Octavia Mk2

| V-ribbed belt drive - Summary of components |

| Vehicles with engine identification characters BLR, BLX, BLY, BVX, BVY, BVZ |

| 1 - | Crankshaft-belt pulley |

| q | Contact surfaces must be free of oil and grease. |

| 2 - | 10 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 3 - | 23 Nm |

| 4 - | Lifting eye |

| 5 - | Tensioning device for V-ribbed belt |

| q | swivel tensioning device for V-ribbed belt with open-end wrench to slacken the V-ribbed belt |

| 6 - | Bracket for auxiliary units |

| q | observe the order of tightening up → Fig. |

| 7 - | Nut |

| 8 - | AC generator |

| q | removing and installing → Electrical System; Rep. Gr.27 |

| q | to facilitate positioning of the generator, drive the threaded bushings of the retaining screws at the generator slightly backwards |

| 9 - | 45 Nm |

| q | observe the order of tightening up → Fig. |

| q | insert using locking agent -D 000 600 A2- |

| 10 - | Bush |

| q | 2 pieces |

| 11 - | AC compressor |

| q | removing and installing → Heating, Air Conditioning; Rep. Gr.87 |

| 12 - | V-ribbed belt |

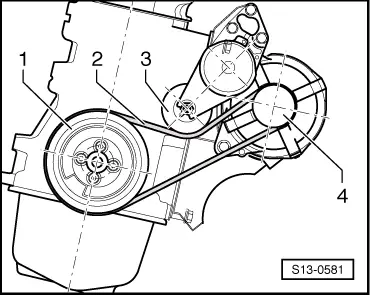

| q | Routing of the V-ribbed belt without AC compressor → Fig. |

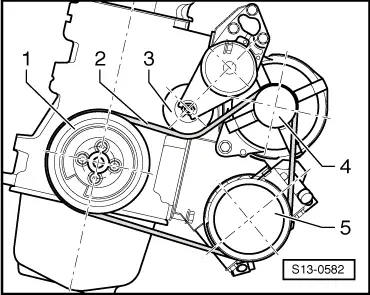

| q | Routing of the V-ribbed belt with AC compressor → Fig. |

| q | check for wear |

| q | do not kink |

| q | removing and installing → Chapter |

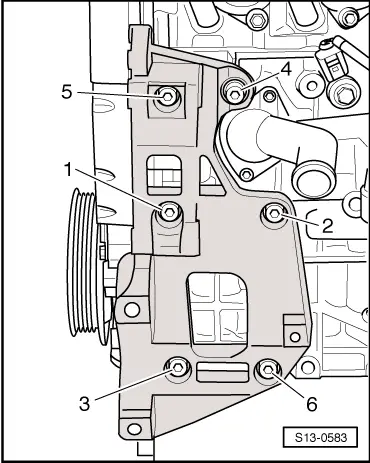

| Engine identification character BWA |

| 1 - | Bracket for auxiliary units |

| q | observe the order of tightening up → Fig. |

| 2 - | 23 Nm |

| 3 - | Threaded bushing |

| 4 - | AC generator |

| q | removing and installing → Electrical System; Rep. Gr.27 |

| q | to facilitate positioning of the generator, drive the threaded bushings of the retaining screws at the generator slightly backwards |

| 5 - | 45 Nm |

| q | observe the order of tightening up → Fig. |

| 6 - | Bush |

| q | 2 pieces |

| 7 - | 23 Nm |

| 8 - | AC compressor |

| q | removing and installing → Heating, Air Conditioning; Rep. Gr.87 |

| 9 - | V-ribbed belt |

| q | Routing of the V-ribbed belt without AC compressor → Fig. |

| q | Routing of the V-ribbed belt with AC compressor → Fig. |

| q | check for wear |

| q | do not kink |

| q | removing and installing → Chapter |

| 10 - | Crankshaft-belt pulley |

| q | Contact surfaces must be free of oil and grease. |

| 11 - | 20 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 12 - | 23 Nm |

| 13 - | Tensioning device for V-ribbed belt |

| q | swivel tensioning device for V-ribbed belt with open-end wrench to slacken the V-ribbed belt |

|

|

|

|

|

|