Fabia Mk2

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

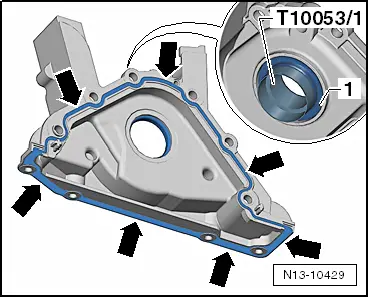

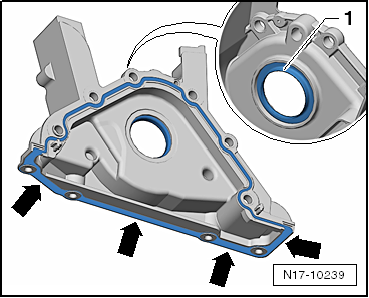

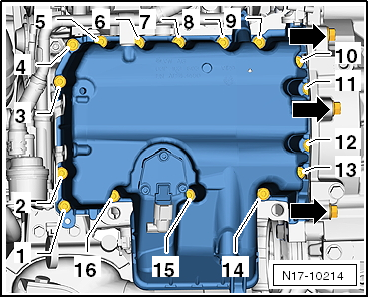

| Stage | Screws | Tightening torque |

| 1 | -1 … 16- | crosswise to 5 Nm |

| 2 | -Arrows- | 40 Nm |

| 3 | -1 … 16- | crosswise to 15 Nm |

|

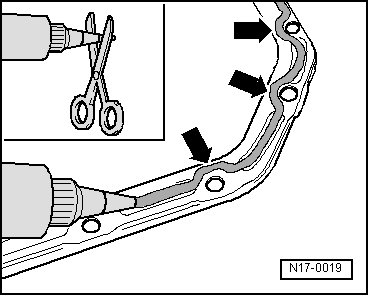

WARNING

WARNING Caution

Caution