| Disassembling and assembling piston and conrod |

| For engine with identification characters AEG, APK, AQY and AZH |

Note | Secure the engine with engine mount -MP 1-202- and distance sleeves - T30010- on the assembly stand -MP 9-101 - before performing assembly work. |

| –

| pay attention to different version |

| –

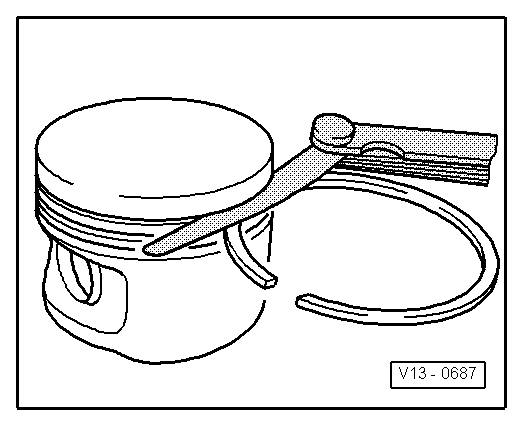

| use piston ring pliers for removing and installing |

| –

| Oil scraper ring 2 part |

| –

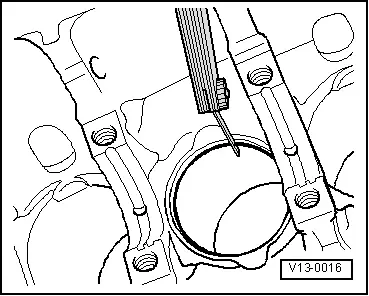

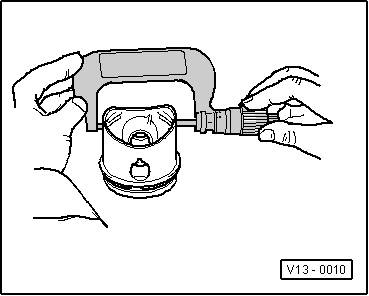

| Inspect gap clearance → Fig. |

| –

| Inspect end clearance → Fig. |

| –

| pay attention to different version |

| –

| mark installation position relative to conrod and mark matching cylinder with felt pen |

| –

| arrow on piston crown faces towards the belt pulley side |

| –

| pay attention to different version |

| –

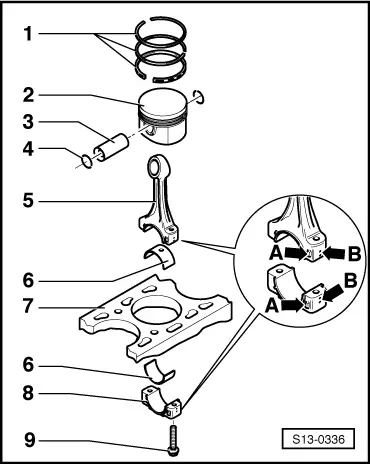

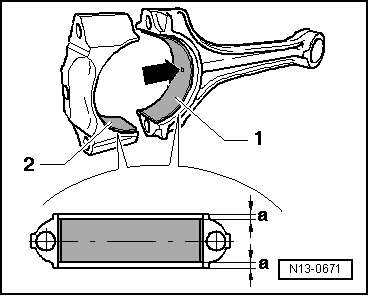

| mark assignment to cylinder see -arrow B- |

| Markings -arrow A- must be positioned one above the other and point to the belt pulley side |

| –

| with oil drilling for lubricating piston pin |

| –

| pay attention to different version |

| –

| mark assignment to cylinder see -arrow B- |

| Markings -arrow A- must be positioned one above the other and point to the belt pulley side |

| 5 - | 30 Nm + torque a further 90° (1/4 turn) |

| –

| oil thread and head contact surface |

| 6 - | Pressure relief valve, 27 Nm |

| 0.25…0.32 MPa (2.5...3.2 bar) overpressure |

| –

| replace without sealant |

| –

| do not mix up used bearing shells (mark) |

| –

| ensure tightly located in retaining lugs |

| –

| Axial play when new: 0.10...0.35 mm, wear limit: 0.4 mm |

| –

| with oil drilling for lubricating piston pin |

| –

| pay attention to different version |

| –

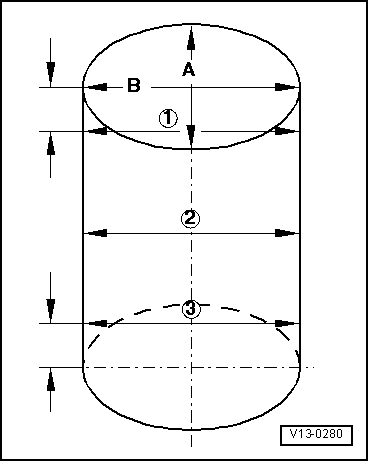

| inspect cylinder bore → Fig. |

| –

| replace together with nut Pos. 5 |

| –

| if stiff, heat piston to 60°C |

| –

| with drift -VW 222 A- removing and installing |

| For engine with engine code AZJ |

Note | Secure the engine with engine mount -MP 1-202- and distance sleeves - T30010- on the assembly stand -MP 9-101 - before performing assembly work. |

| –

| use piston ring pliers for removing and installing |

| –

| Oil scraper ring 2 part |

| –

| Inspect gap clearance → Fig. |

| –

| Inspect end clearance → Fig. |

| –

| mark installation position relative to conrod and mark matching cylinder with felt pen |

| –

| arrow on piston crown faces towards the belt pulley side |

| –

| if stiff, heat piston to 60°C |

| –

| with drift -VW 222 A- removing and installing |

| –

| always replace as a set only |

| –

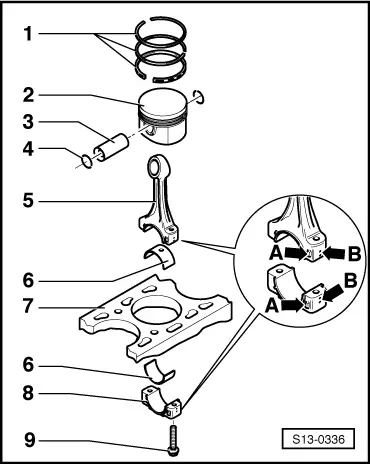

| mark assignment to cylinder see -arrow B- |

| –

| Fitting location: Markings -arrow A- must be positioned one above the other and point to the belt pulley side |

| –

| check fitting position → Fig. |

| –

| do not mix up used bearing shells (mark) |

| –

| insert bearing shells in the centre |

| –

| Axial play when new: 0.10...0.35 mm, wear limit: 0.4 mm |

| –

| inspect cylinder bore → Fig. |

| –

| mark assignment to cylinder see -arrow B- |

| 9 - | 30 Nm + torque a further 90° (1/4 turn) |

| –

| oil thread and head contact surface |

|

|

|

Note

Note Note

Note

Note

Note