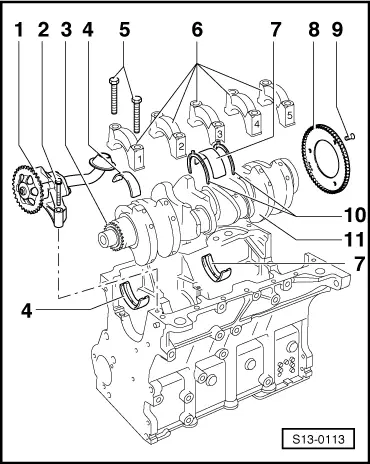

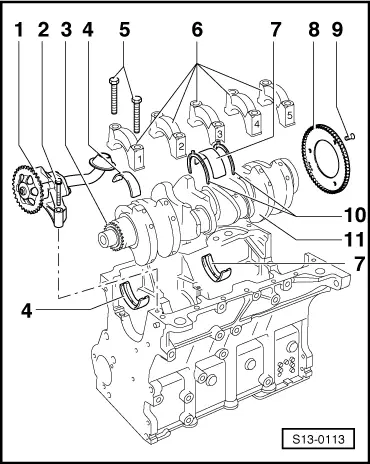

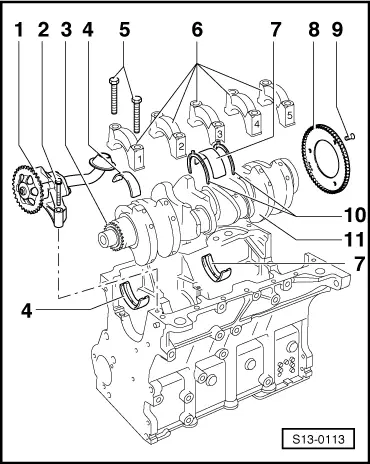

| Removing and installing crankshaft |

Note | t

| Before removing the crankshaft, ensure a suitable place is available for placing it down so that the sensor rotor (pos. 8) does not rest against anything or get damaged. |

| t

| Secure the engine with engine mount -MP 1-202- and distance sleeves - T30010- on the assembly stand -MP 9-101 - before performing assembly work. |

Note | t

| For engine with engine code AZJ |

| t

| Before removing the crankshaft, first of all remove the gearbox with balancing shafts → Chapter. |

| –

| for engine with identification characters AEG, APK, AQY and AZH |

| 4 - | Bearing shells 1, 2, 4 and 5 |

| –

| for bearing cap without lubricating groove |

| –

| for cylinder block with lubricating groove |

| –

| used bearing shells must not be mixed up (mark) |

| –

| only use → Fig. bearing shells with the same colour coding when replacing |

| 5 - | 65 Nm + torque a further 90° (1/4 turn) |

| –

| Bearing cap 1: belt pulley side |

| –

| Bearing cap 3: with recesses for thrust washers |

| –

| retaining lugs of the bearing shells of the cylinder block/bearing cap must be on top of one another |

| –

| for engine speed sender -G28 - |

| –

| assembly only possible in one position -holes offset- |

| 9 - | 10 Nm + torque a further 90° (1/4 turn) |

| –

| for bearing cap and cylinder block, bearing 3 |

| –

| pay attention to the marking |

| –

| pay attention to different version |

| –

| Axial play when new: 0.07…0.23 mm |

| –

| Crankshaft bearing journal: Ø 54.00 mm |

| –

| Conrod bearing journal: Ø 47.80 mm |

|

|

|

Note

Note Note

Note

Note

Note Note

Note