Fabia Mk2

Note

Note| t | Before installing heat the inner ring of the tapered-roller bearing to 100°C. |

| t | Replace both tapered-roller bearings together. |

| t | Removing and installing differential gear → Chapter. |

| t | When replacing the tapered-roller bearings, the differential housing, the gearbox housing or the clutch housing, set the differential gear → Chapter. |

| 1 - | Gearbox housing |

| 2 - | Adjusting washer |

| q | for the differential gear |

| q | Determine thickness → Chapter |

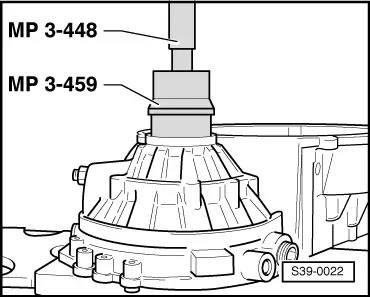

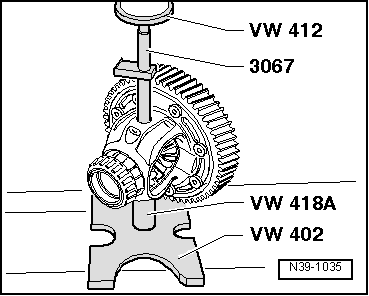

| 3 - | Outer ring/tapered-roller bearing |

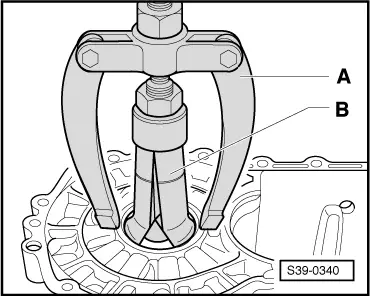

| q | removing → Fig. |

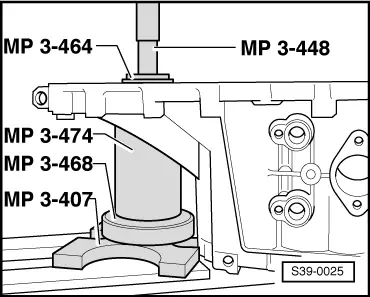

| q | installing → Fig. |

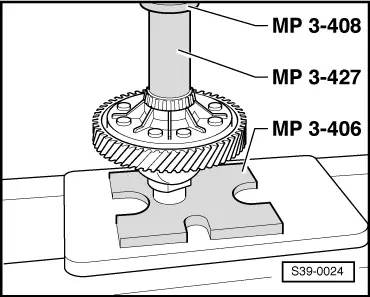

| 4 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 5 - | Differential gear housing |

| q | with gear pinion for final drive |

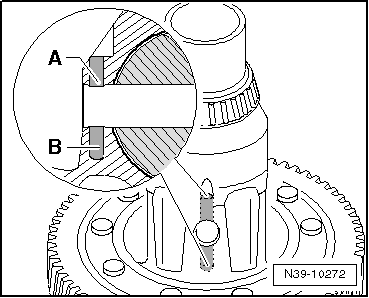

| q | The hole of the tensioning sleeve is adapted to the length of the tensioning sleeve → Fig. |

| q | Assignment → Electronic Catalogue of Original Parts |

| 6 - | Drive wheel for speedometer |

| q | if present, place it on the differential gear housing up to the stop before pressing on the inner ring Pos. 7 |

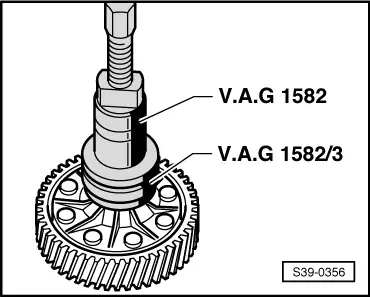

| 7 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

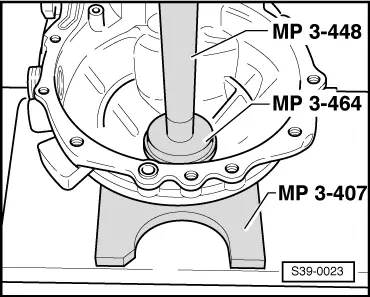

| 8 - | Outer ring/tapered-roller bearing |

| q | pressing out → Fig. |

| q | installing → Fig. |

| 9 - | Clutch housing |

| 10 - | Gasket ring with bushing |

| q | for right flange shaft |

| q | one-piece (a component part) |

| q | replace gasket ring together with bushing in the event of damage to the gasket ring → Chapter |

| 11 - | 25 Nm |

| q | screw to threaded connector Pos. 19 to attach the flange shaft |

| 12 - | Flange shaft |

| q | left - removing and installing → Chapter |

| q | right - removing and installing → Chapter |

| 13 - | Pressure spring for flange shaft |

| q | fitted behind flange shaft |

| 14 - | Thrust washer |

| q | Fitting position: Collar towards pressure spring → Fig. |

| 15 - | Conical ring |

| q | with slots for thrust washer catch |

| q | Fitting position: Cone towards differential gear housing |

| 16 - | Circlip |

| q | holds the conical ring, stop disc and pressure spring in position when the flange shaft is removed |

| 17 - | Stop disc compound |

| q | insert with gear oil |

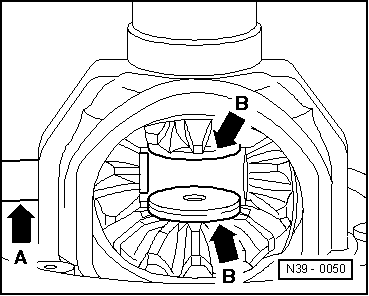

| 18 - | Large differential bevel gear |

| q | installing → Fig. |

| 19 - | Threaded part |

| q | installing → Fig. |

| 20 - | Differential bevel gear shaft |

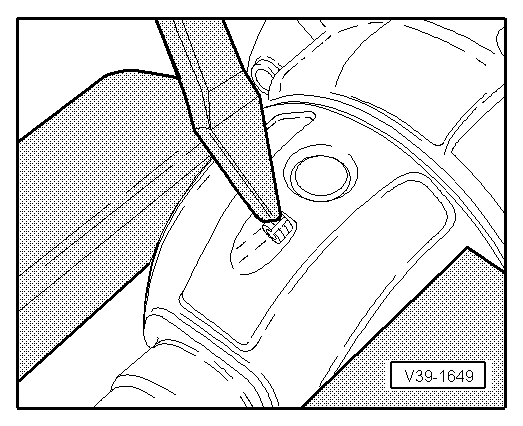

| q | remove in combination with short tensioning sleeve → Fig. |

| q | remove in combination with long tensioning sleeve → Fig. |

| q | installing → Fig. |

| 21 - | Tensioning sleeve |

| q | to secure the differential bevel gear shaft |

| q | Tensioning sleeves having different lengths are mounted |

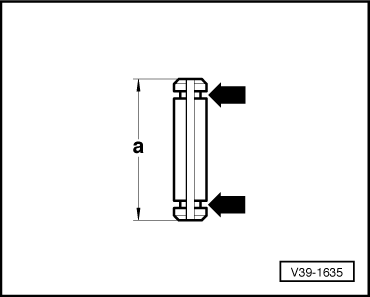

| q | Difference between the tensioning sleeves → Fig. |

| q | short tensioning sleeve: removing and installing → Fig. |

| q | long tensioning sleeve: is cut when removing → Fig. |

| q | long tensioning sleeve: installing → Fig. |

| 22 - | Small differential bevel gear |

| q | installing → Fig. |

| 23 - | Sealing ring |

| q | for left flange shaft |

| q | replace with installed gearbox → Chapter |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

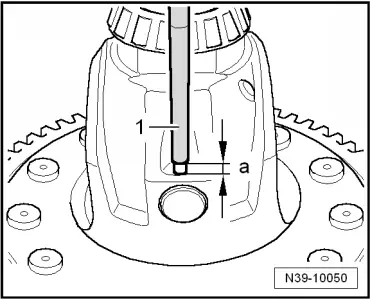

| Dimension „a“ (mm) | Distinguishing feature |

| 28.5 (short tensioning sleeve), removing and installing → Fig. | round slot -arrows- |

| 36.0 (long tensioning sleeve), remove → Fig., install → Fig. | no round slot |

|

|

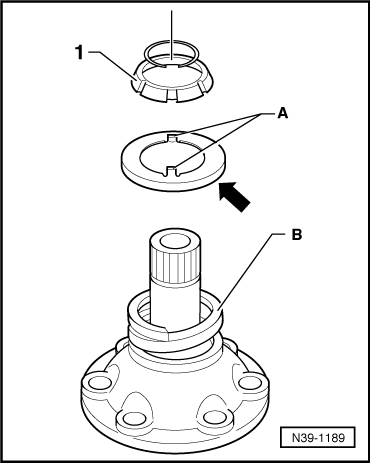

| Bore | Length of tensioning sleeve (mm) |

| -A- | 28.5 (short tensioning sleeve) |

| -A- and -B- | 36.0 (long tensioning sleeve) |

|

|

|

|

|

|

|

|

|

|