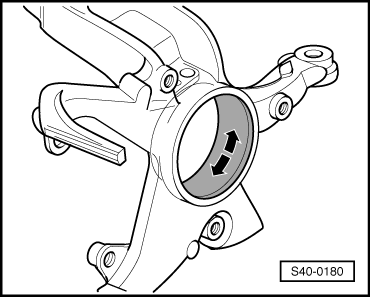

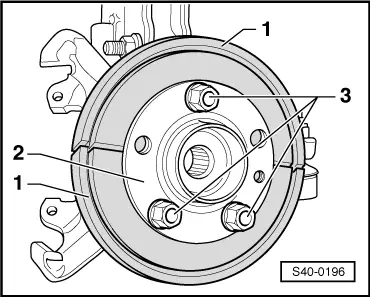

| Cover plate to wheel-bearing housing | 10 Nm |

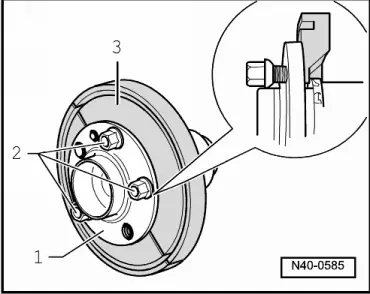

| Phillips head screw of brake disc to wheel hub with wheel bearing | 4 Nm |

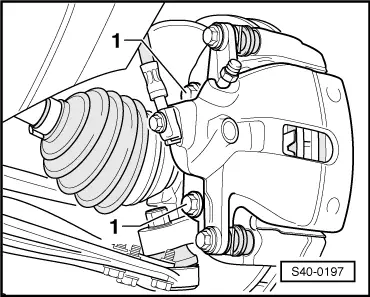

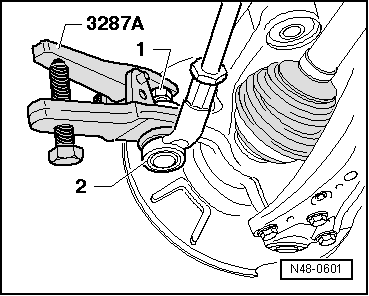

Twelve-point nut for securing the drive shaft to wheel hub| t

| Do not grease thread of the outer joint of the drive shaft. |

| 50 Nm + 45° |

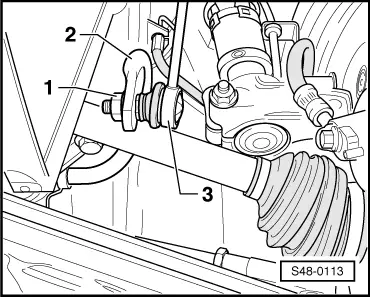

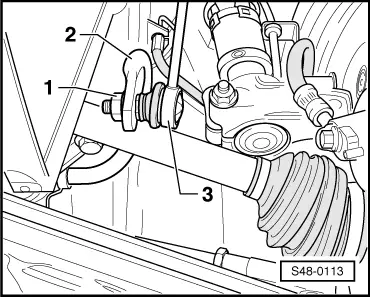

| Track rod/track rod end to steering arm | 20 Nm + 90° |

| Steering joint to track control arm | 40 Nm + 45° |

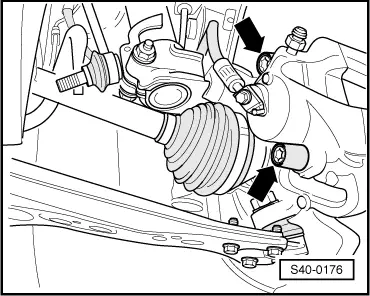

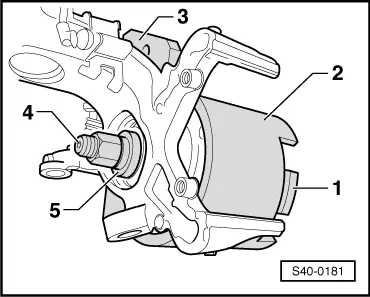

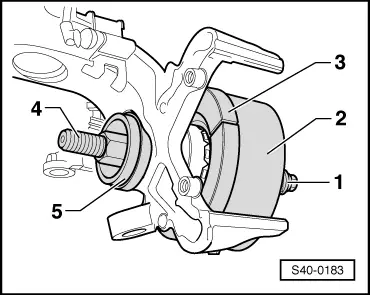

| FS-II brake caliper to wheel bearing housing | 25 Nm |

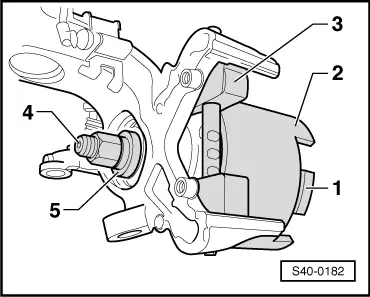

| FS-III brake caliper to wheel bearing housing | 28 Nm |

| Brake carrier with C54 brake caliper to wheel bearing housing | 125 Nm |

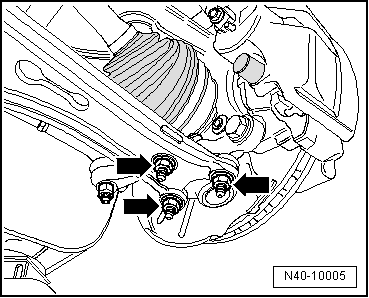

| ABS speed sensor to wheel-bearing housing | 8 Nm |

| Coupling rod to anti-roll bar | 40 Nm |

| Wheel bolts | → Chapter |

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution