| –

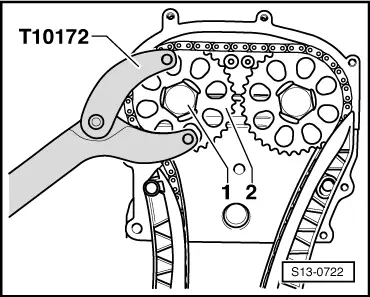

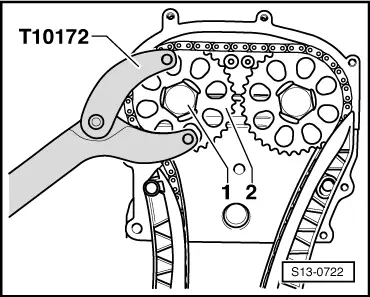

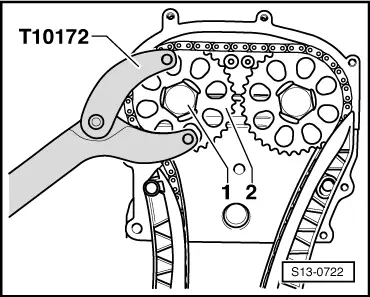

| Tighten the screw -1- of the camshaft sprockets -2- to 50 Nm (use counterholder -T10172 -). |

| –

| Then, torque the bolts a further 90° (1/4 turn) with a rigid wrench. |

|

| Tightening torque: 50 Nm + torque a further 90° (1/4 turn) |

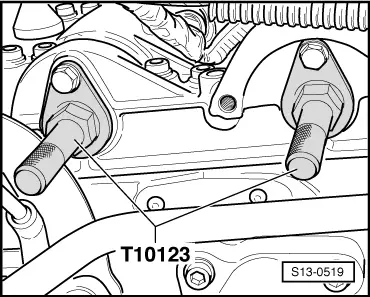

Note | The assistance of a 2nd mechanic is required for this work. |

| –

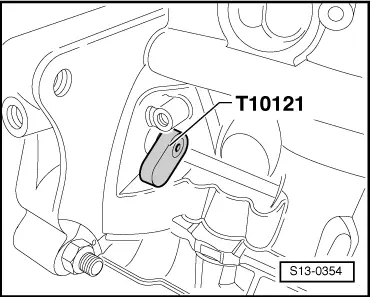

| Carefully crank engine at least 2 revolutions to ensure that no valve touches the piston when the engine is started, check timing again → Chapter. |

| Further installation occurs in reverse order. |

| –

| Check position of camshaft to crankshaft in the display group 012 display field 3 and 4. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note