| Removing and installing oil pan |

| Special tools and workshop equipment required |

| t

| Flexible-head wrench SW 10 -3185- |

| t

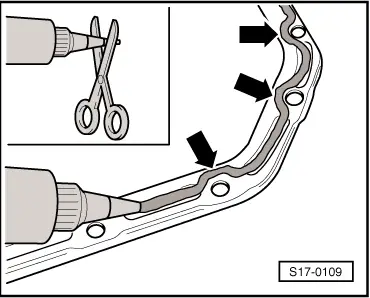

| Sealant remover gasket stripper (bearing code GST, bearing article no. R 34402), manufacturer Retech s.r.o. |

| t

| Cleaning and degreasing agent, e.g. -D 009 401 04- |

| t

| Protective goggles and gloves |

| t

| Silicone sealant -D 176 404 A2- |

Note | Observe safety measures and rules for cleanliness when working on vehicles with liquefied petroleum gas system (LPG) → Chapter. |

| –

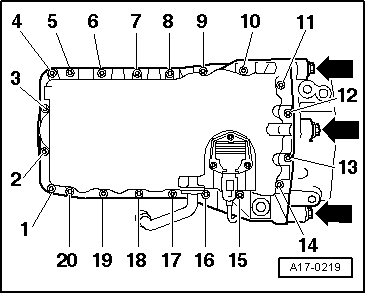

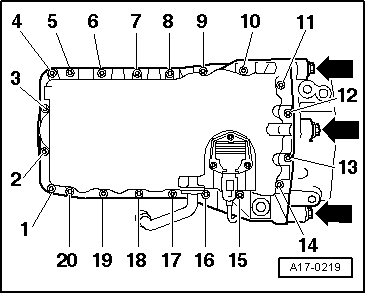

| Disconnect plug connection at oil level and oil temperature sender -G266-. |

| –

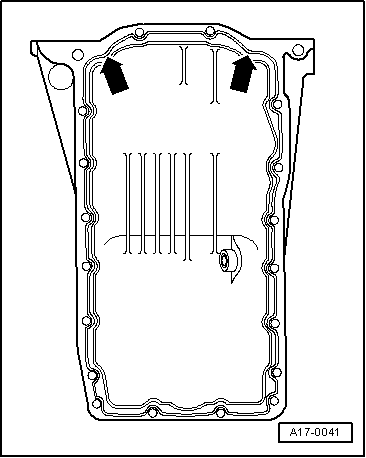

| Release the oil pan's fixing screws. |

Note | Slacken oil pan bolts at flywheel side with hinged wrench -3185 - and unscrew with wrench socket. |

| –

| Remove oil pan, if necessary release by applying slight blows with a rubber-headed hammer. |

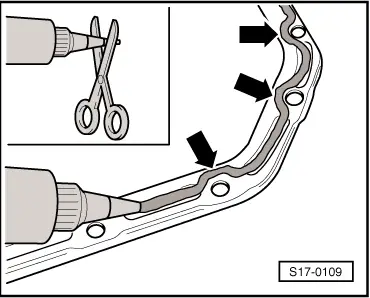

WARNING | Wear protective gloves when working with sealant and grease remover! |

|

| –

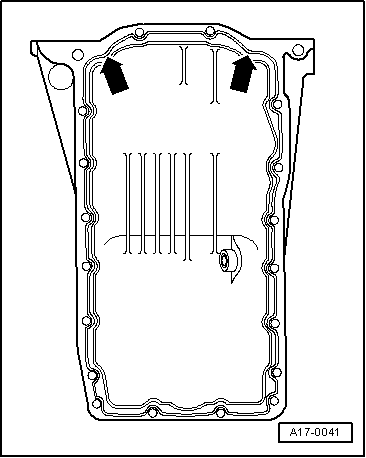

| Remove the remaining sealant from the sealing surface on the cylinder block (while doing so remove the baffle) and on the oil pan with chemical sealant remover. |

| –

| Degrease the sealing surfaces. |

| Installation is performed in the reverse order, pay attention to the following points: |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note