Octavia Mk1

|

|

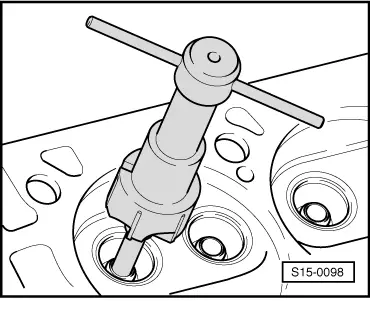

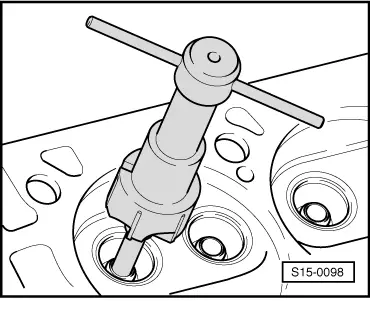

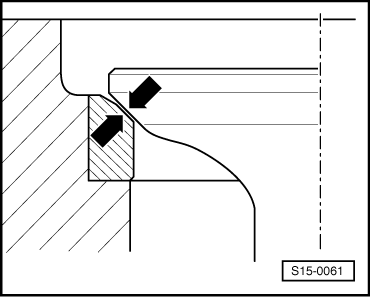

| Valve guide | Guide drift Ø mm |

| Inlet valve | 6,0 -0,01 |

| Exhaust valve |

|

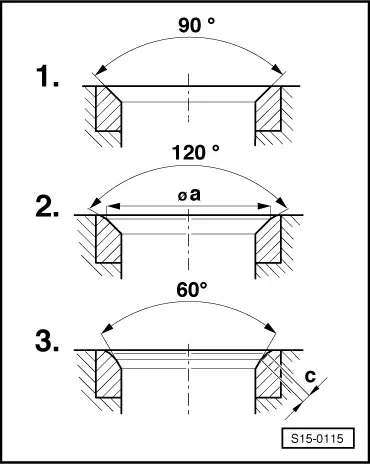

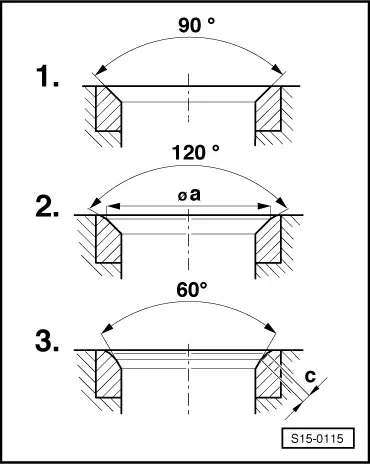

| Valve seat | Milling cutter Ø mm | ||

| 90° | 120° | 60° | |

| Inlet valve | 28 | 28 | 30 |

| Exhaust valve | 32 | 32 | 32 |

|

|

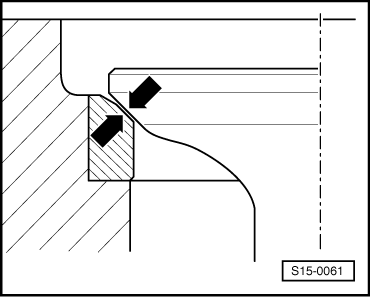

Note

Note

|

|

|

|

| Valve guide | Guide drift Ø mm |

| Inlet valve | 6,0 -0,01 |

| Exhaust valve |

|

| Valve seat | Milling cutter Ø mm | ||

| 90° | 120° | 60° | |

| Inlet valve | 28 | 28 | 30 |

| Exhaust valve | 32 | 32 | 32 |

|

|

Note

Note

|

|