Note | t

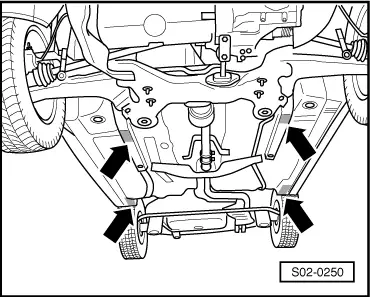

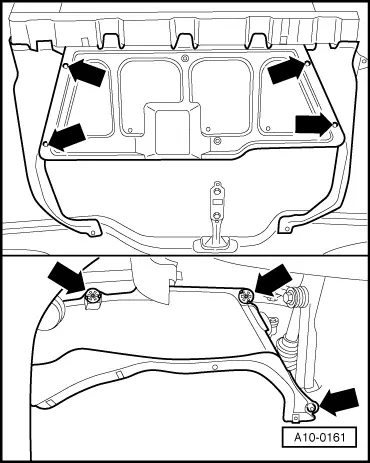

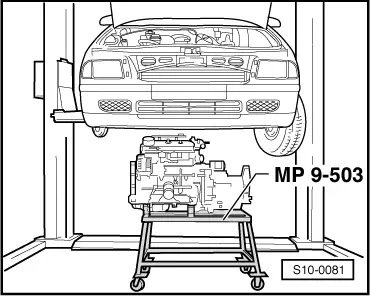

| The engine is removed downwards together with the gearbox. |

| t

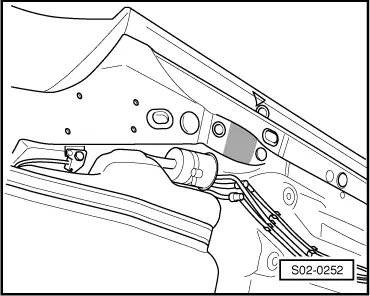

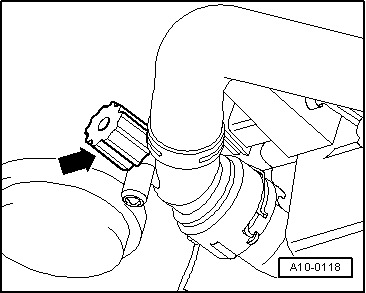

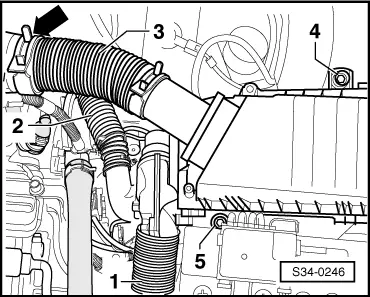

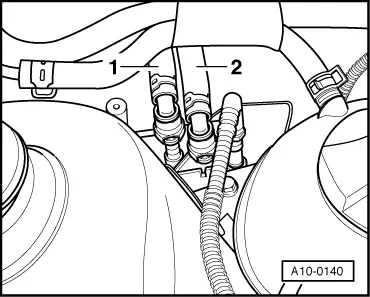

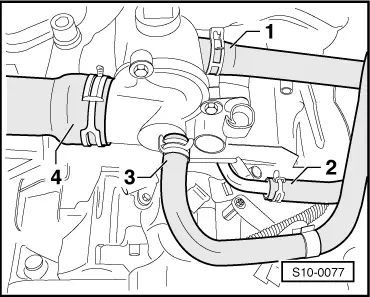

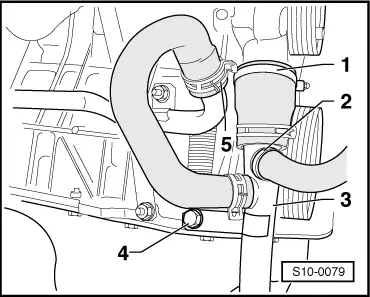

| The hose connections are secured with screw-type clips, spring-type clips or clamp-type clips. Always replace warm-type clamps with spring strap clips or screw clamps. |

| t

| Fuel lines at the engine must only be secured with spring-type clips. The use of clamp-type or screw-type clips is not allowed. |

| t

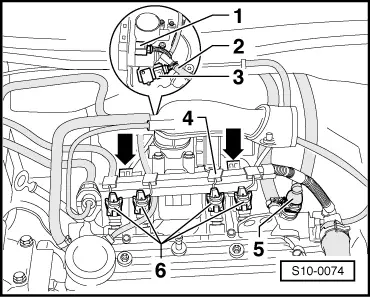

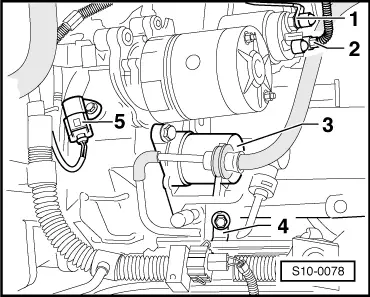

| Pay attention to the correct assignment of the relevant connectors, if necessary mark. |

| –

| On models fitted with a coded radio set, determine and note the coding. |

| –

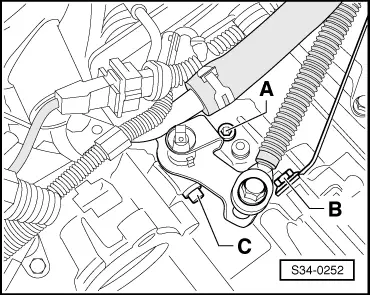

| Switch off the ignition and disconnect the battery earth strap. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING