

| 10 - | Outer ring/tapered-roller bearing |

| q | for output shaft 5th/6th and reverse gear |

| q | removing and installing → Chapter |

| q | if replaced: Setting output shaft 5th/6th and reverse gear → Chapter |

| 11 - | Adjusting washer |

| q | for output shaft 5th/6th and reverse gear |

| q | Setting overview → Chapter |

| 12 - | Outer ring/tapered-roller bearing |

| q | for output shaft gears 1 through 4 |

| q | removing and installing → Chapter |

| q | if replaced: Setting output shaft gears 1 through 4 → Chapter |

| 13 - | Adjusting washer |

| q | for output shaft gears 1 through 4 |

| q | Setting overview → Chapter |

| 14 - | Outer ring/tapered-roller bearing |

| q | for differential |

| q | removing and installing → Chapter |

| q | if replaced: Adjusting the differential gear → Chapter |

| 15 - | Adjusting washer |

| q | for differential |

| q | Setting overview → Chapter |

| 16 - | Bushing |

| q | for gearshift shaft |

| q | removing → Fig. |

| q | inserting → Fig. |

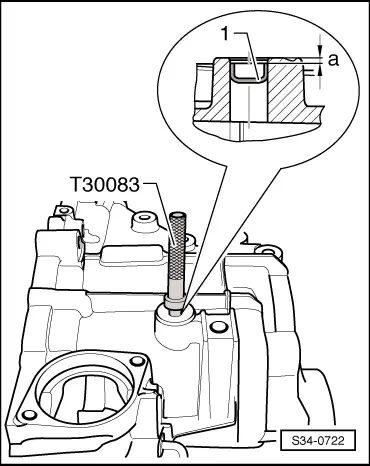

| 17 - | Plug |

| q | drive out with drift |

| q | inserting → Fig. |

| 18 - | Gasket ring |

| q | for left flange shaft |

| q | replace → Chapter |

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|