| –

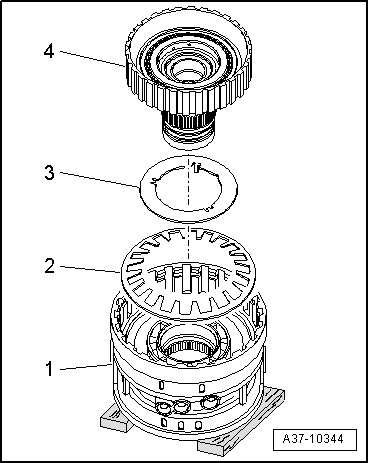

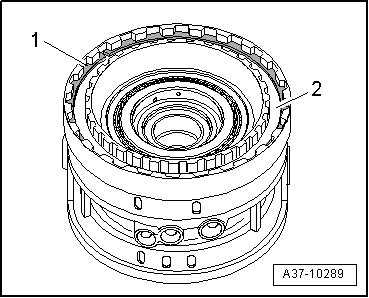

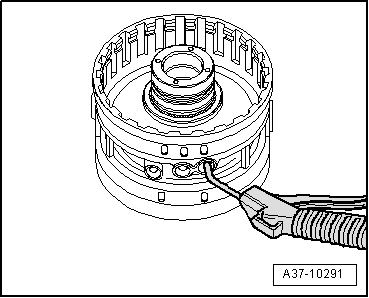

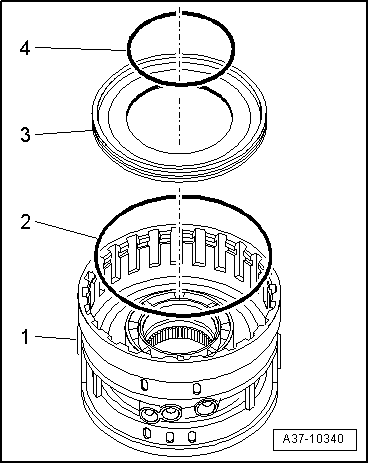

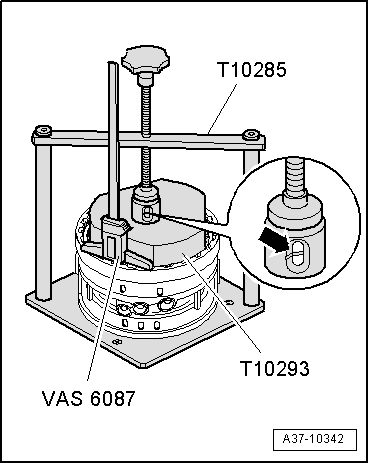

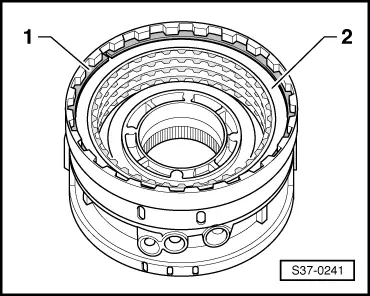

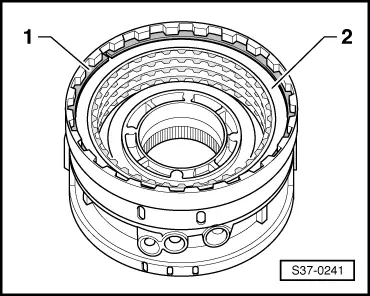

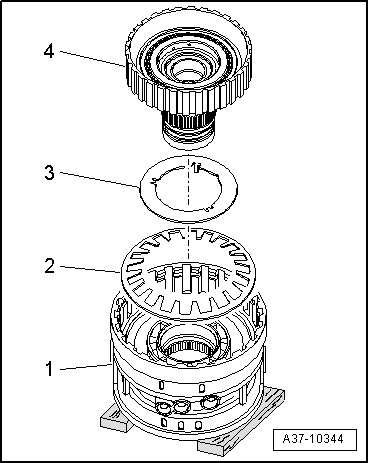

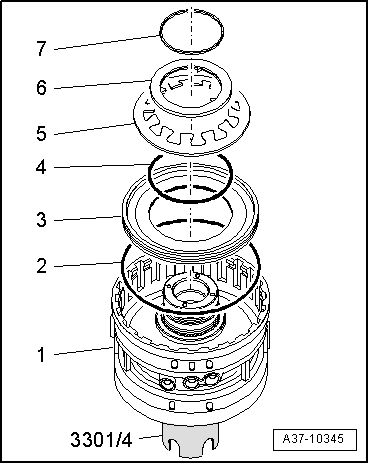

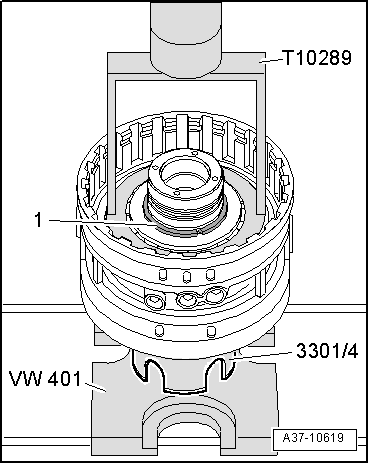

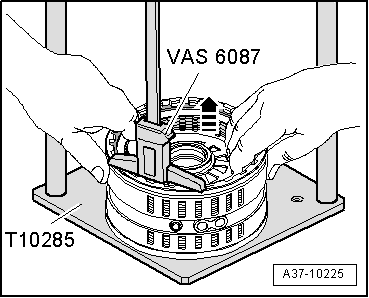

| Put cylinder “D/G”-pos. 1- onto 2 squared timbers of approx. 40 mm. |

| l

| The cylinder “D” points upwards. |

| –

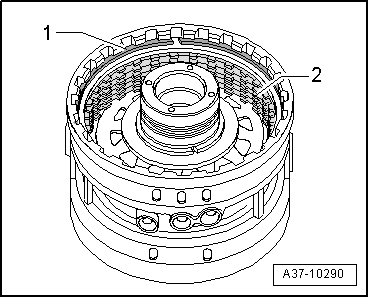

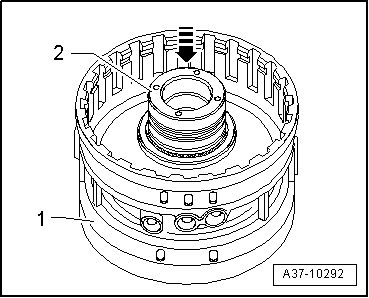

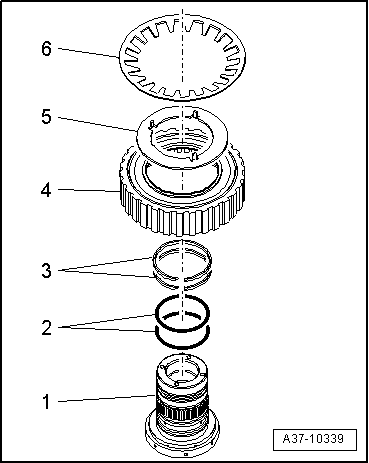

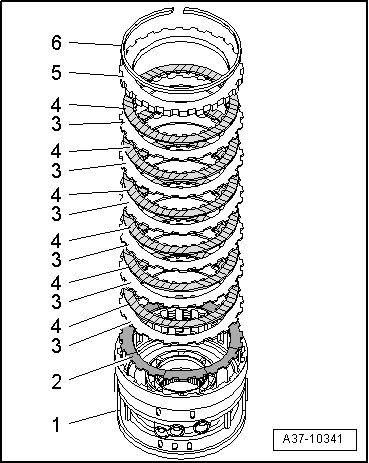

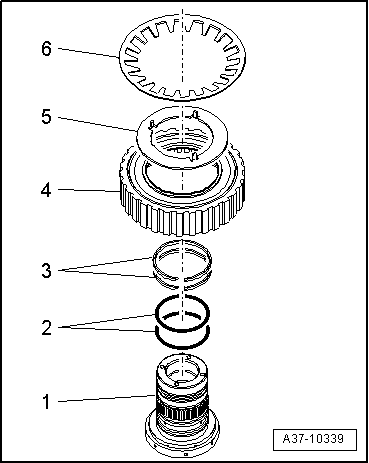

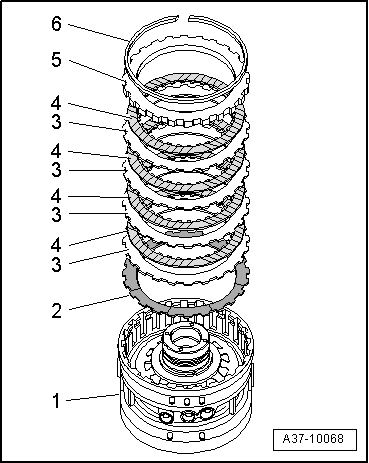

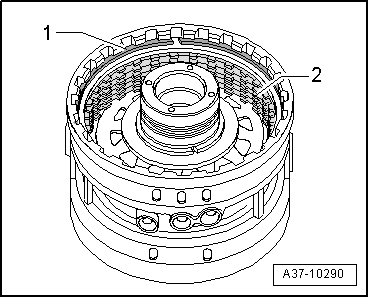

| Insert the disc spring -2- and the retaining washer -3- into cylinder “D/G”. |

| l

| The pegs on the retaining washer point to the cylinder “D/G” and must be inserted into the recesses of the cylinder “D/G” |

| –

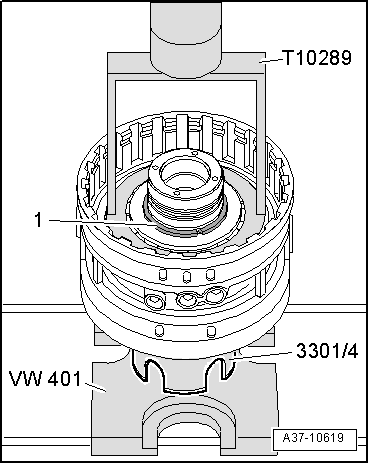

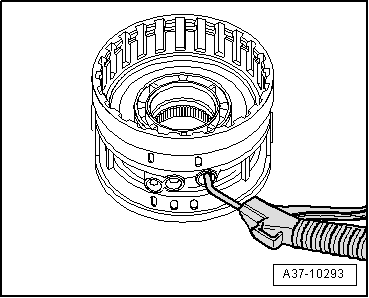

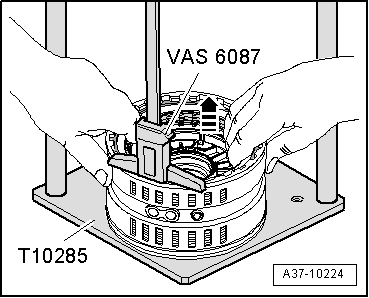

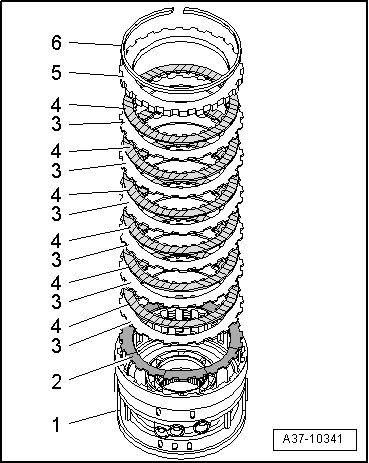

| Take hold of the free wheel -4- in such a way that the free wheel inner race can no longer slip out. |

| –

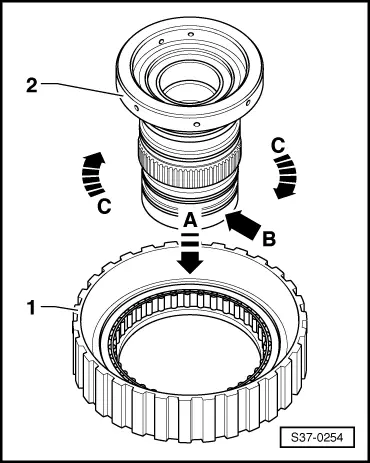

| Then insert the free wheel inner race, to do so press the serration of the free wheel inner race into the serration of the cylinder “D/G”. |

Note | t

| If the free wheel with free wheel cage slips to the bottom when inserting the free wheel inner race, it is positioned again onto the free wheel inner race. |

| t

| After insertion, the free wheel with free wheel cage must only have a low axial play. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution