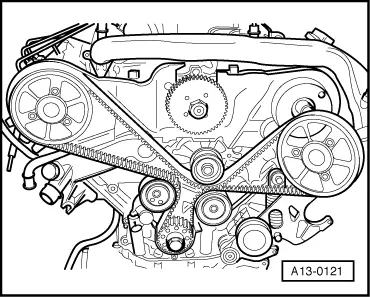

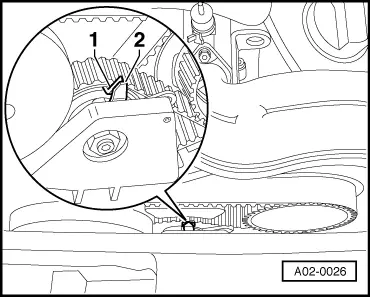

| Installing, set the timing |

| l

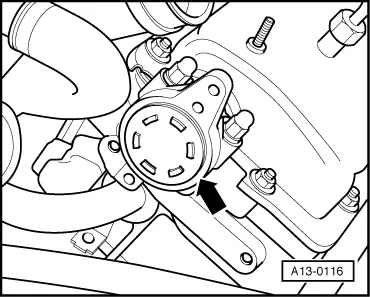

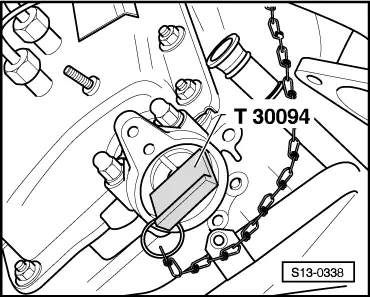

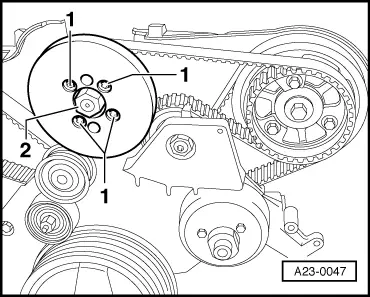

| Camshafts interlocked with the camshaft fixer/locators -T30094 (3458)-. |

| l

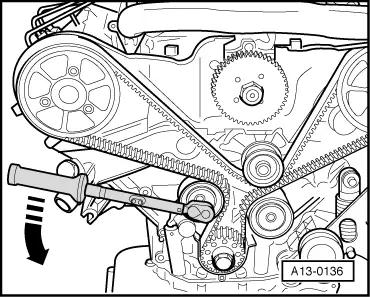

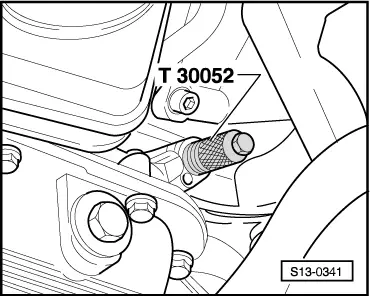

| Crankshaft locked into place by fixing screw -T30052 (3242)-. |

| l

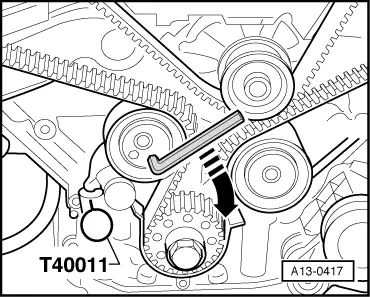

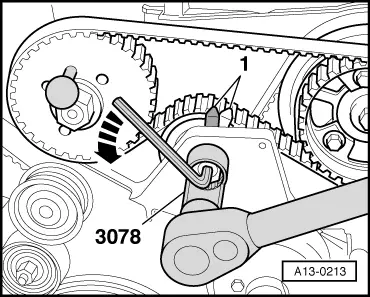

| The camshaft sprockets loosened. |

Note | t

| Also when carrying out repairs which necessitate taking the timing belt only off the camshaft sprockets, it is then necessary to set up the timing as follows. |

| t

| When rotating the camshaft, the crankshaft must not be positioned at TDC for any one cylinder. Risk of damaging valves and piston crowns. |

| t

| The camshaft fixer/locators -T30094 (3458)- must not be used as a counterholder. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note