Octavia Mk1

|

|

Note

Note

|

|

|

|

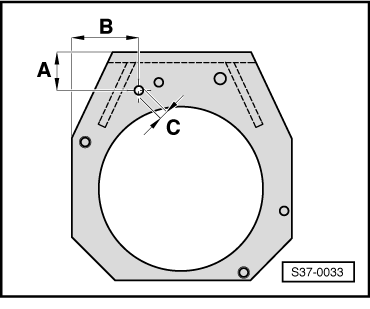

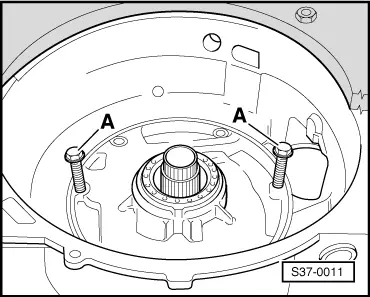

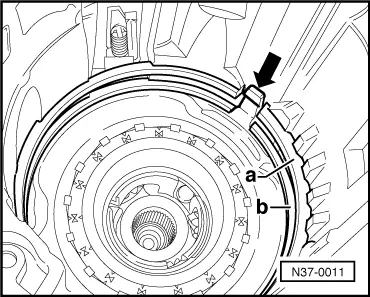

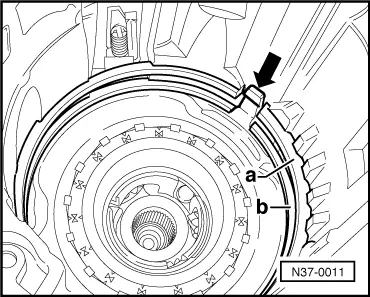

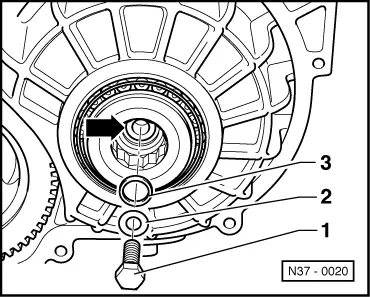

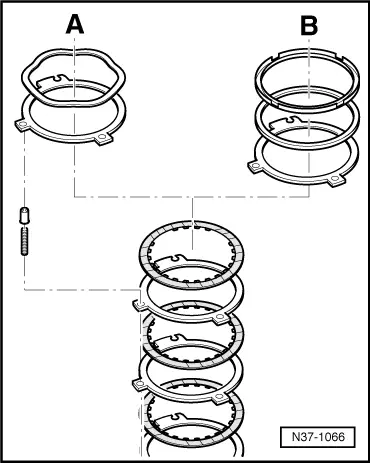

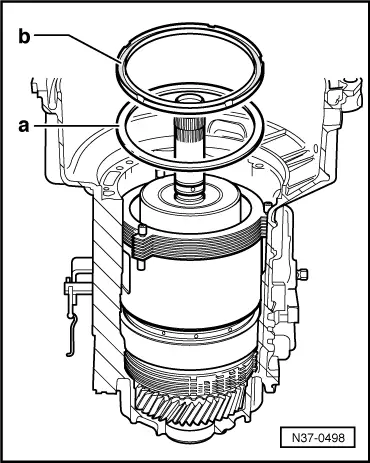

| -A- | = 55 mm | |

| -B- | = 96 mm | |

| Ø -C- | = 12 mm | |

Note

Note |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

WARNING

WARNING