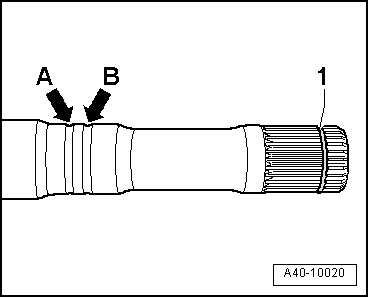

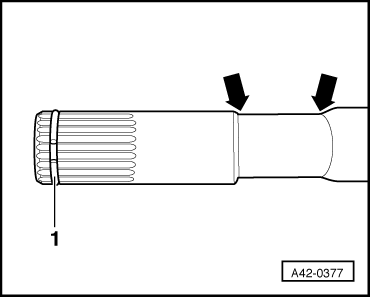

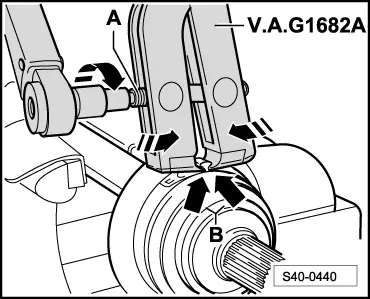

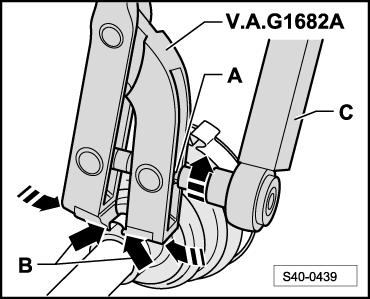

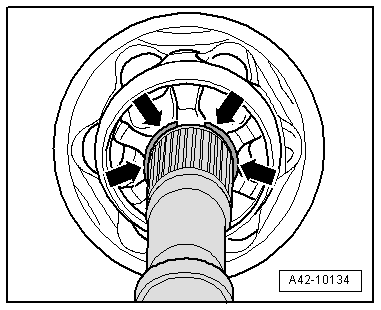

| Tighten the open warm-type clamp at the smaller diameter |

| –

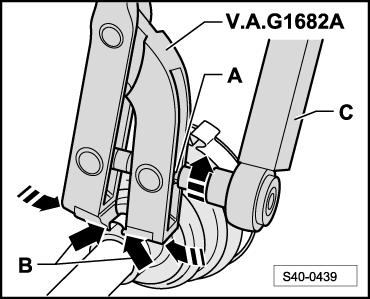

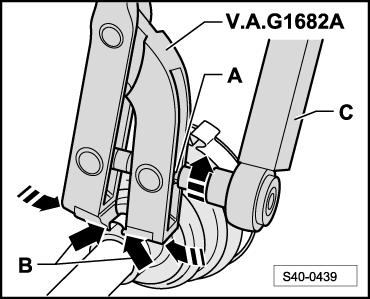

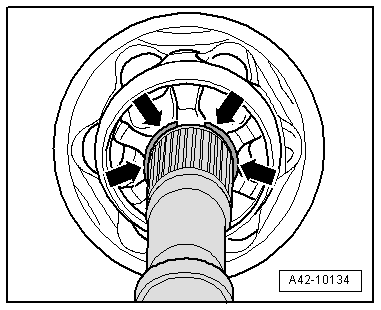

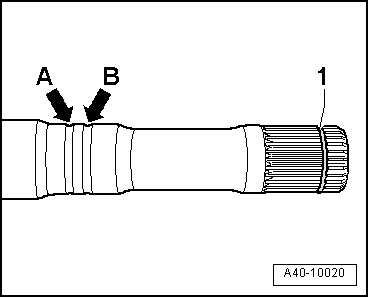

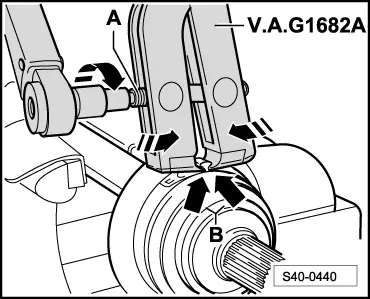

| Position the tensioning pliers as shown in the figure. Make sure the cutting edges of the pliers are positioned in the corners -arrows B- of the open warm-type clamp. |

| –

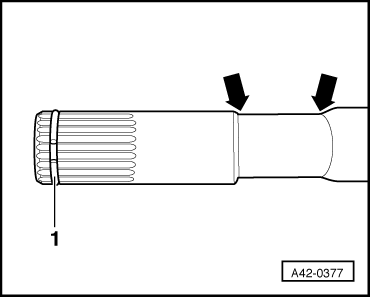

| Tighten the open warm-type clamp by turning the spindle with a torque wrench (do not tilt the pliers during this process.) |

Note | t

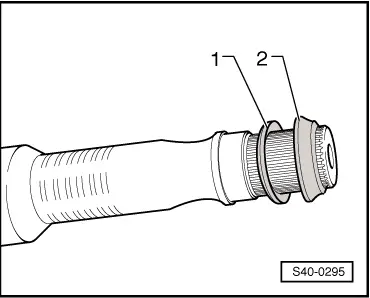

| In view of the hard material (as opposed to rubber) of the joint boot, which requires the use of a stainless steel open warm-type clamp, the latter can only be tightened with tensioning pliers, e. g. -V.A.G 1682 A-. |

| t

| Tightening torque: 25 Nm. |

| t

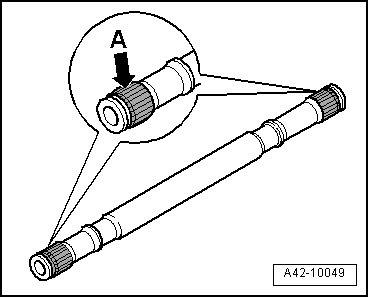

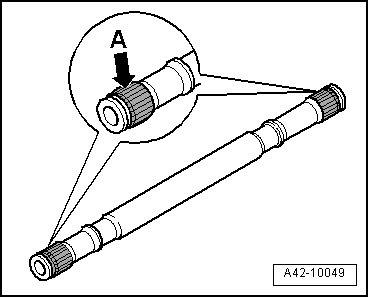

| Ensure that the thread of the spindle -A- of the pliers is smooth. Lubricate if necessary with grease. |

| t

| If it is not smooth, e.g. if the thread is dirty, the necessary clamping force of the open warm-type clamp is not reached at the given torque. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note